Mascara brush

a mascara brush and lash technology, applied in the field of mascara brushes, can solve the problems of mascara brushes that cannot be easily reattached, eyelashes may be tangled or adhered to each other, and the mascara brush may not be able to adhere to each other, so as to improve workability and productivity, reduce production costs, and simplify the manufacturing and assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

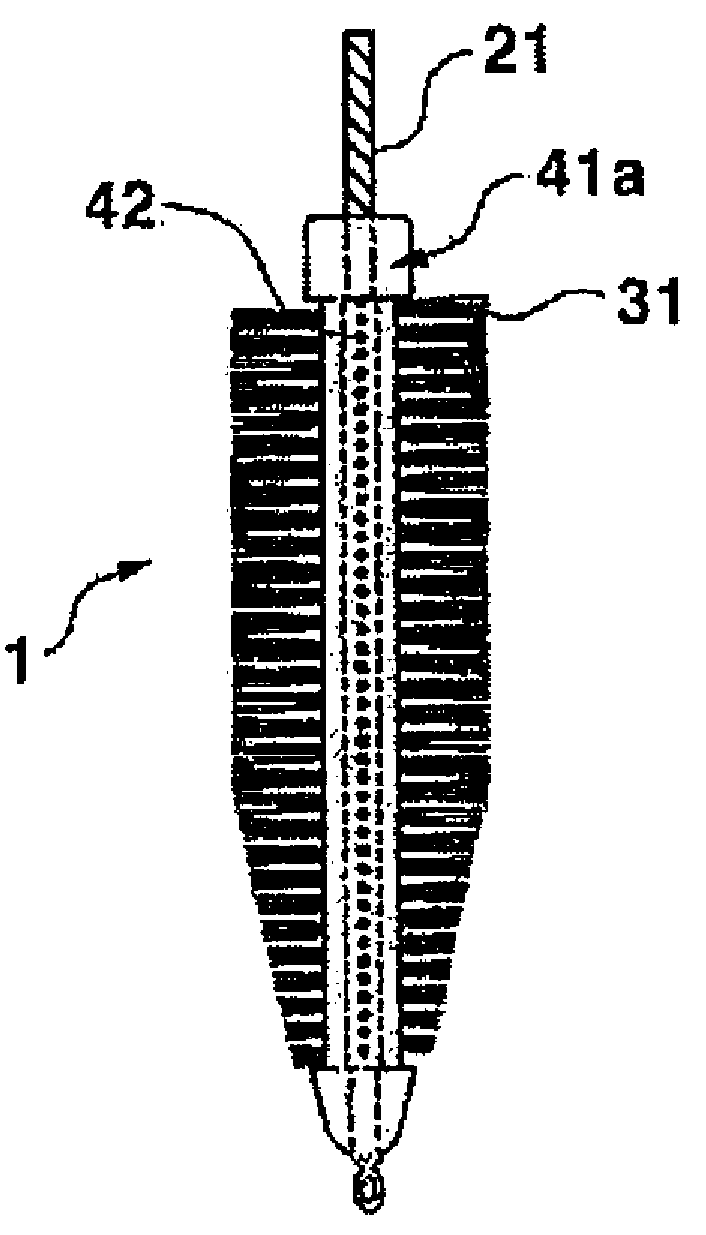

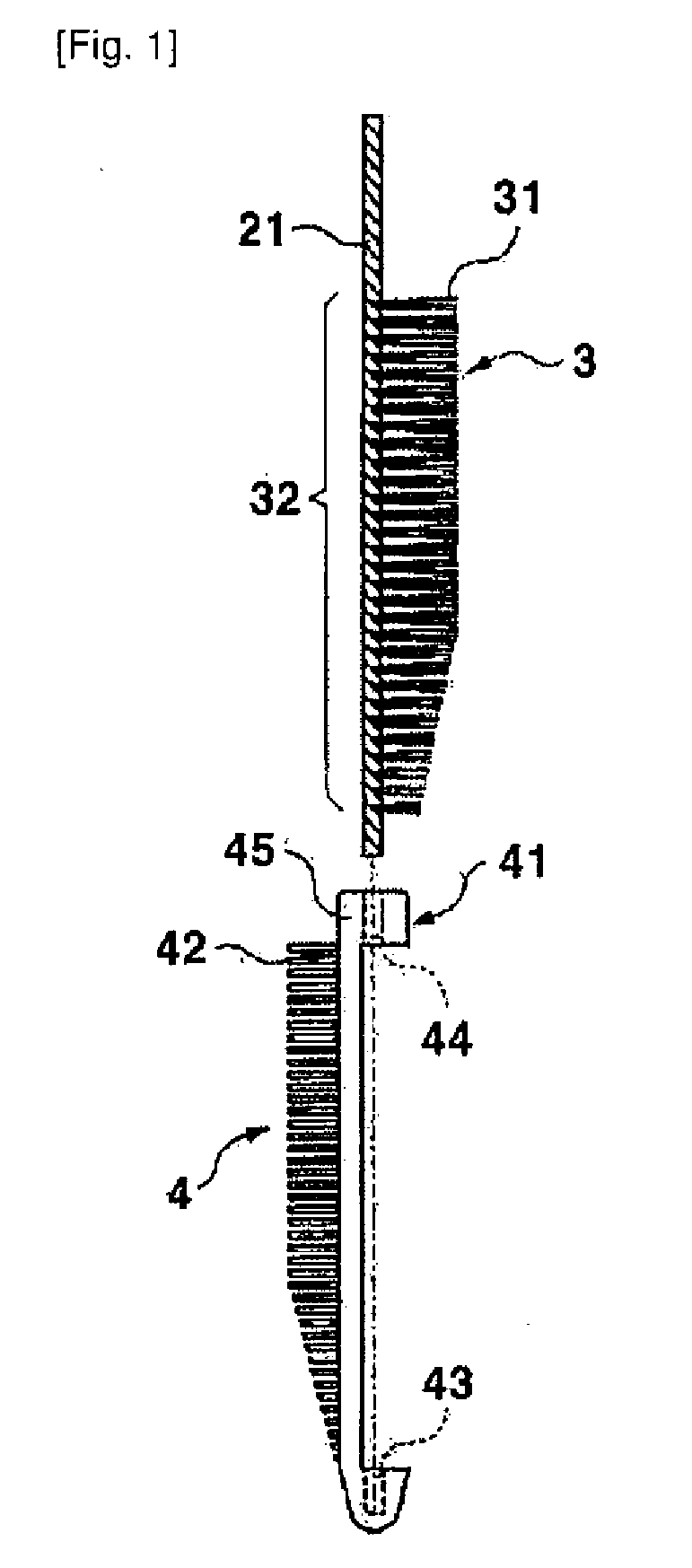

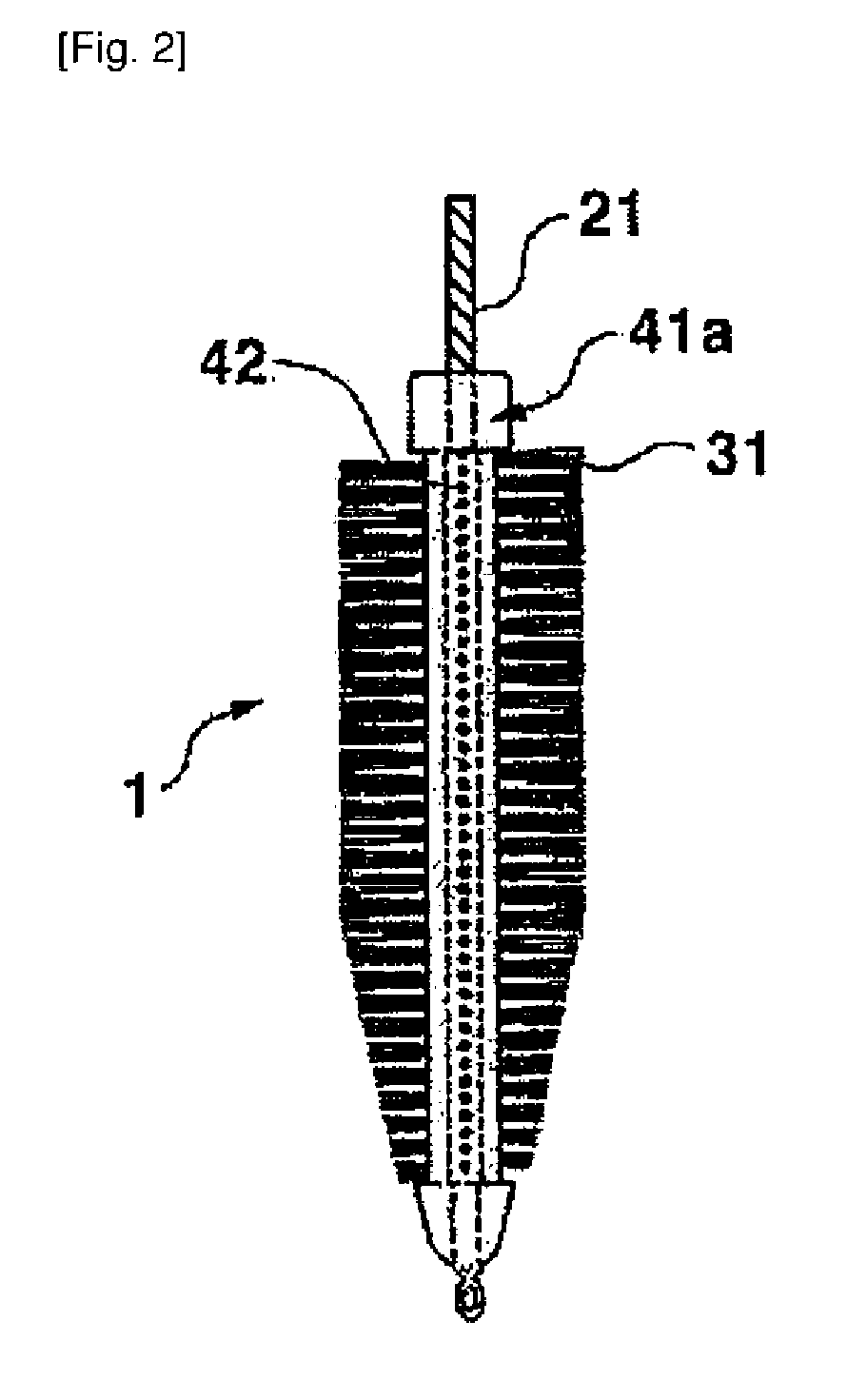

[0039]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the attached drawings.

[0040]FIGS. 3 and 4 are front views, plan views and side views of mascara brushes according to a first embodiment of the present invention. As shown in the drawings, the mascara brush according to the first embodiment includes a bristle part 120, which is formed by integrally injection-molding a cylindrical brush body 110 and bristles 121, which are formed around the brush body 110 to apply mascara to eyelashes, and a comb part 130, which tidies the eyelashes and is formed through a double injection molding process such that part of the comb part 130 is embedded in the brush body 110.

[0041]The brush body 110 has an approximately cylindrical shape, and is coupled to a brush handle (not shown). A coupling boss 111, through which the brush body 110 is coupled to the brush handle, is provided on one end of the brush body 110.

[0042]The bristle part 120 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com