A kind of processing method of nanometer and micrometer hole

A processing method, nanotechnology, applied in the direction of nanotechnology, technology for producing decorative surface effects, microstructure technology, etc., to achieve the effect of controllable shape and depth, environmentally friendly operation, and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

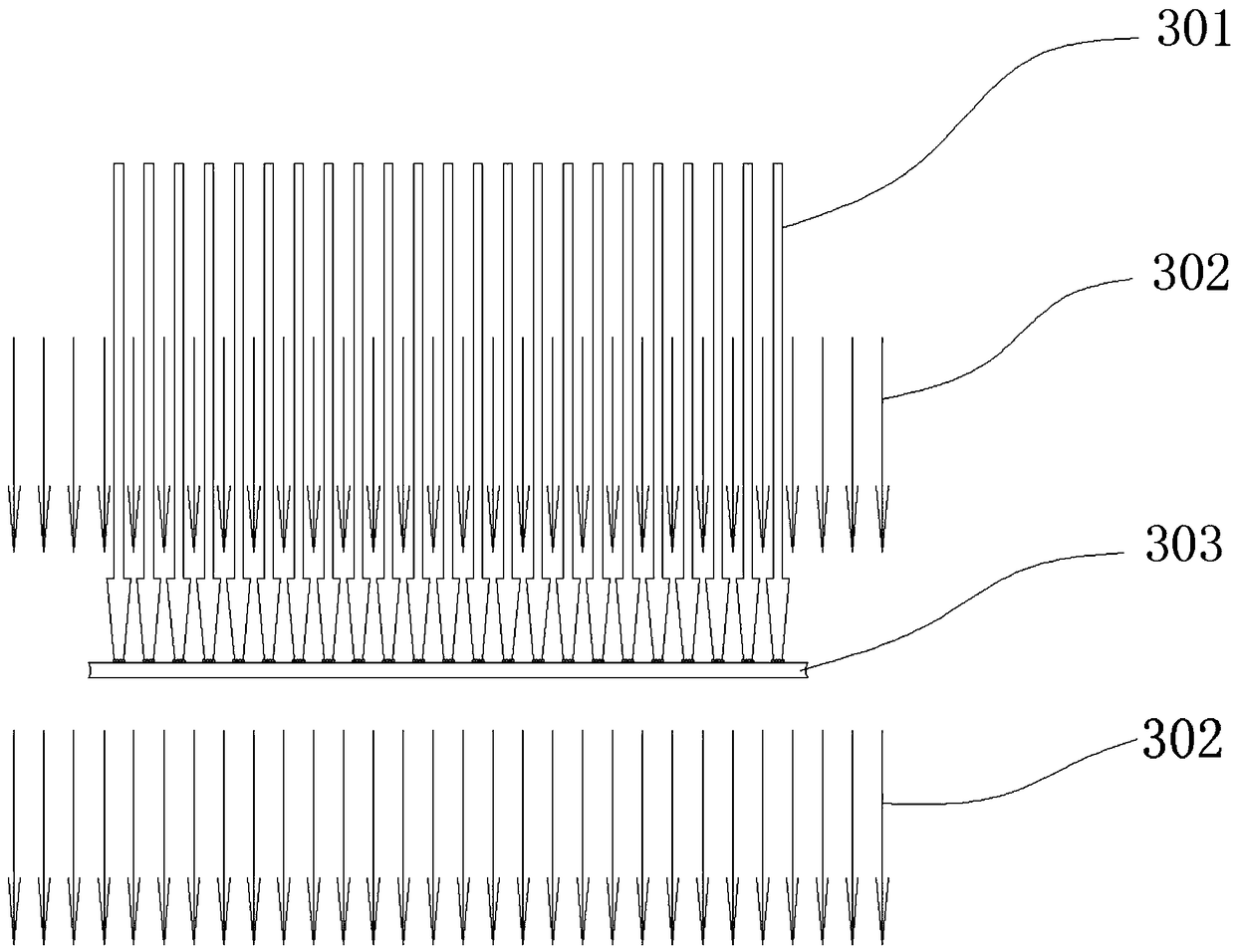

[0035] Step 1: Clean the substrate 101 with deionized water, and remove the surface dirt with a plasma cleaner; the substrate 101 is a plate-shaped material of polyethylene terephthalate (PET);

