Metal/carbon nano composite porous membrane and preparation method thereof

A carbon nanocomposite, porous membrane technology, applied in the field of porous membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

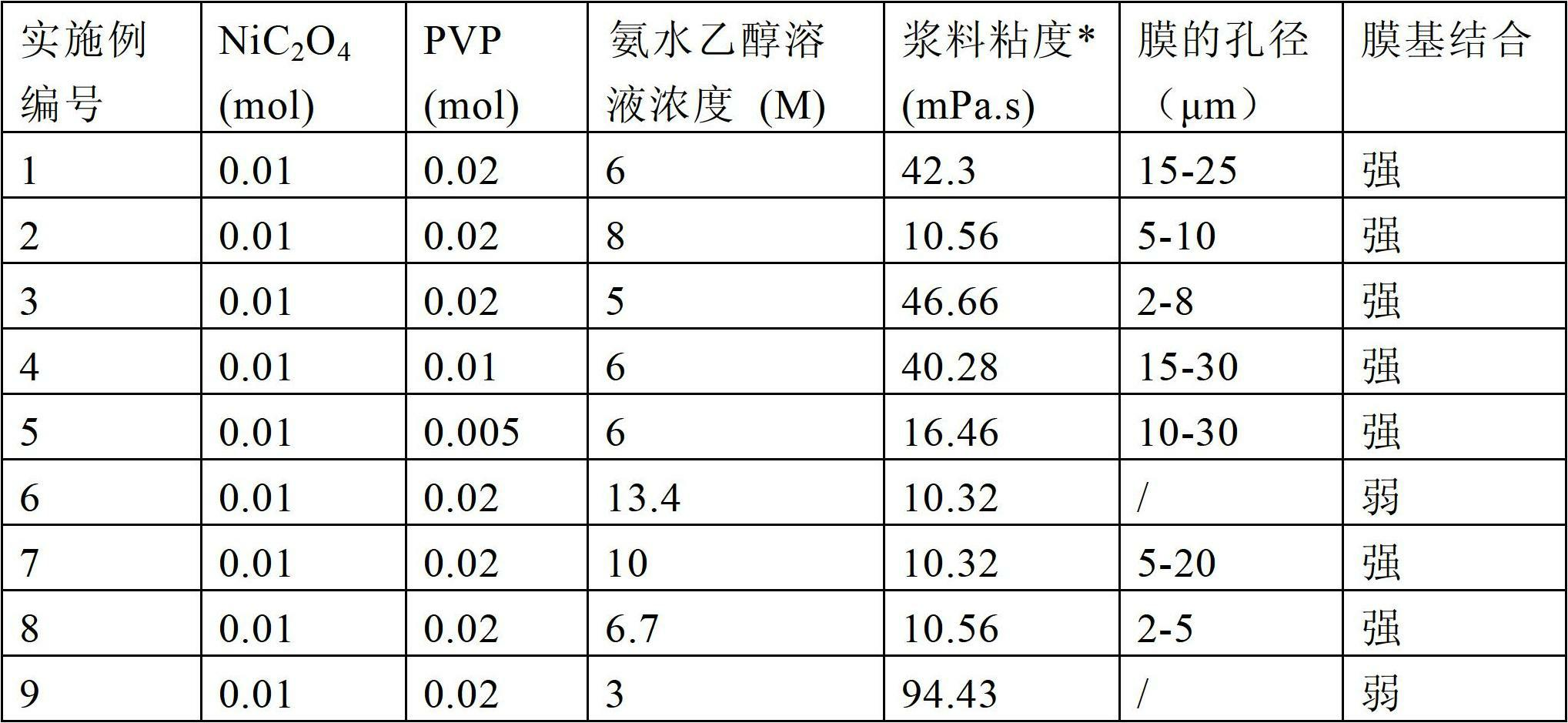

[0052] Add 0.01mol nickel oxalate dihydrate and 0.02mol PVP into 6mol / L ammonia water ethanol solution, and keep stirring at room temperature to obtain a uniform blue sol. The sol is continuously stirred to make the sol pregelatinize into a slurry with a certain viscosity. Drop the slurry onto the cleaned alumina surface and dry until the solvent evaporates completely. The sample obtained after drying was heat-treated under the protection of an inert atmosphere at 550° C. for 2 hours to form a porous nickel-carbon film.

