Carbon supported noble metal catalyst and method for preparing same

A precious metal catalyst, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. The problem of metal particle diameter in large catalysts can achieve the effect of improving battery performance, easy large-scale preparation, improving catalytic activity and anti-toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

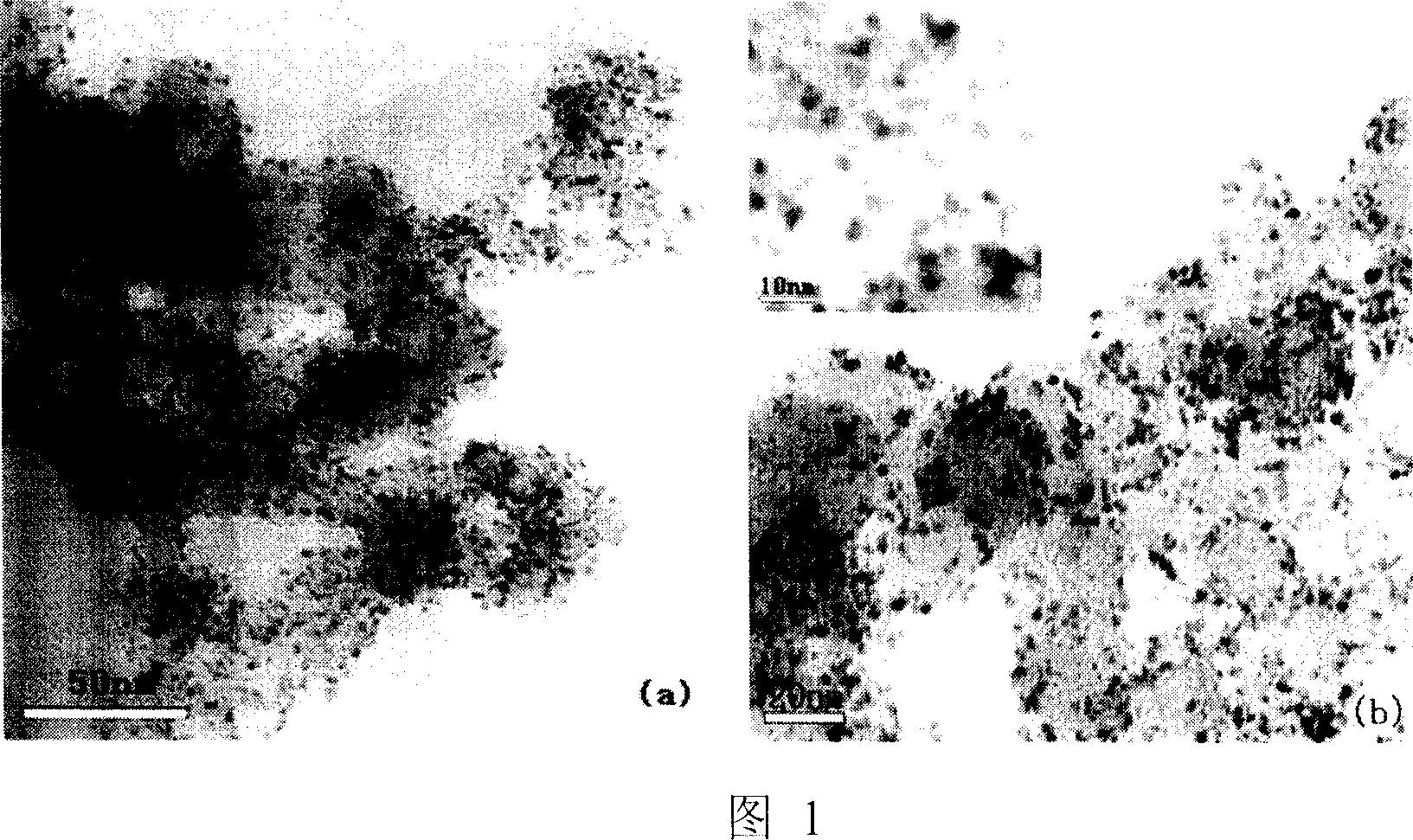

Embodiment 1

[0037] (1) H 2 PtCl 6 ·6H 2 O, sodium citrate and Xc-72R carbon black are added together in the mixed solution of ethylene glycol and propylene glycol, the volume ratio of ethylene glycol and propylene glycol is 1:5; Ultrasound at room temperature for 10 minutes. H in the mixed solution 2 PtCl 6 ·6H 2 The mass volume concentration of O is 7g / L; the mass volume concentration of sodium citrate is 5g / L; the mass volume concentration of Xc-72R carbon black suspension is 10g / L.

[0038] (2) To the mixed solution obtained in step (1), add an ethylene glycol solution with a mass concentration of 10% KOH, adjust the pH to 8, and react under normal pressure with nitrogen protection for 4 hours, and the temperature is controlled at 120°C.

[0039] (3) cooling the mixed solution obtained in step (2) to room temperature, adding mass concentration is 10% HNO 3 aqueous solution, adjust the pH value to 1, and ultrasonically vibrate for 10 minutes.

