Nanowire self-reinforced porous silicon nitride ceramic and preparation method thereof

A silicon nitride ceramic and nanowire technology, which is applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of uneven pore size of porous silicon nitride ceramics, reducing the utilization rate of silicon powder, and uneven pore distribution. , to achieve the effect of uniform pore size, increased nitrogen concentration, and promotion of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

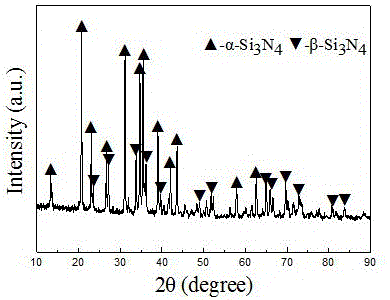

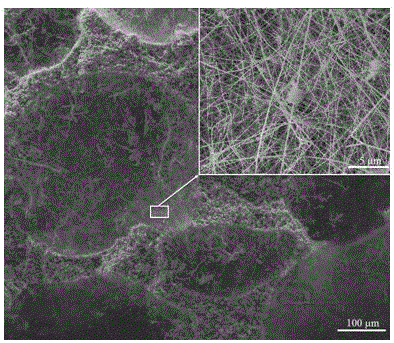

[0028] A nanowire self-reinforced porous silicon nitride ceramic and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0029] Step 1. Using 70-76wt% silicon powder, 5-10wt% catalyst and 14-20wt% nitrogen source as raw materials, add 20-26wt% deionized water of the raw materials, and stir for 30-60min to obtain a ceramic slurry material.

[0030] Step 2. Add foam made of 10-16wt% of the raw material foaming agent to the ceramic slurry under stirring conditions. After adding the foam, continue stirring for 30-60 minutes to obtain a ceramic foam slurry; The mass ratio of foaming agent and deionized water in the foam is 1: (10-13).

[0031] Step 3: Pour the ceramic foam slurry into a mould, let it stand at room temperature and in a nitrogen environment for 1-24 hours; then dry it at 60-110° C. for 12-24 hours, and demould to obtain a ceramic body.

[0032] Step 4: Place the ceramic green body in a vacuum tube furnace. Under th...

Embodiment 2

[0038] A nanowire self-reinforced porous silicon nitride ceramic and a preparation method thereof. The present embodiment is the same as embodiment 1 except blowing agent.

[0039] The blowing agent described in this embodiment is a mixture of alkylphenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether.

[0040] The nanowire self-reinforced porous silicon nitride ceramic prepared in this example is tested: the flexural strength is 20-26 MPa; the compressive strength is 50-60 MPa.

Embodiment 3

[0042] A nanowire self-reinforced porous silicon nitride ceramic and a preparation method thereof. The present embodiment is the same as embodiment 1 except blowing agent.

[0043] The foaming agent described in this embodiment is a mixture of fatty alcohol polyoxyethylene ether, sodium hydroxymethylcellulose and hydroxyethylcellulose.

[0044] The nanowire self-reinforced porous silicon nitride ceramic prepared in this example is tested: the flexural strength is 20-26 MPa; the compressive strength is 50-60 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com