Full-solution-processed multilayered-structure transparent conductive thin film and preparation method thereof

A transparent conductive film, multi-layer structure technology, applied in cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve problems such as poor stability, unengineered, poor adhesion, etc., to achieve environmental stability High performance, excellent electrical performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

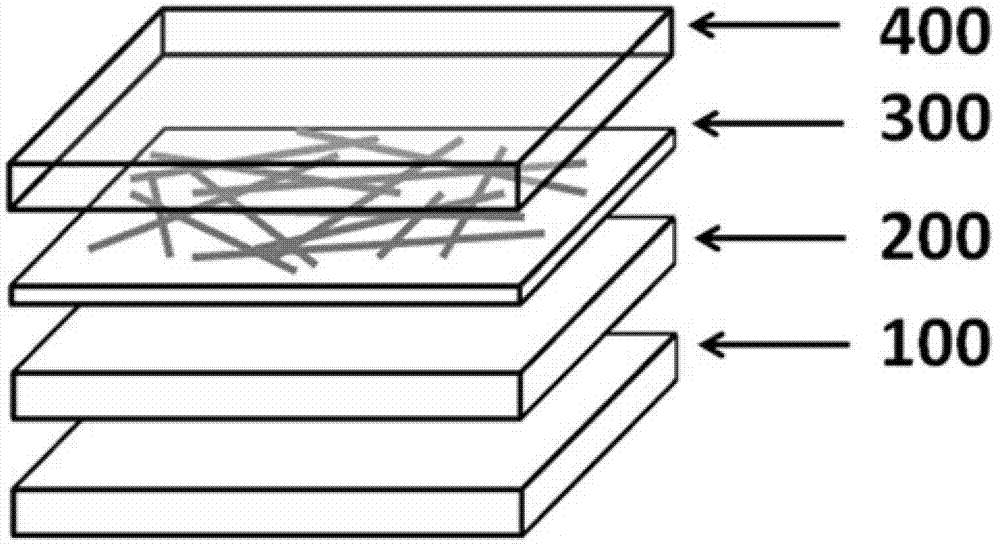

[0058] The preparation method of the full-solution processing multilayer structure transparent conductive film comprises the following steps:

[0059] (1) Prepare the first dielectric reinforcement layer 200 on the planar substrate 100 by using a solution processing method;

[0060] (2) Prepare the metal nanowire layer 300 on the first dielectric reinforcement layer 200 by using a solution processing method;

[0061] (3) Prepare a second dielectric protection layer 400 on the metal nanowire layer 300 by using a solution processing method;

[0062] The first dielectric reinforcement layer 200 is made of any metal oxide semiconductor sol or a mixture of any multiple metal oxide semiconductor sols;

[0063] The second dielectric protection layer 400 is made of any metal oxide semiconductor sol or a mixture of any multiple metal oxide semiconductor sols;

[0064] The metal nanowire layer 300 is made of a metal nanowire solution.

[0065] In the embodiment of the present inventi...