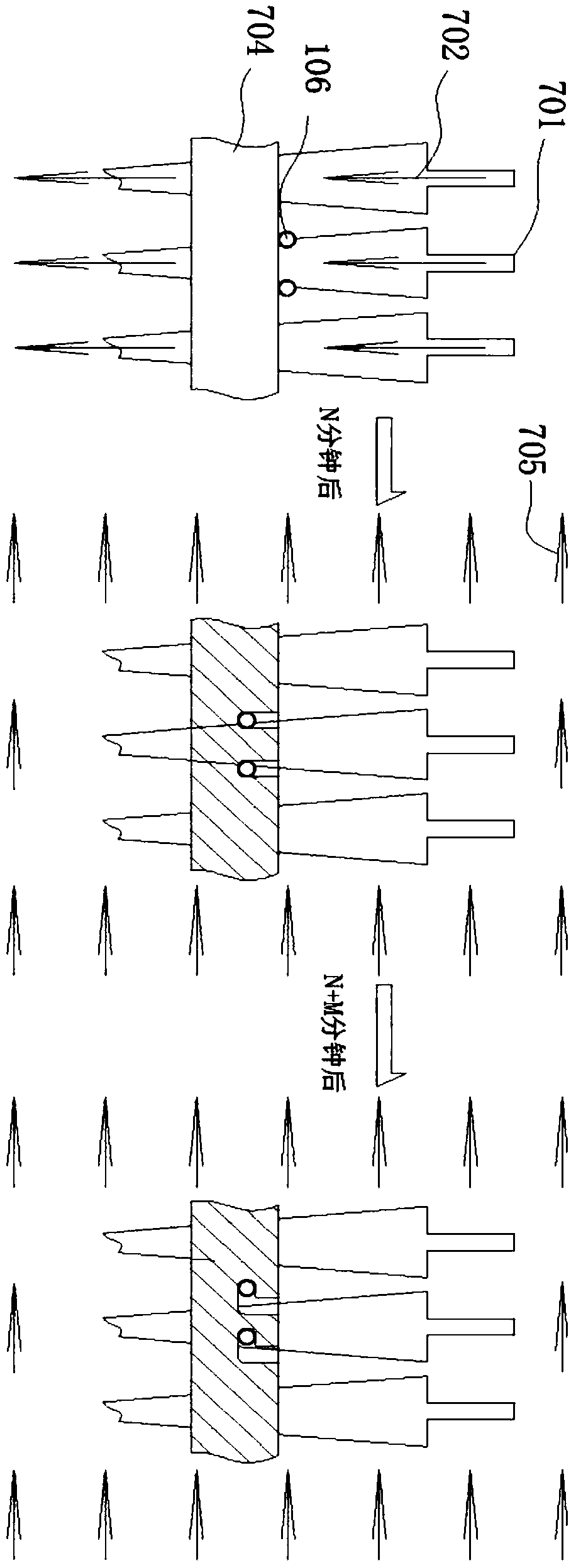

[0036] Step 2: If figure 1As shown, the photoresist 102 is spin-coated on the substrate 101, exposed and developed to form a specific substrate 103 printed with a target pattern;

