Inorganic dry powder solid color prime coat and application thereof

An inorganic dry powder, solid color technology, applied in the direction of coating, can solve the problem of poor color adhesion of paint, and achieve the effect of good hiding power, good tinting strength and good sandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the components of the inorganic dry powder solid color primer include:

[0061] Calcium carbonate 20g; vinyl acetate / styrene copolymer 580g;

[0062] Or can also include:

[0063] Iron oxide yellow 50g; silicon carbide 200g;

[0064] And defoamer 2g; air-entraining agent 1g; water reducer 2g; thixotropic rheological agent 2g; thickener 1g; anti-cracking agent 1g;

[0065] Wherein, the defoamer is alcohol phosphate; the air-entraining agent is fatty alcohol sodium sulfate; the water reducer is polycarboxylate; the thixotropic rheological agent is polyamide wax; The thickener is polymethacrylic acid; the anti-cracking agent is polypropylene fiber.

[0066] The above-mentioned components are mixed to prepare the inorganic dry powder solid-color primer, which is applied on buildings by adding water on site and stirring evenly.

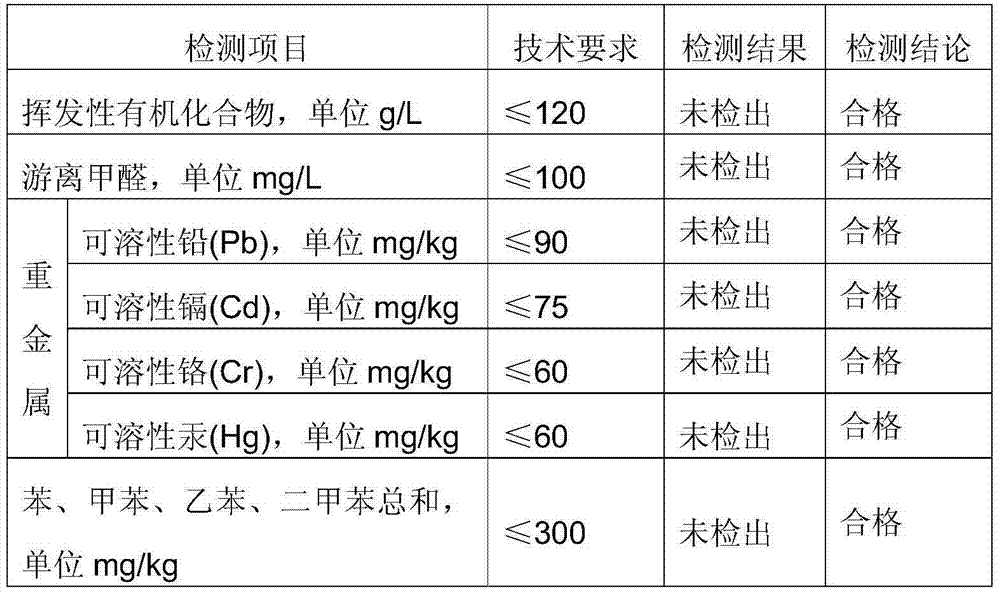

[0067] The inorganic dry powder solid color primer described in this example complies with the relevant provisions in JG / T2...

Embodiment 2

[0069] In this embodiment, the components of the inorganic dry powder solid color primer include:

[0070] Calcium sulfate 80g; polyvinyl acetate 600g;

[0071] Or can also include:

[0072] Phthalocyanine 80g; Boron nitride 100g;

[0073] And defoamer 2g; air-entraining agent 1g; water reducing agent 2g; anti-cracking agent 1g;

[0074] Wherein, the defoamer is polyether modified silicone oil; the air-entraining agent is decanol polyoxyethylene ether; the water reducing agent is lignosulfonate; the anti-cracking agent is polypropylene fiber.

[0075] The above-mentioned components are mixed to prepare the inorganic dry powder solid-color primer, which is applied on buildings by adding water on site and stirring evenly.

[0076] The inorganic dry powder solid color primer described in this example complies with the relevant provisions in JG / T210-2007 "Primer Coating for Interior and Exterior Walls of Buildings" and GB / 18582-2008 "Limits of Harmful Substances in Interior De...

Embodiment 3

[0078] In this embodiment, the components of the inorganic dry powder solid color primer include:

[0079] Tetracalcium aluminoferrate 100g; Vinyl acetate / ethylene copolymer (EVA) 800g;

[0080] Or can also include:

[0081] Cobalt blue 30g; Talc powder 150g;

[0082] And defoamer 2g; thickener 1g.

[0083] Wherein, the defoamer is alcohol phosphate; the thickener is polymethacrylic acid.

[0084] The above-mentioned components are mixed to prepare the inorganic dry powder solid-color primer, which is applied on buildings by adding water on site and stirring evenly.

[0085] The inorganic dry powder solid color primer described in this example complies with the relevant provisions in JG / T210-2007 "Primer Coating for Interior and Exterior Walls of Buildings" and GB / 18582-2008 "Limits of Harmful Substances in Interior Decoration Materials and Interior Wall Coatings" Require.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com