Container lid of operation type vacuum valve

A technology for sealing containers and vacuum valves, which is applied in the direction of containers, caps, and seals. It can solve the problems that the mold cannot be separated, the ring groove is impossible, and the traditional technology cannot actually adapt to industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

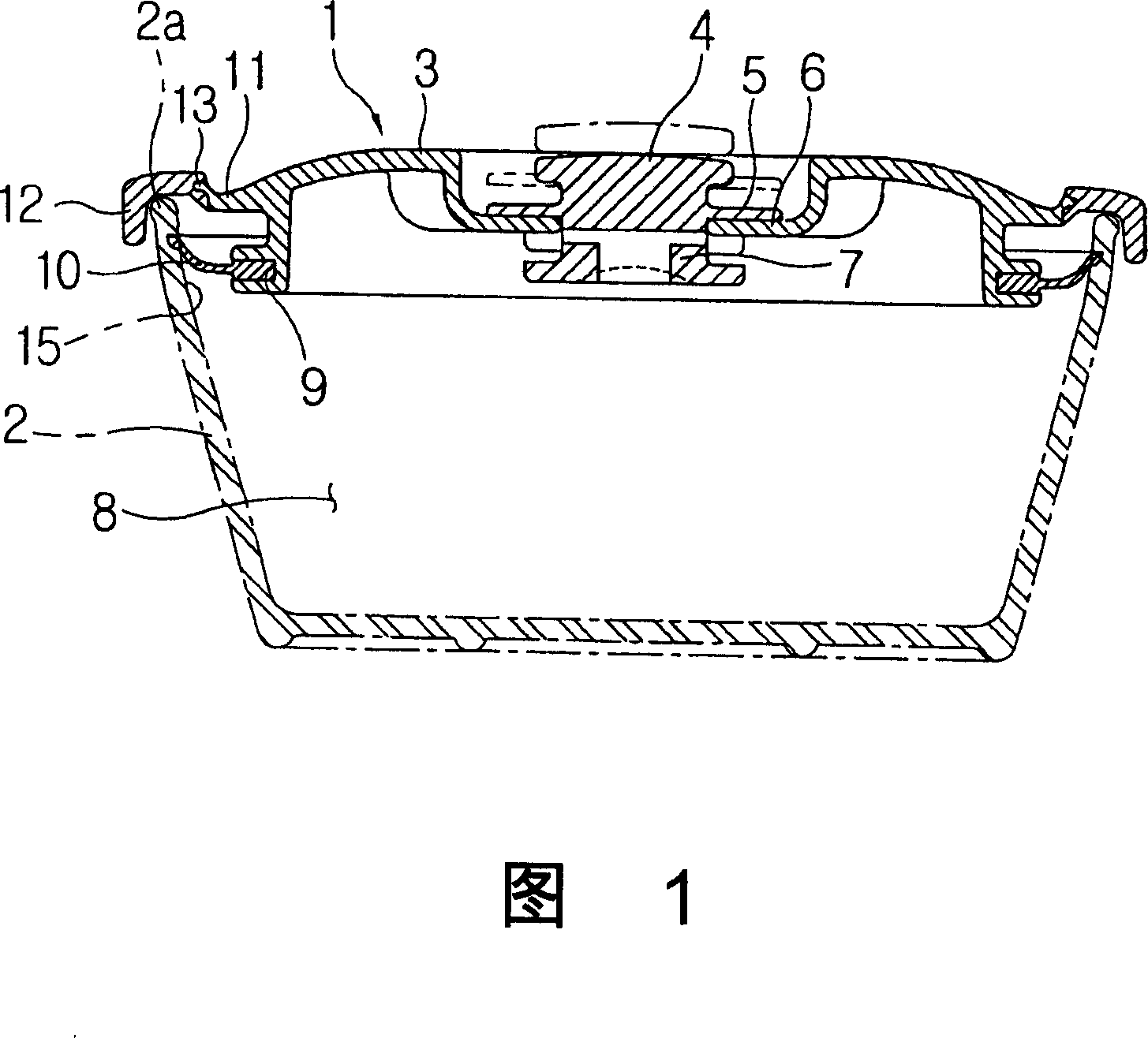

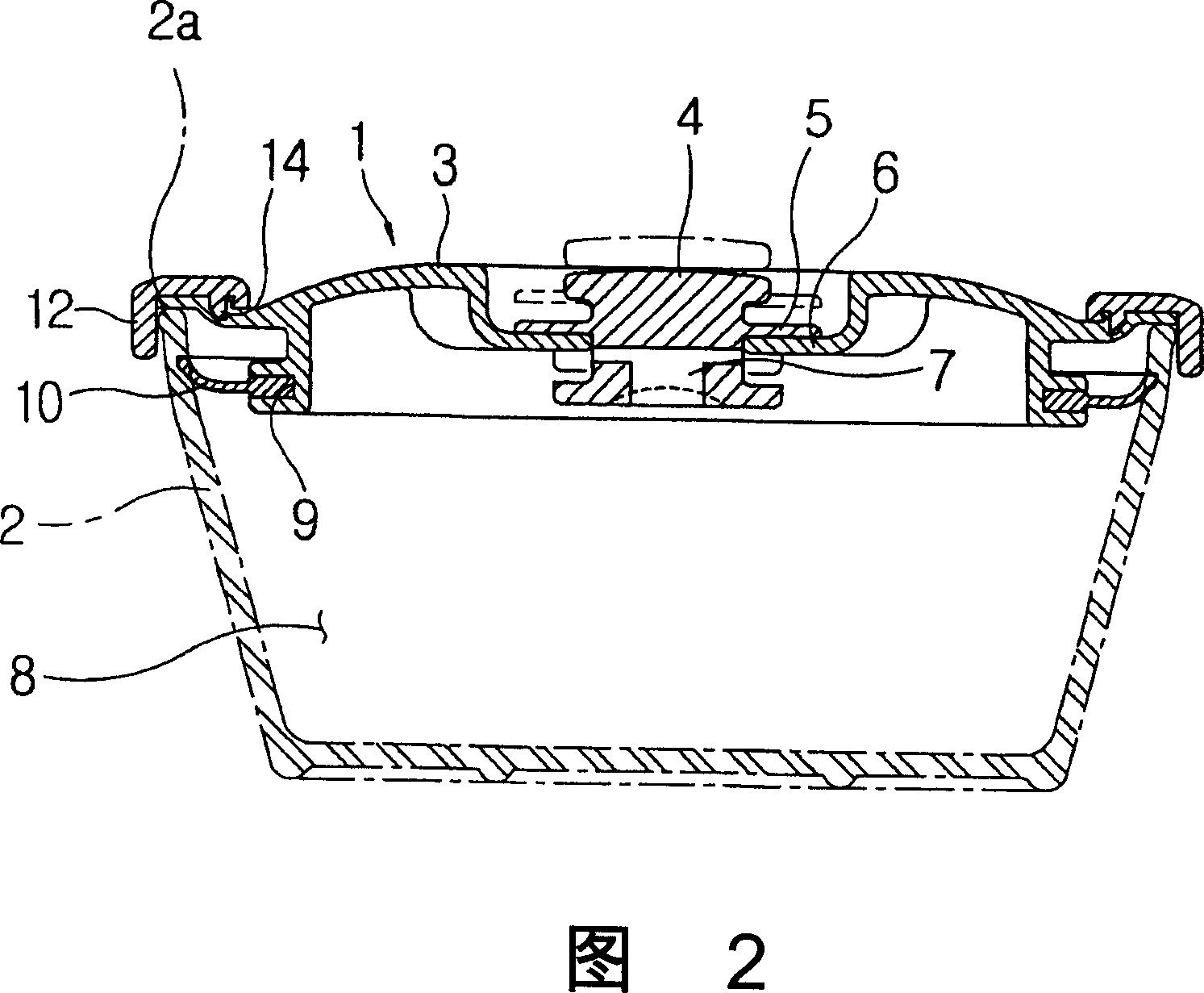

[0015] Fig. 1 is a view showing a sealed container lid with an operating vacuum valve according to the present invention, and Fig. 2 is a view showing a belt of a double injection molding structure according to a specific example embodiment of the present invention. Double-injection structure of the airtight container lid of the operation type vacuum valve.

[0016] In the figure, reference numeral 1 denotes a container cap, and 2 denotes a container body, where the container cap 1 is opened or closed.

[0017] A vacuum valve 4 for opening or closing the lid is installed on the lid body 3 of the container lid 2 . When the valve seat 5 of a vacuum valve 4 is lifted off the valve seat 6, the inside 8 of the container body 2 is opened to the outside through the valve hole 7. When it is pressed against the valve seat 6, the valve hole 7 is closed, and the inside 8 of the container body 2 is not communicated with the outside.

[0018] An annular groove 9 is formed on the cover bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com