Embodiment 1

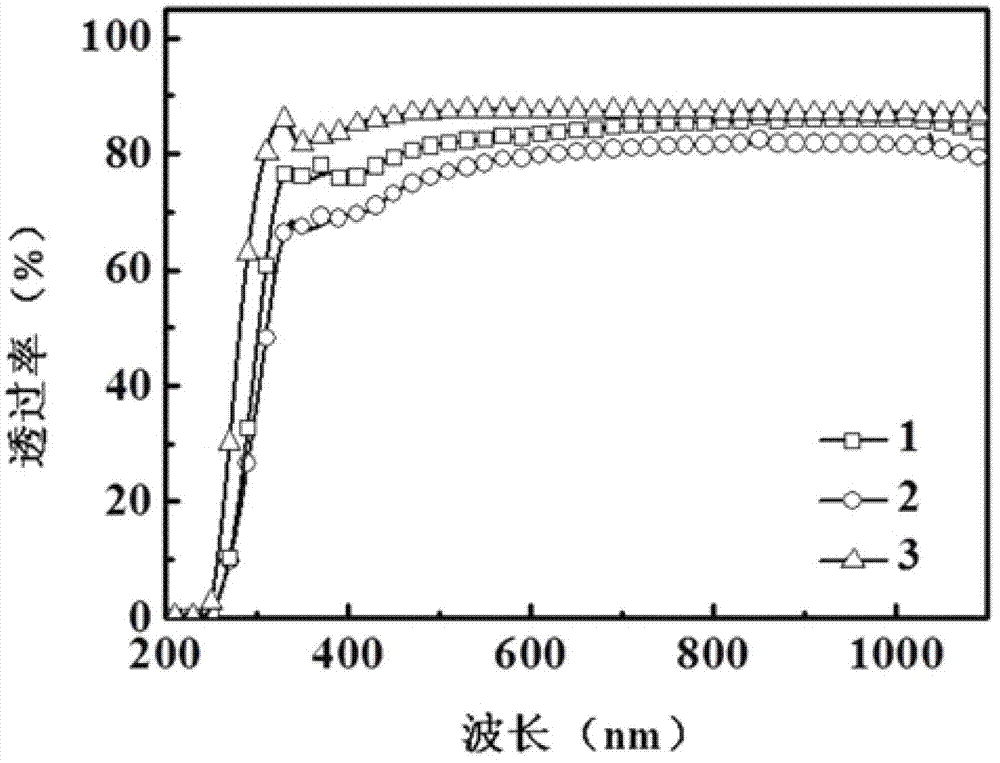

[0092] combine figure 2 , image 3 and Figure 4 Illustrative Example 1

[0093] Preparation of TiOx / AgNW / TiOx multilayer transparent conductive film:

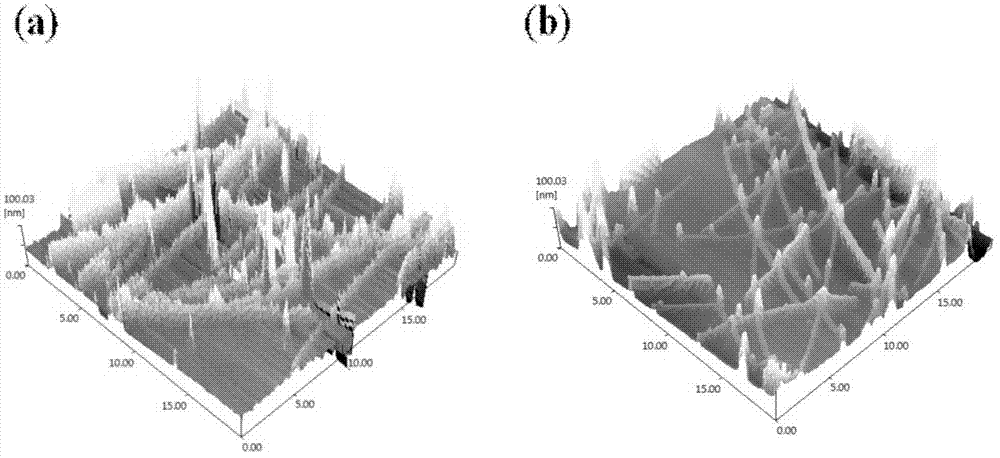

[0094]After the planar substrate 100 was cleaned and dried, TiOx with a thickness of 10 nm was used as the first dielectric reinforcement layer 200, AgNW with a thickness of 70 nm as the metal nanowire layer 300 and a thickness of 10nm of TiOx is used as the second dielectric protection layer 400 to finally form a multi-layer transparent conductive film with the structure of TiOx (10nm) / AgNW (70nm) / TiOx (10nm). Wherein the planar substrate 100 is a glass substrate; the first dielectric reinforcement layer 200 and the second dielectric protection layer 400 are prepared by a spin coating method; the metal nanowire layer 300 is prepared by a drop coating method, and the AgNW has a diameter of 50 nm and a length of 15 μm. The concentration of AgNW solution is 0.2 mg / ml.

[0095] The visible light average transmittance, surfa...

Embodiment 2

[0099] to combine figure 2 and Figure 4 Illustrative Example 2

[0100] V 2 o 5 / AgNW / V 2 o 5 Preparation of a multilayer structured transparent conductive film:

[0101] After cleaning and drying the planar substrate 100, use V 2 o 5 Sol and ethanol-dispersed AgNW solution were sequentially prepared into V with a thickness of 30 nm 2 o 5 As the first dielectric reinforcement layer 200, AgNW with a thickness of 70 nm as the metal nanowire layer 300 and V with a thickness of 40 nm 2 o 5 As the second dielectric protection layer 400, the final structure is V 2 o 5 (30nm) / AgNW(70nm) / V 2 o 5 (40nm) multilayer structure transparent conductive film. Wherein the planar substrate 100 is a glass substrate; the first dielectric reinforcement layer 200 and the second dielectric protection layer 400 are prepared by a spin coating method; the metal nanowire layer 300 is prepared by a drop coating method, and the AgNW has a diameter of 50 nm and a length of 15 μm. The conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com