[0040] (4) The mixed solution obtai...

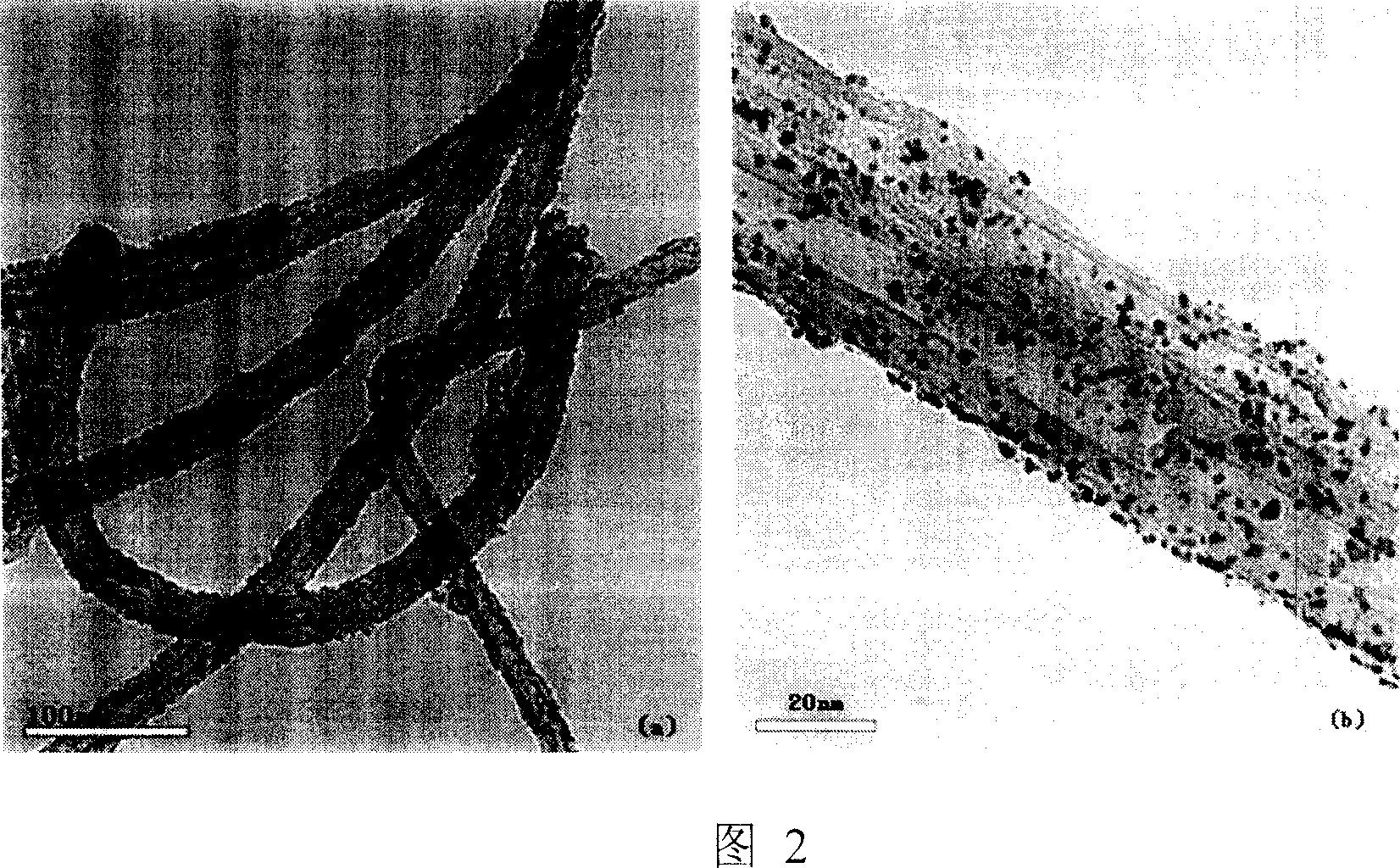

Embodiment 2

[0044] (1) PdCl 2 , disodium edetate, and Xc-72R carbon black are added together to the alcohol reducing agent ethylene glycol and the solvent is a mixed solution of butanediol and water, and the volume ratio of butanediol to water in the solvent is 4: 1; Sonicate at room temperature for 30 minutes, mix PdCl in the solution 2 The mass volume concentration is 5g / L; the mass volume concentration of disodium edetate is 10g / L; the mass volume concentration of Xc-72R carbon black suspension is 10g / L; the volume ratio of reducing agent ethylene glycol to solvent is 1 : 3.

[0045] (2) Adding a butanediol solution of 10% KOH in mass concentration to the mixed solution obtained in step (1), adjusting the pH to 10, reacting in an autoclave for 3 hours, the temperature is controlled at 140° C.

[0046] (3) cooling the mixed solution obtained in step (2) to room temperature, adding mass concentration is 10% HNO 3 aqueous solution, adjust the pH value to 3, and ultrasonically vibrate f...