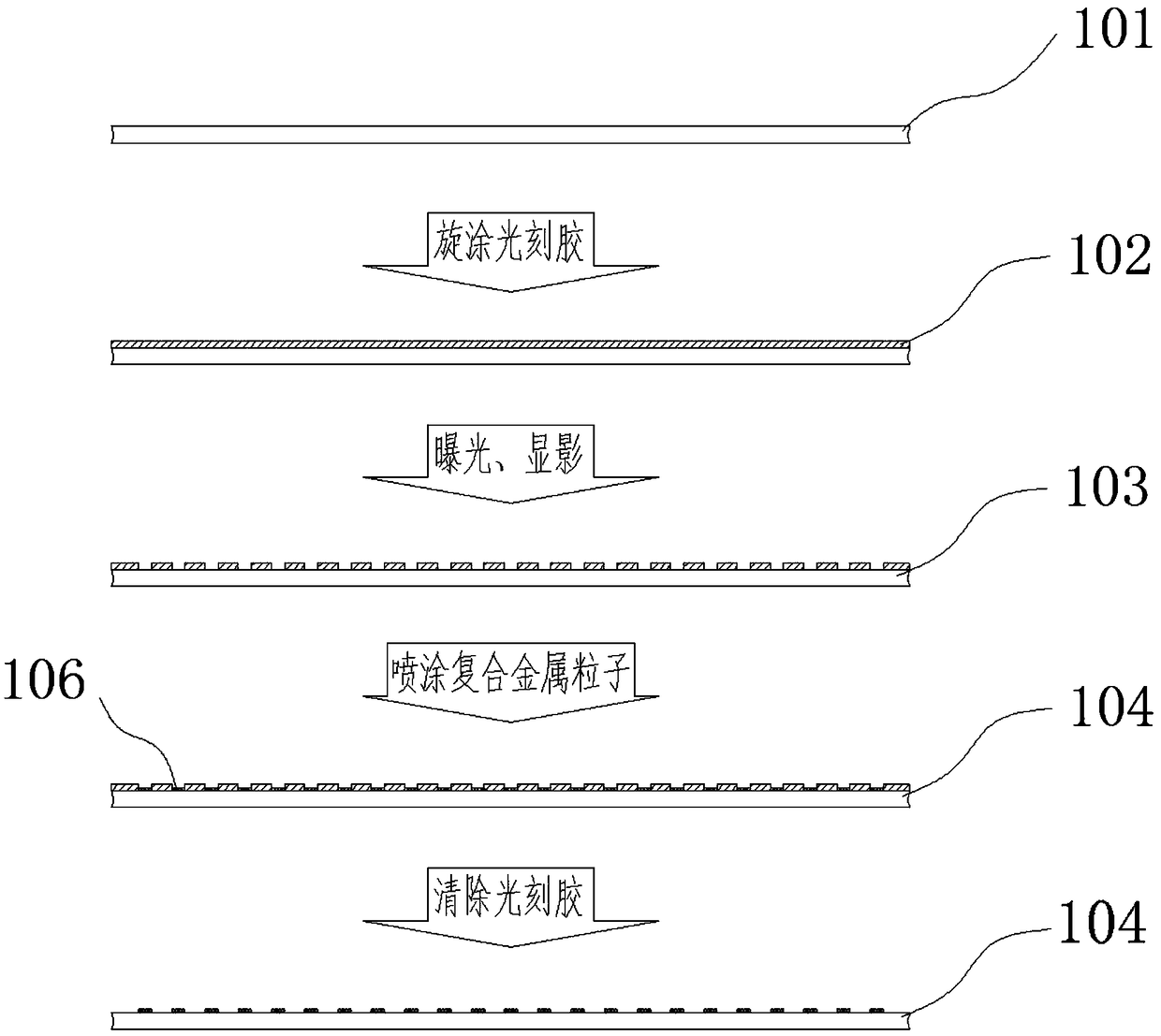

[0037] Step 3: Deposit micro-nano composite structure metal particles 106 on the substrate surface, that is, control the area of the micro-nano composite structure metal particles 106 deposited on the substrate surface according to the exposed pattern, and then control the shape of the nanopore or micropore (such as a circle shape, square, etc.) and aperture; the micro-nano composite metal particle 106 is centered on the magnetic core, and the surface of the magnetic core is coated with a nano-metal particle coating composed of a plurality of nano-gold, silver or aluminum particles; the magnetic The inne...

Embodiment 2

[0042] Step 1: Clean the substrate 101 with deionized water, and remove the surface dirt with a plasma cleaner; the substrate 101 is a glass plate material;

[0043] Step 2: Spin-coat the photoresist 102 on the substrate 101, expose and develop, and form a specific substrate 103 printed with target patterns;

[0044] Step 3: Deposit micro-nano composite structure metal particles 106 on the substrate surface, that is, control the area of the micro-nano composite structure metal particles 106 deposited on the substrate surface according to the exposed pattern, and then control the shape of the nanopore or micropore (such as a circle shape, square, etc.) and aperture; the micro-nano composite metal particle 106 is centered on the magnetic core, and the surface of the magnetic core is coated with a nano-metal particle coating composed of a plurality of nano-gold, silver or aluminum particles; the magnetic The inner core is any one of spherical iron particles, iron compound parti...

Embodiment 3

[0049] Step 1: Clean the substrate 101 with deionized water, and remove the surface dirt with a plasma cleaner; the substrate 101 is a glass plate material;

[0050] Step 2: Spin-coat the photoresist 102 on the substrate 101, expose and develop, and form a specific substrate 103 printed with target patterns;

[0051] Step 3: Deposit micro-nano composite structure metal particles 106 on the substrate surface, that is, control the area of the micro-nano composite structure metal particles 106 deposited on the substrate surface according to the exposed pattern, and then control the shape of the nanopore or micropore (such as a circle shape, square, etc.) and aperture; the micro-nano composite metal particle 106 is centered on the magnetic core, and the surface of the magnetic core is coated with a nano-metal particle coating composed of a plurality of nano-gold, silver or aluminum particles; the magnetic The inner core is any one of spherical iron particles, iron compound parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com