Preparation method and application of polypyrrole/phytic acid/graphene oxide composite anti-corrosion coating

A graphene composite and composite coating technology, which is applied in the field of metal anti-corrosion and anti-corrosion coating of metal materials, can solve problems such as poor adhesion, pore defects, and lack of good stability, and achieve enhanced bonding force and high Anti-corrosion stability, the effect of good anti-corrosion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031]A kind of preparation method of polypyrrole / phytic acid / graphene oxide composite anticorrosion coating disclosed by the present invention, it comprises the following steps:

[0032] (1) adopt improved Hummers method to prepare graphene oxide, it is uniformly dispersed in deionized water, obtain graphene oxide dispersion liquid;

[0033] (2) Disperse the pyrrole monomer and phytic acid in deionized water, then add the graphene oxide dispersion, stir until uniform, and prepare a mixed electrolyte;

[0034] (3) Using a three-electrode method, using the mixed electrolyte as a supporting solution, electrodepositing a composite coating to obtain the polypyrrole / phytic acid / graphene oxide composite anti-corrosion coating.

[0035] Wherein, the improved Hummers method to prepare graphene oxide specifically includes processes such as oxidation of graphite powder, suction filtration, washing, freeze-drying, grinding, and probe-type ultrasound. More specifically, the mass of graph...

Embodiment 1

[0037] Disperse the pyrrole monomer and phytic acid in deionized water, then add the graphene oxide dispersion, and stir it magnetically for 10 minutes to prepare a uniform mixed electrolyte, in which the concentration of the pyrrole monomer is 0.4mol / L, and the solubility of phytic acid is 0.068mol / L, graphene oxide concentration is 0.25mg / mL;

[0038] The non-working surface of the stainless steel sheet with an area of 10mm×10mm is encapsulated by epoxy resin, while leaving the contact area of the electrode clip, and the working area is polished with 400, 800, 1200, and 2000 mesh SiC sandpaper in sequence, and then deionized Wash with water, acetone and ethanol, and finally dry;