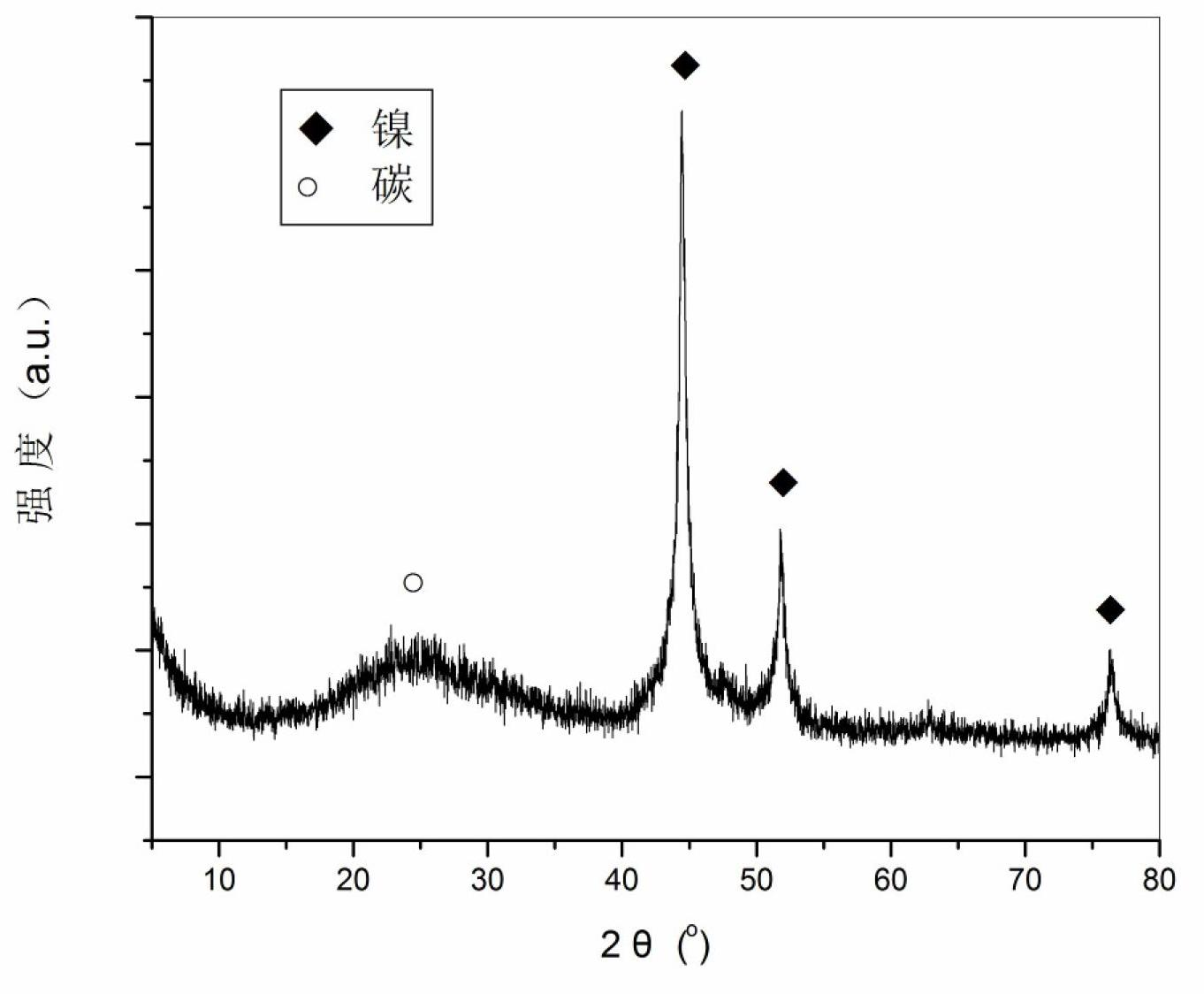

[0053] figure 1 It is the X-ray diffraction spectrum of the porous nickel carbon film in this example. figure 1 The three sharp diffraction peaks (44.5°, 51.8° and 76.4°) indicated by the solid diamonds in the center correspond to metallic nickel (Standard Card Library No.: 04-0850), and the one broad peak indicated by the open circles corresponds to graphitic carbon (Standard Card library number: 41-1487).

