Printed circuit board

A technology of printed circuit boards and substrates, which is applied to printed circuit components, electrical connection printed components, etc., can solve problems such as increasing the firmness of wire welding, and achieve the effect of protecting reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

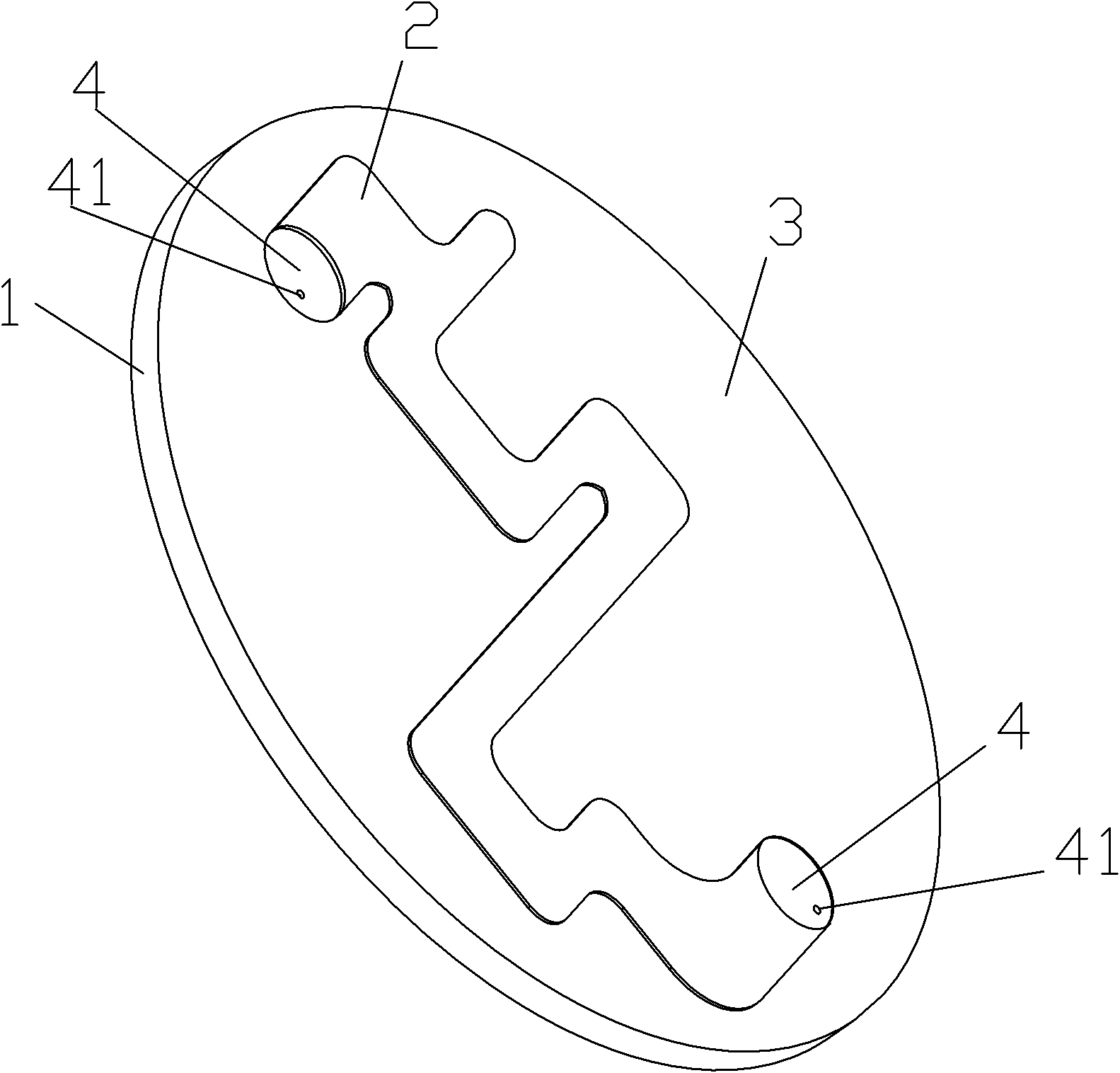

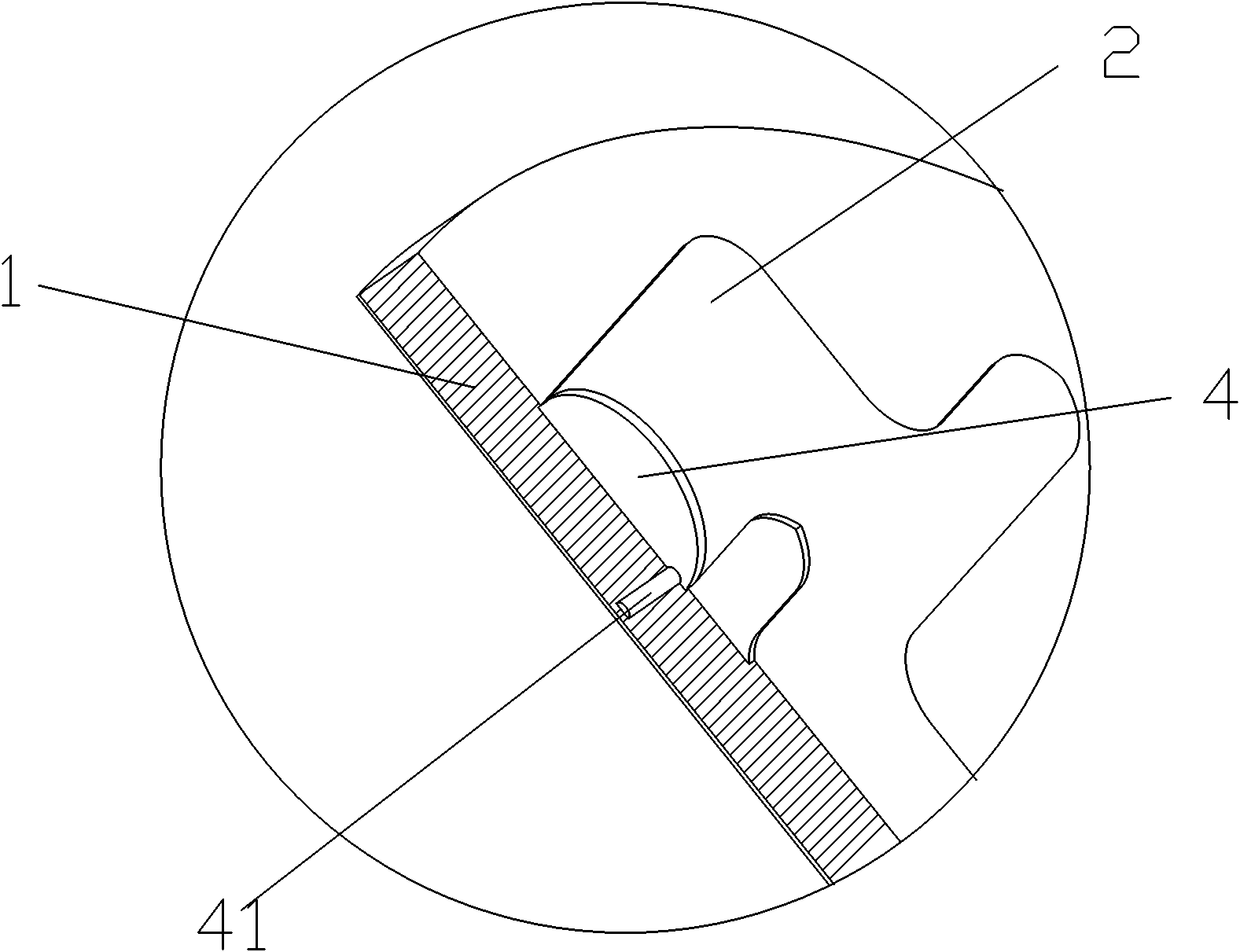

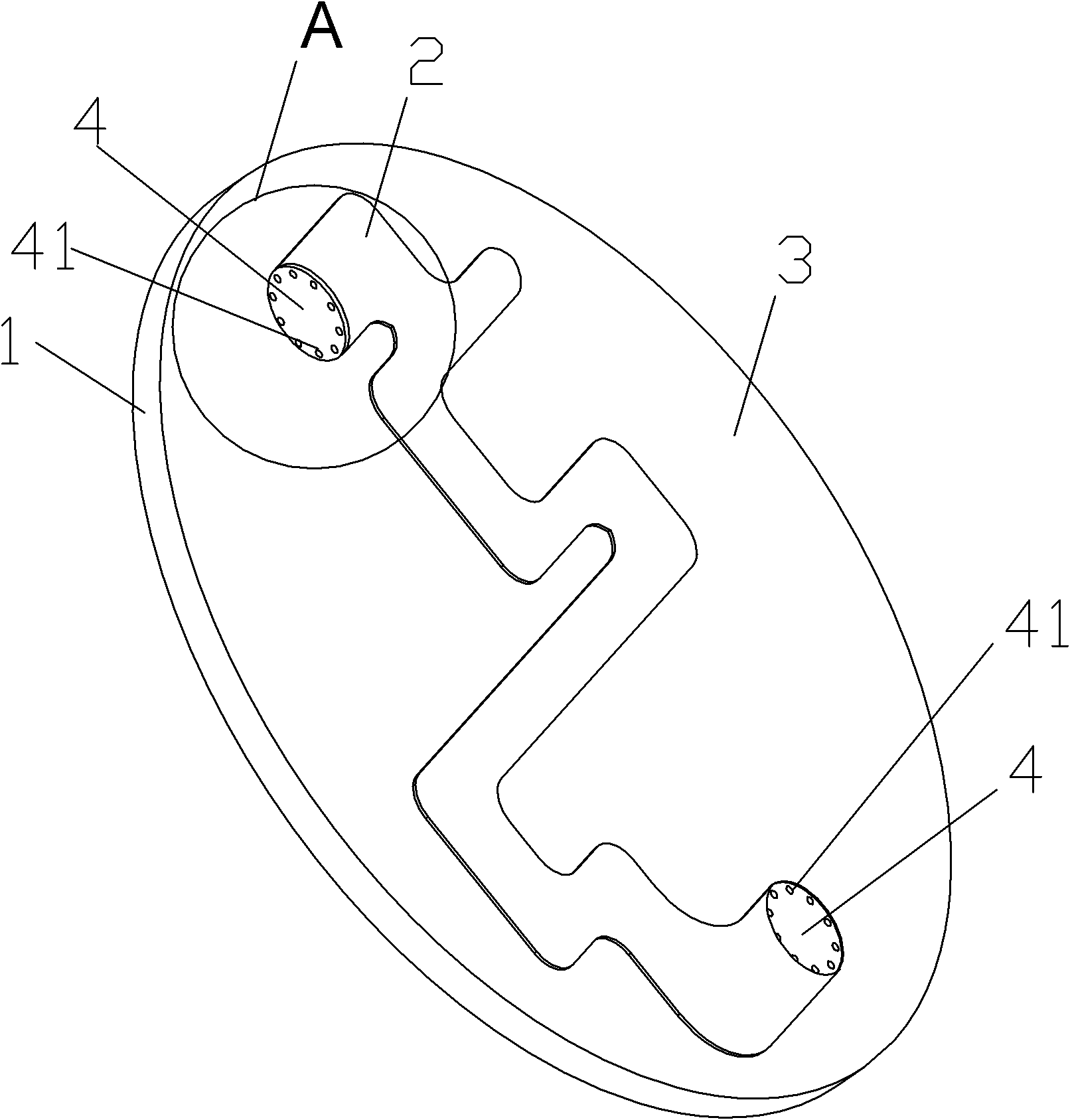

[0024] The schematic diagram of the printed circuit board structure of the preferred embodiment of the present invention is as figure 1 shown, see also figure 2 , which includes a substrate 1, a copper skin 2 laid on the front of the substrate 1, and a front insulating layer 3, the front insulating layer 3 is pressed outside the copper skin 2, and at least one exposed copper area 4 is left. A hole 41 is provided along the thickness direction of the substrate 1 in the exposed copper area 4 , and a copper skin 2 is attached to the inner wall of the hole 41 . By setting the hole 41 along the thickness direction of the substrate 1 in the exposed copper area 4 of the printed circuit board, and laying the copper skin 2 on the inner wall of the hole 41, the solder joint of the wire in the exposed copper area 4 is like a hand firmly grasping Like the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com