Coating slurry for bonding lithium battery separator and pole piece and preparation method of coating slurry

A lithium battery separator and battery separator technology, which is applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as affecting the rate and cycle performance of lithium ion batteries, blocking the pores of the coating substrate, and reducing ionic conductivity. Achieve the effect of avoiding the influence of the battery rate and cycle performance, the cycle performance is not affected, and the ionic conductivity is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 50ml round bottom flask, add 0.1g of ammonium bicarbonate, then add 20ml of deionized water, and form a clear and transparent solution under stirring conditions; add 1g of alumina ceramic dry powder particles in another flask, and then add 100ml of deionized water Ionized water was used for dispersion; the third flask took 0.5g of polyvinylidene fluoride PVDF binder, which was stirred and dispersed in 50ml of organic solvent NMP; after the three were uniformly dispersed, the clear and transparent ammonium bicarbonate solution, The dispersed PVDF glue is added to the flask containing alumina, and the coating slurry is made after the three are fully mixed. Then, the coating slurry is coated on the diaphragm substrate and connected to the pole piece, and then dried at 80° C., so that the diaphragm and the pole piece can be connected, and uniformly distributed pores are formed in the coating.

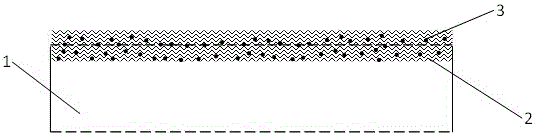

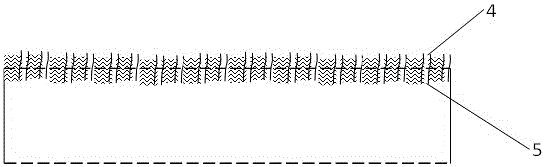

[0033] Such as figure 1 As shown, the coating slurry is coated on the diap...

Embodiment 2

[0035] In a 50ml round bottom flask, add 0.1g of ammonium carbonate, then add 20ml of deionized water, and form a clear and transparent solution under stirring conditions; add 1g of boehmite dry powder particles to another flask, and then add 100ml of deionized Disperse with water; take 0.5g of carboxymethylcellulose CMC binder in the third flask, stir and disperse it in 50ml deionized water; The good CMC glue is added to the flask containing boehmite, and the coating slurry is made after the three are fully mixed. Then, the coating slurry is coated on the diaphragm substrate and connected to the pole piece, and then dried at 80° C., so that the diaphragm and the pole piece can be connected, and uniformly distributed pores are formed in the coating.

Embodiment 3

[0037] In a 150ml round bottom flask, add 0.1g of ammonium bicarbonate, then add 120ml of deionized water, and form a clear and transparent solution under stirring conditions; add 1g of silica dry powder particles to another flask, and then add 100ml of deionized Water to disperse; take 0.5g polyacrylic acid PAA from the third flask, stir and disperse it in 50ml deionized water; after the three are evenly dispersed, add the clear and transparent ammonium bicarbonate solution and dispersed PAA glue Stir in a flask filled with silicon dioxide, and make a coating slurry after the three are stirred until they are evenly dispersed. Then, the coating slurry is coated on the substrate of the positive electrode plate and bonded to the separator, and then dried at 80° C., so that the connection between the separator and the positive electrode sheet can be realized, and uniformly distributed pores can be formed in the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com