Self-emulsified epoxy curing agent and reinforced varnish, and preparation method of self-emulsified epoxy curing agent and reinforced varnish

An epoxy curing agent, self-emulsifying technology, used in epoxy resin coatings, coatings, etc., can solve problems such as environmental and human health hazards, and achieve the effects of simplified process, good water resistance, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

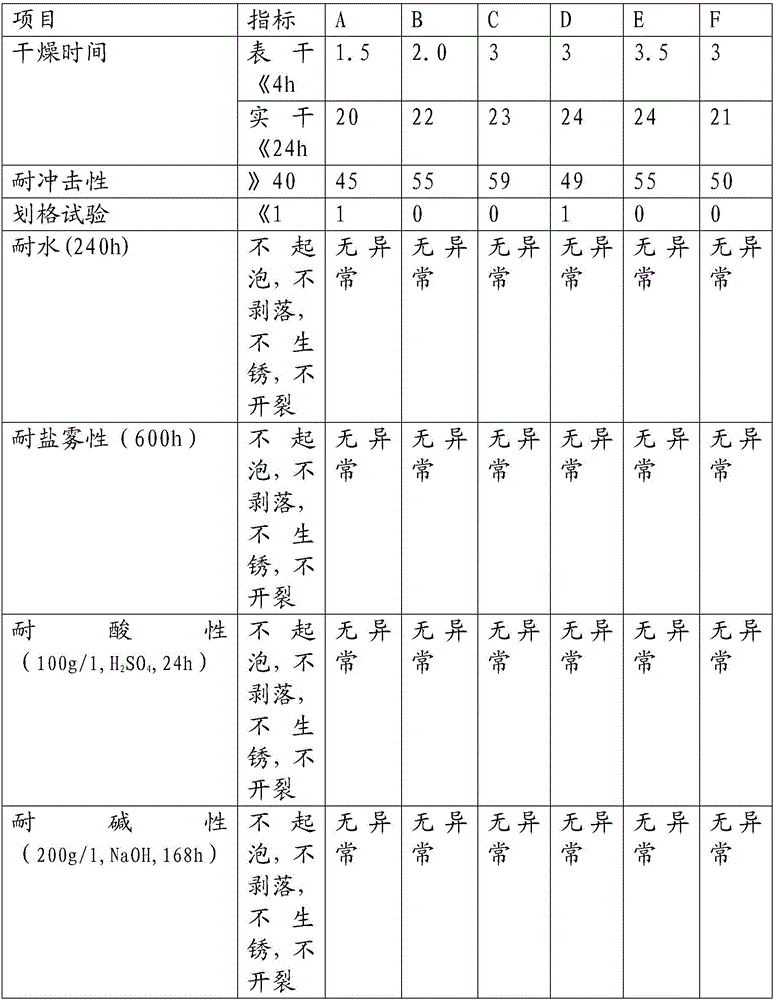

Examples

Embodiment 1

[0030] Add triethylenetetramine and phenyl glycidyl ether in a four-necked flask equipped with a nitrogen feed device, a reflux condenser, a thermometer and a stirrer, and the molar ratio of triethylenetetramine to phenyl glycidyl ether is 1:1 , and then reacted at 55°C for 6.5 hours to obtain a partially blocked amino epoxy adduct. Slowly drip epoxy resin E-51 in the above-mentioned partially blocked amino-based epoxy adduct, the mol ratio of partially blocked amino-based epoxy adduct and epoxy resin E-51 is 2:1.1, then in Reaction was carried out at 60°C for 8 hours to obtain an intermediate product. Add ethylene glycol diglycidyl ether dropwise to the above intermediate product, the molar ratio of the intermediate product to ethylene glycol diglycidyl ether is 2:0.6, carry out the addition reaction at 70°C for 3 hours, and the self-emulsifying type can be obtained Epoxy curing agent A.

[0031] According to the weight ratio of 1:0.5:1, it is taken from emulsified epoxy cu...

Embodiment 2

[0033] Add diethylenetriamine and phenyl glycidyl ether in a four-necked flask equipped with a nitrogen feed device, a reflux condenser, a thermometer and a stirrer, and the molar ratio of diethylenetriamine to phenyl glycidyl ether is 1:1.5 , and then reacted at 90°C for 2.5 hours to obtain a partially blocked amino epoxy adduct. Slowly drip epoxy resin E-51 in the above-mentioned partially blocked amino epoxy adduct, the mol ratio of partially blocked amino epoxy adduct and epoxy resin E-51 is 2:1.5, then in React at 80°C for 4 hours to obtain an intermediate product. Add butyl diglycidyl ether dropwise to the above intermediate product, the molar ratio of intermediate product to butyl diglycidyl ether is 2:0.8, and carry out addition reaction at 85°C for 4.5 hours to obtain self-emulsifying epoxy Curing agent B.

[0034] Take emulsified epoxy curing agent B, epoxy resin E-44, and water in a weight ratio of 1:1:2, mix them with water, and stir for 5 minutes at a speed of 5...

Embodiment 3

[0036] Add polyether amine (molecular weight is 230) and butyl glycidyl ether in the four-neck flask that nitrogen feeds device, reflux condenser, thermometer and stirrer are housed, the mol ratio of polyether amine and butyl glycidyl ether is 1:2.2, and then reacted at 80°C for 6 hours to obtain a partially blocked amino epoxy adduct. Slowly drip epoxy resin E-44 in the above-mentioned partially blocked amino-based epoxy adduct, the mol ratio of partially blocked amino-based epoxy adduct and epoxy resin E-44 is 2:1.8, then in The reaction was carried out at 65°C for 5.5 hours to obtain an intermediate product. Add propylene glycol diglycidyl ether dropwise to the above intermediate product, the molar ratio of the intermediate product to propylene glycol diglycidyl ether is 2:1.5, and carry out the addition reaction at 75°C for 5.5 hours to obtain a self-emulsifying epoxy curing agent c.

[0037] According to the weight ratio of 1:1.5:2.5, it is taken from emulsified epoxy c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com