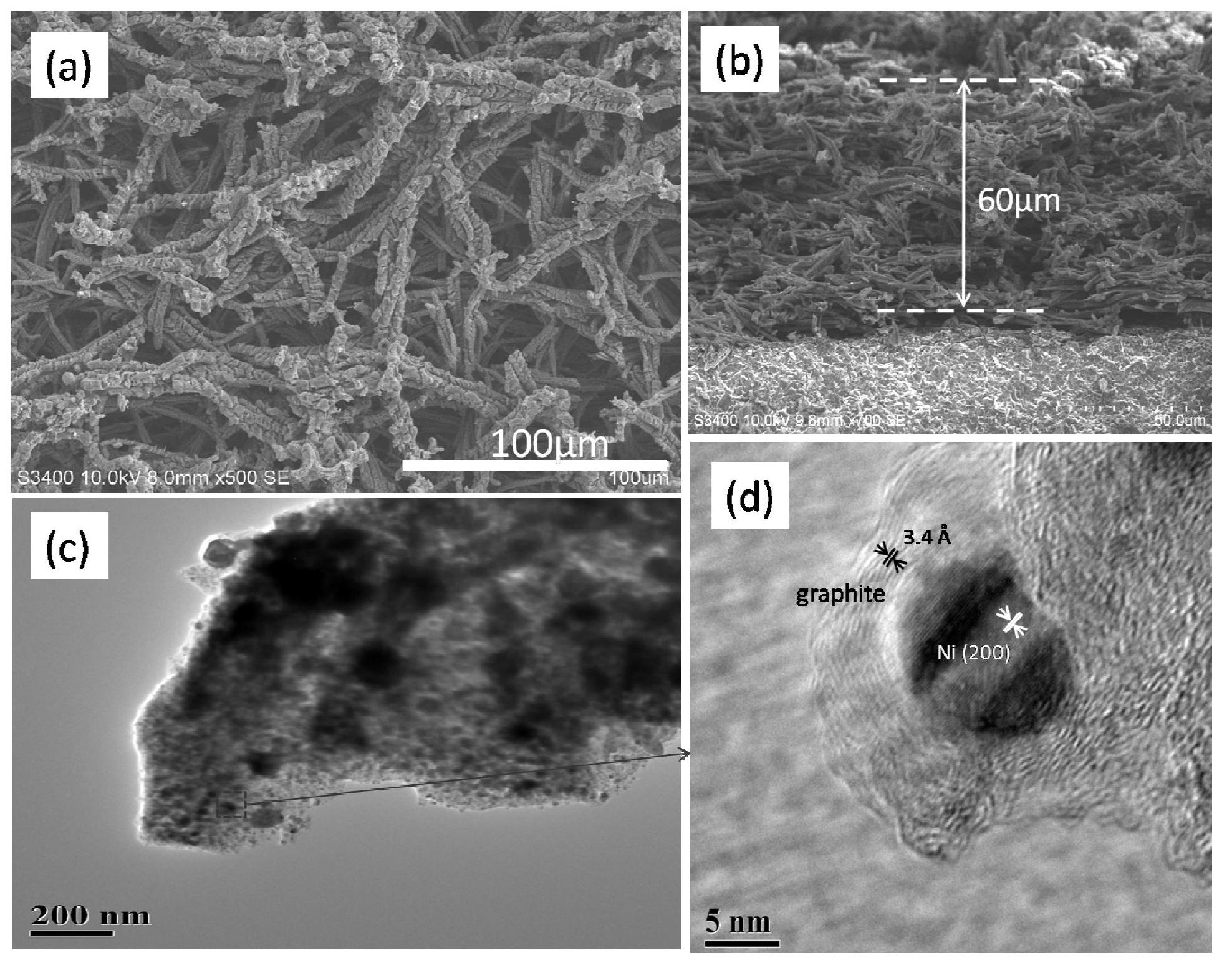

[0054] figure 2 It is a scanning electron mi...

Embodiment 2

[0057] Add 0.01mol nickel oxalate dihydrate and 0.02mol PVP into 8mol / L ammonia water ethanol solution, and keep stirring at room temperature to obtain a uniform blue sol. The sol is continuously stirred to make the sol pregelatinize into a slurry with a certain viscosity.

[0058] All the other contents are the same as those described in Example 1.

[0059] The membrane-substrate bonding degree and pore size distribution of the porous nickel-carbon membrane obtained in this example are shown in Table 1 below.

[0060] It can be seen from the data in Table 1 that the porous membrane has a strong bond with alumina, but the average pore size is smaller than that of Example 1.

Embodiment 3

[0062] Add 0.01mol nickel oxalate dihydrate and 0.02mol PVP into 5mol / L ammonia water ethanol solution, and keep stirring at room temperature to obtain a uniform blue sol. The sol is continuously stirred to make the sol pregelatinize into a slurry with a certain viscosity.

[0063] All the other contents are the same as those described in Example 1.

[0064] The membrane-substrate bonding degree and pore size distribution of the porous nickel-carbon membrane obtained in this example are shown in Table 1 below.

[0065] It can be seen from the data in Table 1 that the porous membrane has a strong bond with alumina, but the average pore size is also smaller than that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com