Low-thermal-conductivity aerated concrete and preparation method thereof

A technology of air-entrained concrete and low thermal conductivity, which is applied in the fields of material science and engineering science, can solve the problems of insufficient strength of filling materials, low strength, and failure to meet energy-saving requirements, and achieve thermal insulation performance and mechanical properties. High water-reducing rate , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

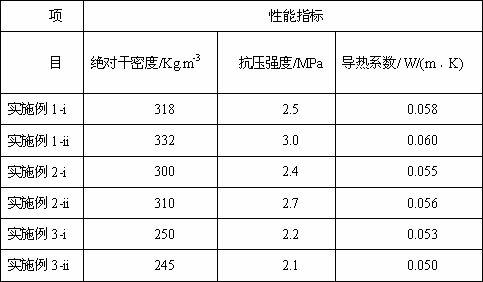

Embodiment 1

[0028] Embodiment 1: the present invention is used for making low thermal conductivity aerated concrete block

[0029] 1-i

[0030] (1) Take the following proportions of each raw material component (by weight percentage) and stir evenly to obtain a high-strength silicate-based material slurry: 38% cement, 15% ground quartz powder, 15% lime, 2% gypsum, conventional humidification treatment The desulfurized high-calcium ash is 5%, water is 25%, and the particle size of the ground quartz powder is between 5-30μm.

[0031] (2) Take the following raw materials and mix them to prepare a composite gas-generating component: 0.8 parts of aluminum powder paste, 8.5 parts of modified rosin air-entraining agent, 1.5 parts of protein foam stabilizer, and 0.2 parts of Si-C polyurethane foam stabilizer , 6 parts of hyperdispersant.

[0032] (3) Mix and stir the composite gas-generating component and high-strength silicate-based material slurry according to the following ratio (by weight pe...

Embodiment 2

[0039] Embodiment 2: The present invention is used to make low thermal conductivity aerated concrete roof panels

[0040] 2-i

[0041](1) Take the following proportions of each raw material component (by weight percentage) and stir evenly to obtain a high-strength silicate-based material slurry: 24% cement, 15% ground quartz powder, 15% lime, 1% gypsum, activated coal gangue 20%, water 25%, the particle size of ground quartz powder is between 5-30μm.

[0042] (2) Take the following raw materials and mix them to prepare a composite gas-generating component: 1 part of aluminum powder paste, 8.5 parts of modified rosin air-entraining agent, 1 part of protein foam stabilizer, and 0.2 part of Si-C polyurethane foam stabilizer , 6.5 parts of hyperdispersant.

[0043] (3) Mix and stir the composite gas-generating component and the high-strength silicate-based material slurry according to the following ratio (by weight percentage): 96% of the high-strength silicate-based material sl...

Embodiment 3

[0050] Embodiment 3: The present invention is used to make low thermal conductivity aerated concrete balcony railing

[0051] 3-i

[0052] (1) Take the following proportions of each raw material component (by weight percentage) and stir evenly to obtain a high-strength silicate-based material slurry: 33% cement, 12% ground quartz powder, 11% lime, 2% gypsum, MK series activity 12% metakaolin, 30% water, and the particle size of ground quartz powder is between 5-30μm.

[0053] (2) Take the following raw materials and mix them to prepare a composite gas-generating component: 1 part of aluminum powder paste, 9.5 parts of modified rosin air-entraining agent, 3 parts of protein foam stabilizer, and 0.2 part of Si-C polyurethane foam stabilizer , 8 parts of hyperdispersant.

[0054] (3) Mix and stir the composite gas-generating component and the high-strength silicate-based material slurry according to the following ratio (by weight percentage): 95% of the high-strength silicate-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com