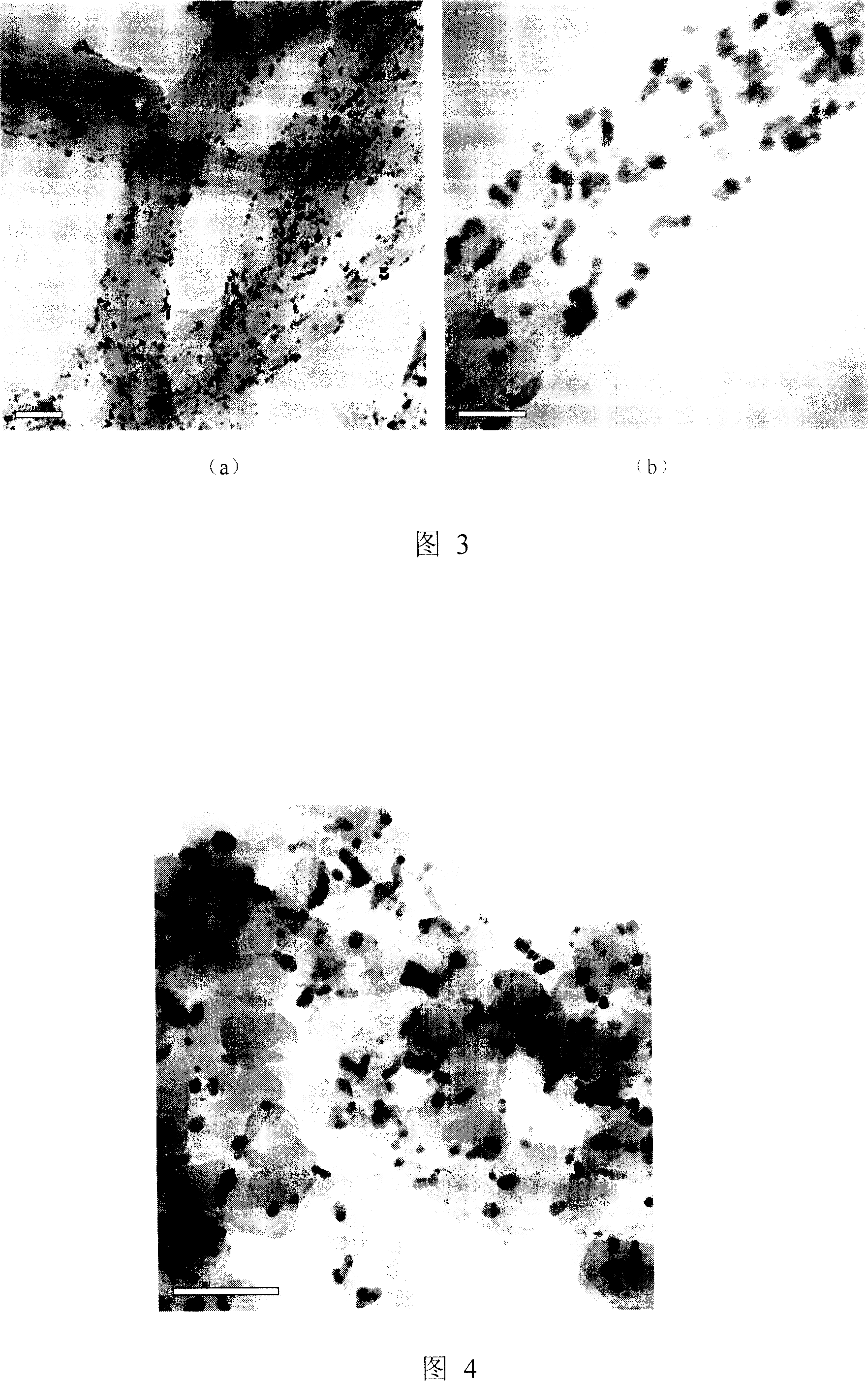

Embodiment 3

[0051] (1) RuCl 3 ·3H 2 O, sodium oxalate, and Xc-72R carbon black are added together to the mixed solution of propylene glycol and butanediol, the volume ratio of propylene glycol to butanediol is 1:1; ultrasonication at room temperature for 60 minutes, RuCl in the mixed solution 3 ·3H 2 The mass volume concentration of O is 1g / L; the mass volume concentration of sodium oxalate is 40g / L; the mass volume concentration of Xc-72R carbon black suspension is 4g / L.

[0052] (2) To the mixed solution obtained in step (1), add a propylene glycol solution with a mass concentration of 10% KOH to adjust the pH to 12, and react under normal pressure with nitrogen protection for 6 hours, and the temperature is controlled at 140° C.

[0053] (3) cooling the mixed solution obtained in step (2) to room temperature, adding mass concentration is 10% HNO 3 aqueous solution, adjust the pH value to 4, and ultrasonically vibrate for 30 minutes.

[0054] (4) The mixed solution obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com