Plastics and preparation method thereof

A technology for plastics and products, which is applied in the field of plastic products and its preparation, and can solve the problems of uneven surface, poor adhesion between the primer layer and the substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

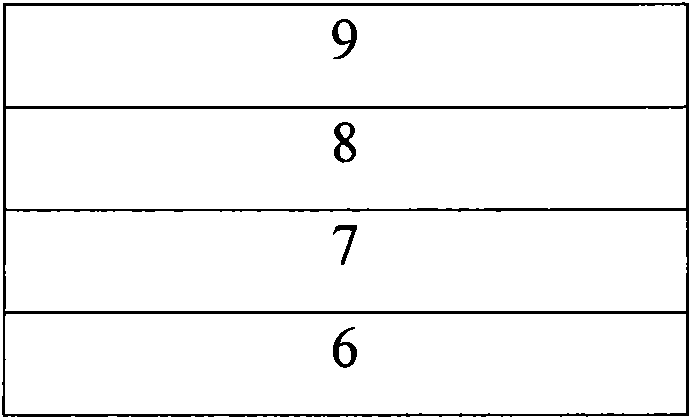

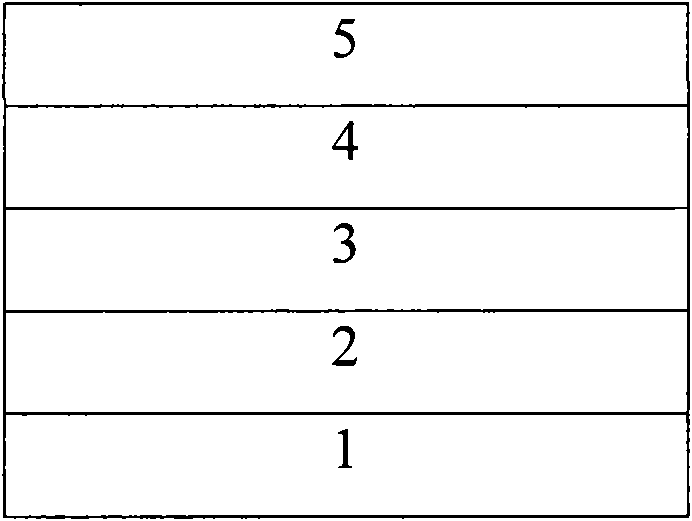

[0020] The present invention provides a method for preparing plastic products, wherein the method includes sequentially forming a first metal layer 2 , a primer layer 3 , a second metal layer 4 and a topcoat layer 5 on the surface of a plastic substrate 1 .

[0021] Wherein, the coating composition used when forming the first metal layer 2, the primer layer 3, the second metal layer 4 and the top coat layer 5 and the thicknesses of the attached layers are all the same as described above, and will not be repeated here. repeat.

[0022] The method of forming the first metal layer 2 may be sputtering plating. The sputtering method is a technique of physical vapor deposition. Ion sputtering is to use the high-speed motion of positive ions generated by gas discharge to bombard the target as the cathode under the action of an electric field, so that the atoms or molecules in the target It escapes and precipitates on the surface of the substrate to be plated to form the required fil...

Embodiment 1

[0037] This example is used to prepare the plastic product A1 provided by the present invention, and to measure its adhesion and appearance.

[0038] (1) Clean nylon plus 50% glass fiber (EMS GV-5H) with ultrasonic waves (3-5KW, 1 hour), then scrub with white electric oil (Dongtai DT-618), and then use alcohol (concentration: 95%) )scrub.

[0039] (2) Use UHS-360B (manufacturer: UHS) sputtering coating equipment, in nitrogen at 270 cm 3 / second, the power is 4 kilowatts, and the coating time is 1 second to add a coating on the surface of nylon and 50% glass fiber, and the surface is coated with an aluminum metal layer with a thickness of 5 nanometers.

[0040] (3) Use Cashew Vm8000 as the primer coating, spray the primer coating on the aluminum metal layer obtained in the above step (2), and use 4 UV lamps with a power of 380 watts after preheating at a temperature of 45°C for 5 minutes. Cured by lamp irradiation, UV energy is 1200 mJ / cm 2 , a primer layer with a thickness...

Embodiment 2

[0047] This example is used to prepare the plastic product A2 provided by the present invention, and to measure its adhesion and appearance.

[0048] Plastic product A2 was prepared in the same manner as in Example 1, except that in step (2), zinc was used instead of aluminum to form a zinc metal layer with a thickness of 40 nanometers, and the intermediate paint layer was not formed.

[0049] The plastic product A2 was obtained, and its adhesion and appearance properties were measured in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com