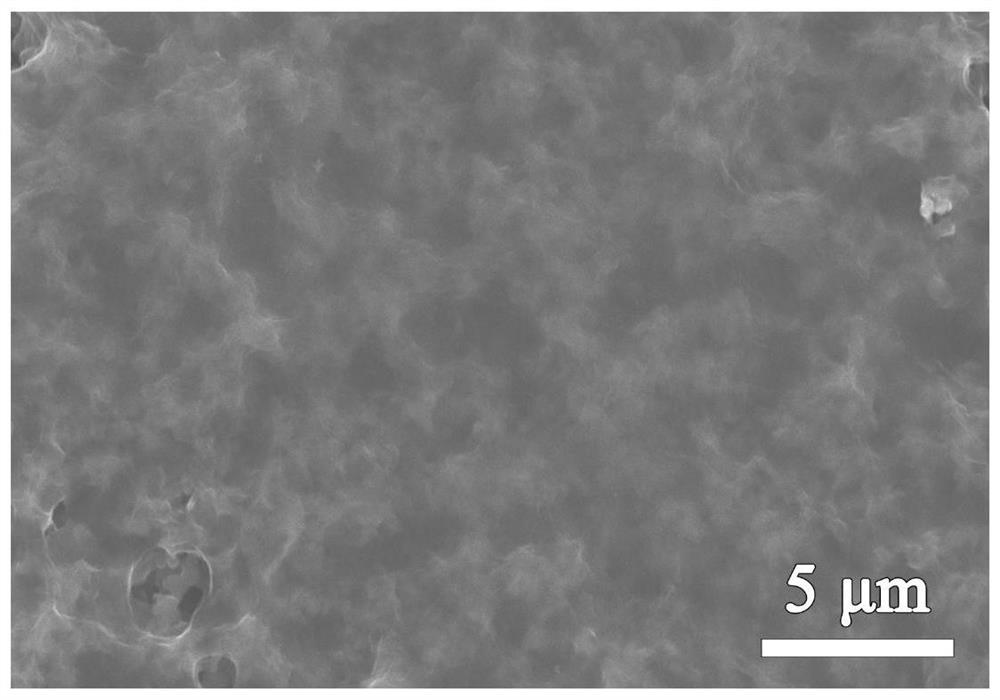

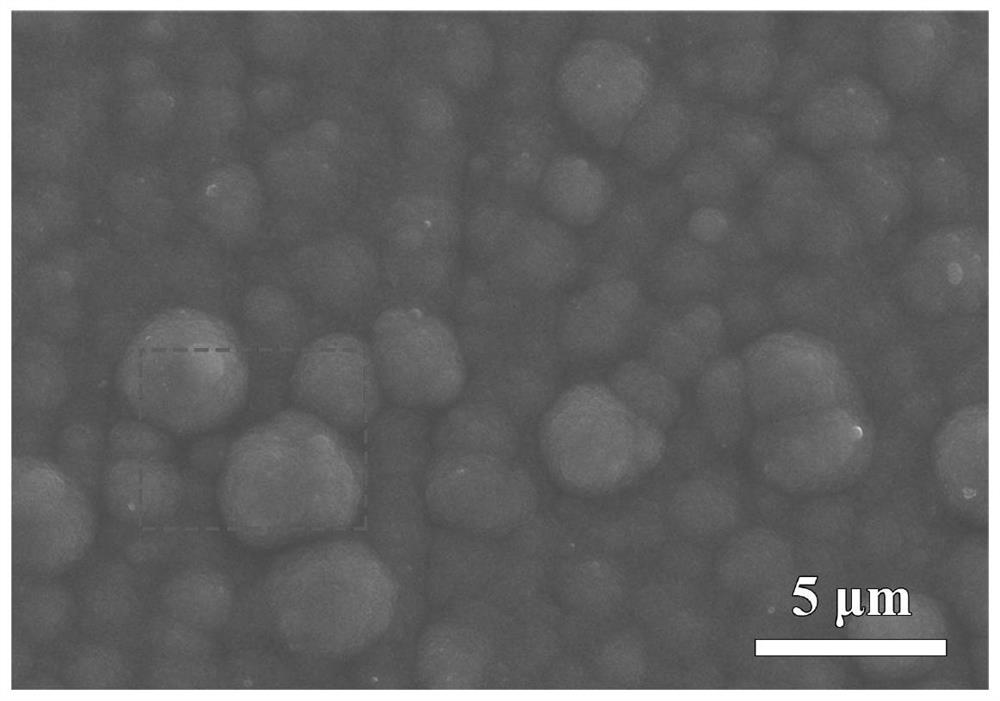

[0039] At room temperature, a three-electrode system is used to prepare the coating by constant current electrodeposition in the above mixed electrolyte, wherein the reference electrode is a saturated calomel electrode, the counter electrode is a platinum sheet electrode, and the working elect...

Embodiment 2

[0052] Disperse the pyrrole monomer and phytic acid in deionized water, then add the graphene oxide dispersion mother liquor, and stir magnetically for 15 minutes under dark conditions, and prepare a well-mixed pyrrole monomer with a concentration of 0.4mol / L and a solubility of phytic acid of 0.1 mol / L, a mixed electrolyte with a graphene oxide concentration of 0.25mg / mL;

[0053] Encapsulate the non-working surface of a stainless steel sheet with an area of 10mm×10mm with epoxy resin, and leave the contact area of the electrode clip on the top, use 400, 800, 1200, 2000 mesh SiC sandpaper to polish the working area in turn, and then use deionized water in turn , acetone and ethanol to clean and degrease, and finally dry;

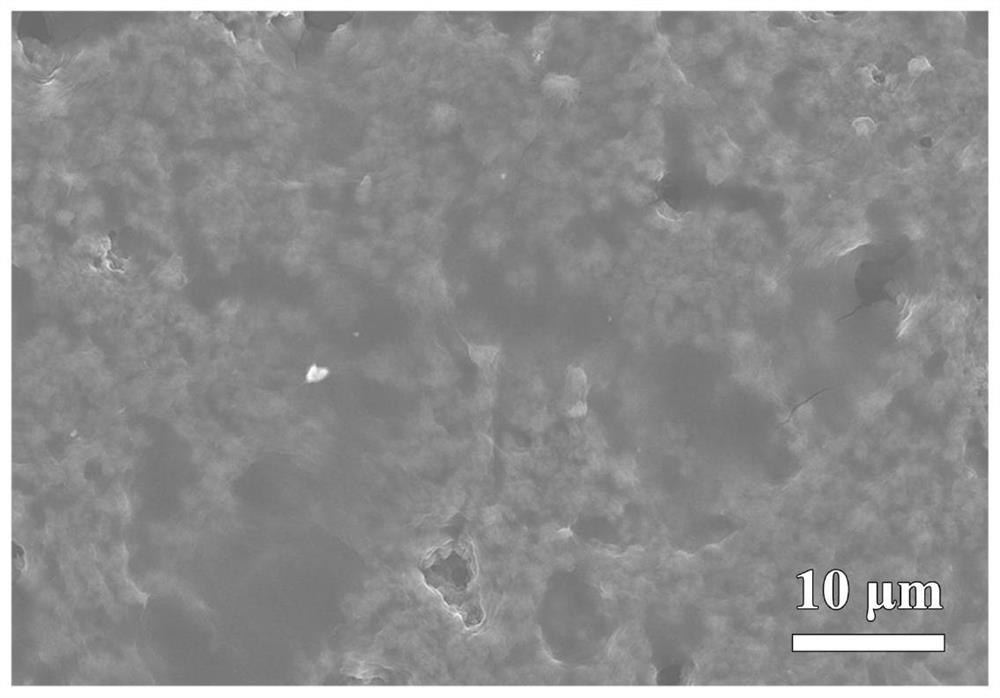

[0054] At room temperature, a three-electrode system is used to prepare the coating by constant current electrodeposition in the above mixed electrolyte, wherein the reference electrode is a saturated calomel electrode, the counter electrode is a platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com