Metal hydride hydrogen storage tank

A hydrogen storage tank and hydride technology, which is applied to fixed-capacity gas storage tanks, gas processing/storage purposes, gas/liquid distribution and storage, etc. Manufacturing and processing, simple structure, avoiding the effect of tank deformation and rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

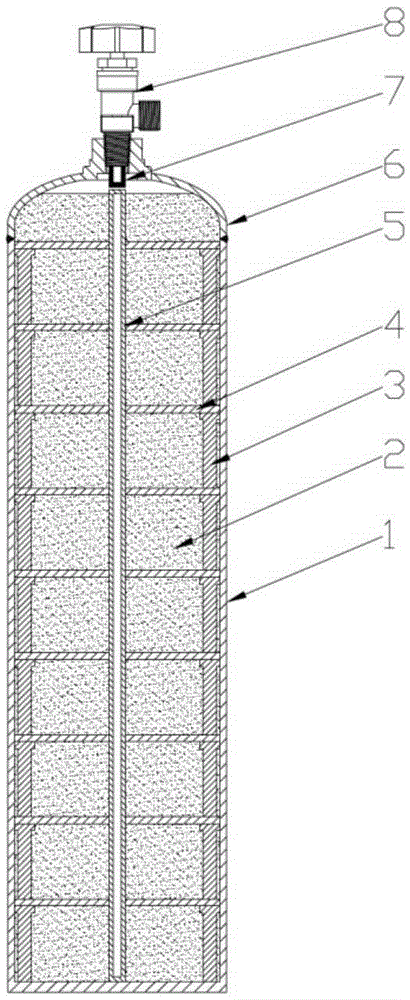

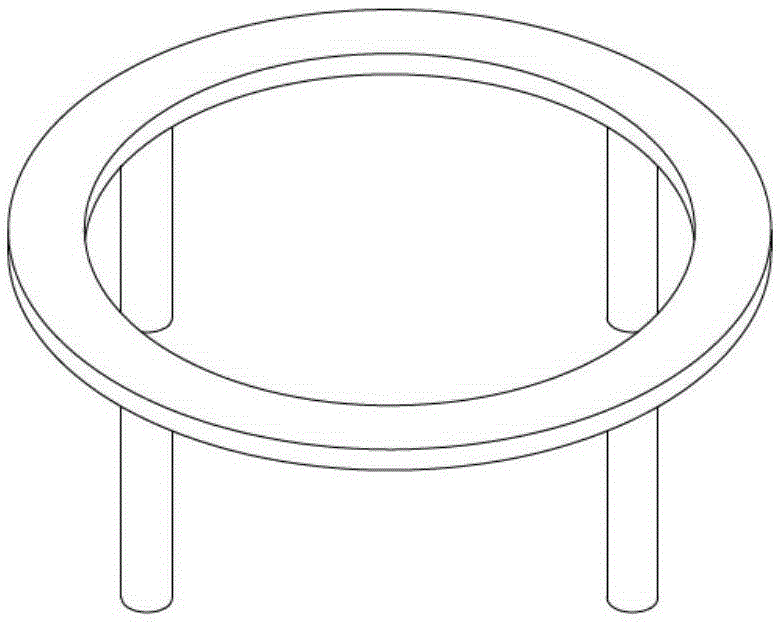

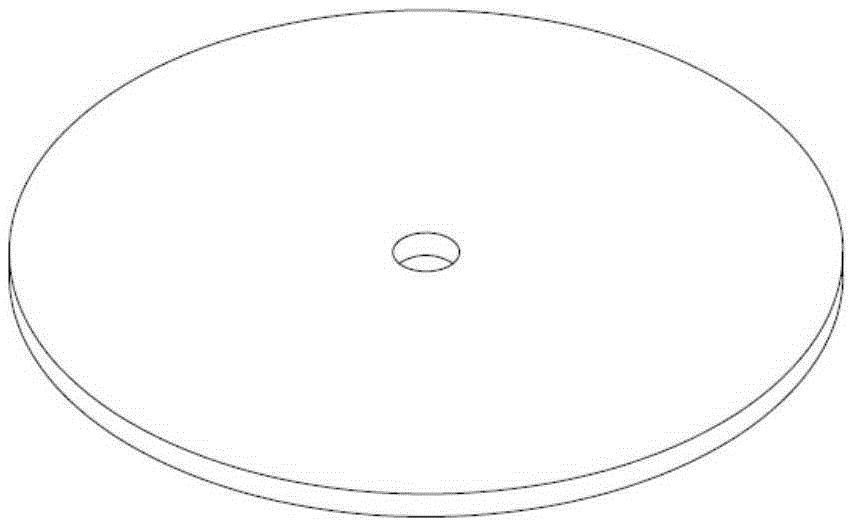

[0023] figure 1 It is a cross-sectional view of a metal hydride hydrogen storage tank. The metal hydride hydrogen storage tank is composed of a tank body 1, a hydrogen storage alloy 2, a support frame 3, a porous metal gas-conducting isolation plate 4, an air-conducting pipe 5, a head 6, a filter 7, and a valve 8.

[0024] The material of the metal hydride hydrogen storage tank body 1 is stainless steel, with an outer diameter of 133mm, an inner diameter of 125mm, a length of the straight part of 500mm, and a volume of 6.3L.

[0025] The hydrogen storage alloy 2 filled in the metal hydride hydrogen storage tank is LaNi 5 The hydrogen storage alloy has a hydrogen release platform pressure of 0.15 MPa at room temperature, a weight hydrogen storage rate of 1.5 wt%, and a total of 26 kg of hydrogen storage alloy.

[0026] An air guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com