Microporous acrylic adhesive tape

An acrylic and microporous technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve poor temperature resistance and reliability, product viscosity and performance attenuation, LED lamp tube rupture, etc. problems, to achieve the effect of improving reliability, soft light, and reducing the chance of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

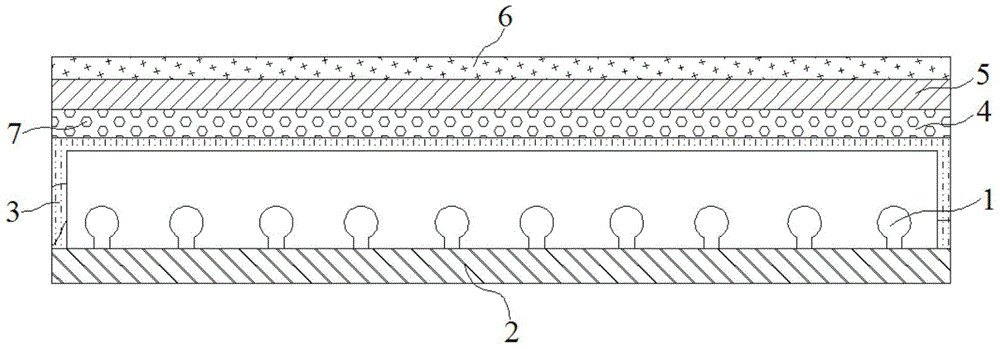

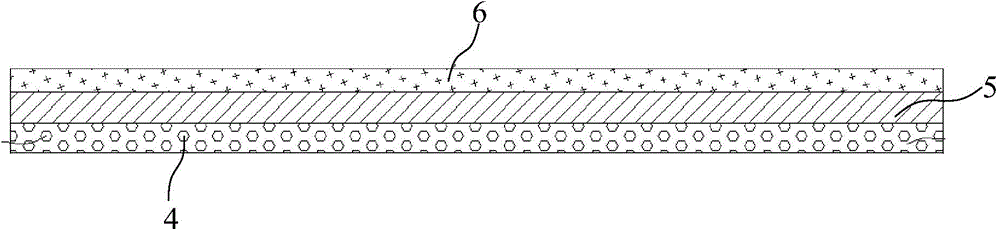

Image

Examples

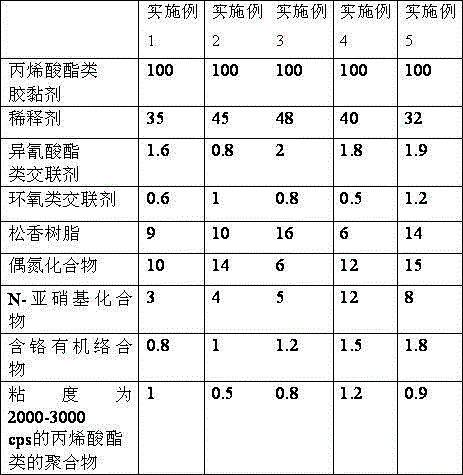

Embodiment 1

[0036] The diluent of embodiment 1 is toluene; The diluent of embodiment 2 is ethyl acetate; The diluent of embodiment 3 is acetone; The diluent of embodiment 4 is toluene and ethyl acetate according to the mixed diluent of 1:1; The diluent in Example 5 is a 1:1 mixed diluent of toluene and acetone.

[0037] The polyester film layer 5 of embodiment 1 is a PET film layer; the polyester film layer 5 of embodiment 2 is a PA film layer; the polyester film layer 5 of embodiment 3 is a PP film layer; the polyester film layer of embodiment 4 5 is a PBT film layer; the polyester film layer 5PA film layer of embodiment 5.

[0038] Mix the above components according to the conventional process and stir at high speed, use a high-speed coating machine to coat the above-mentioned matte adhesive on the surface of the polyester film, and pass through the oven (temperature: 60°C, 75°C, 85°C, 110°C, 125°C, 135°C, 90°C) to volatilize the solvent, cure and mature before coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com