Process of producing alumina with waste aluminium ash

A technology of alumina and waste aluminum ash, applied in the direction of alumina/hydroxide, solid waste removal, etc., can solve environmental pollution, social environmental pollution has not been reduced, and the use of waste aluminum ash has not found a better way out and other issues, to achieve the effect of low production cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

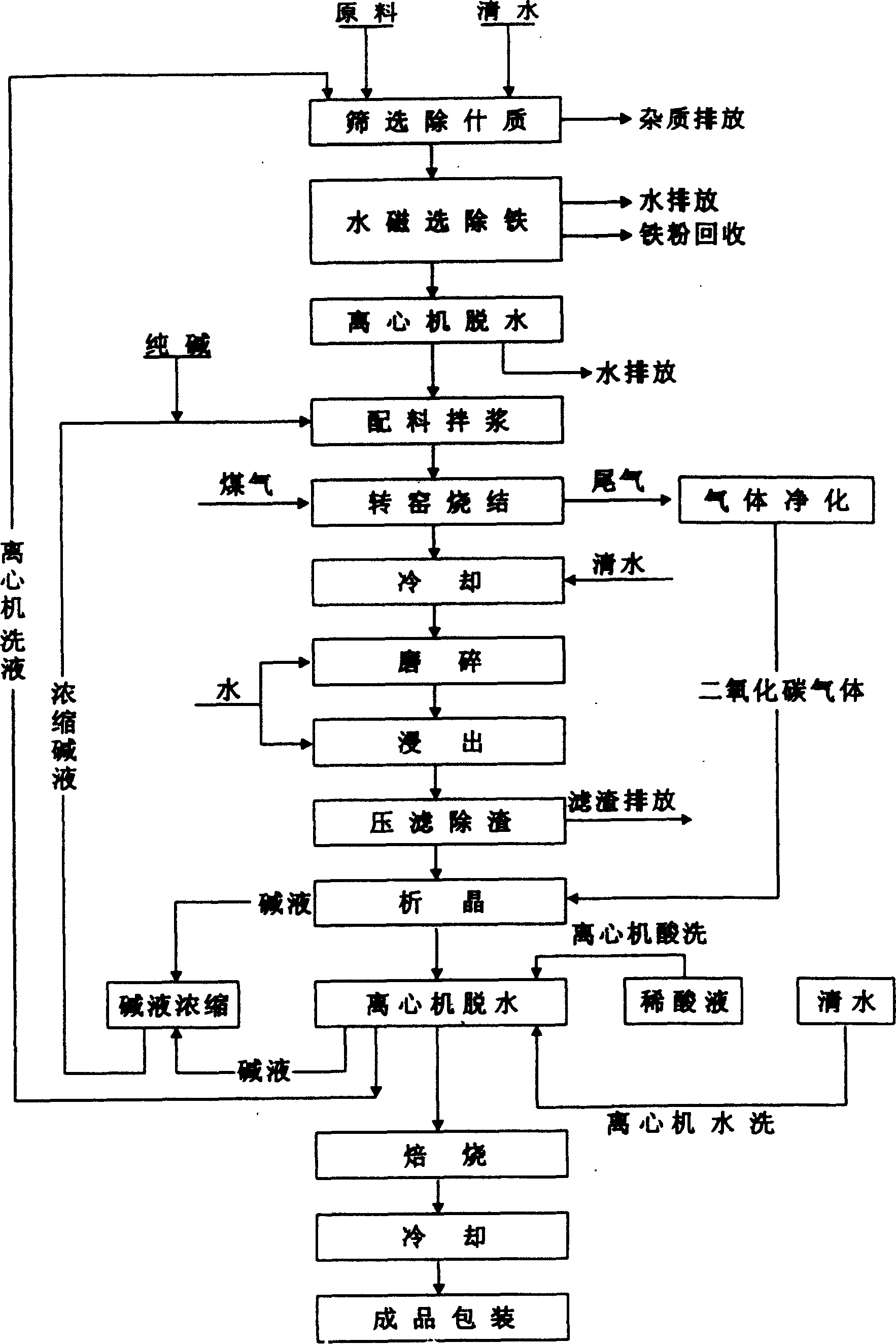

[0025] refer to figure 1 , the production process flow of the embodiment of the present invention is:

[0026] (1) Raw material screening to remove impurities: screen raw aluminum ash with a screen mesh of 60 mesh, add water and centrifuge washing liquid to remove various impurities through multi-stage vibrating screens, and obtain relatively pure aluminum ash;

[0027] (2) Magnetic separation: the screened aluminum ash is removed by a water magnetic separator, the magnetic force is not strictly required, and it is adjusted to be able to absorb iron powder; the water is discharged to recycle the iron powder;

[0028] (3) Dehydration of raw materials: After magnetic separation, the aluminum ash with water is dehydrated by a centrifuge until the water content is generally <15%, and then dehydrated and discharged;

[0029] (4), batching stirring: 31% of the dehydrated aluminum ash enters the batching tank, and adds 31% Na 2 CO 3 and 38% water or add 31% Na 2 CO 3 and a conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com