Porous ceramic-based grinding block for grinding semiconductor plastic package substrate and manufacturing method of porous ceramic-based grinding block

A technology of porous ceramics and manufacturing methods, which is applied in the direction of ceramic products, manufacturing tools, abrasives, etc., and can solve problems such as adverse effects on product stability, gas generation, micro-cracks and deformation of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

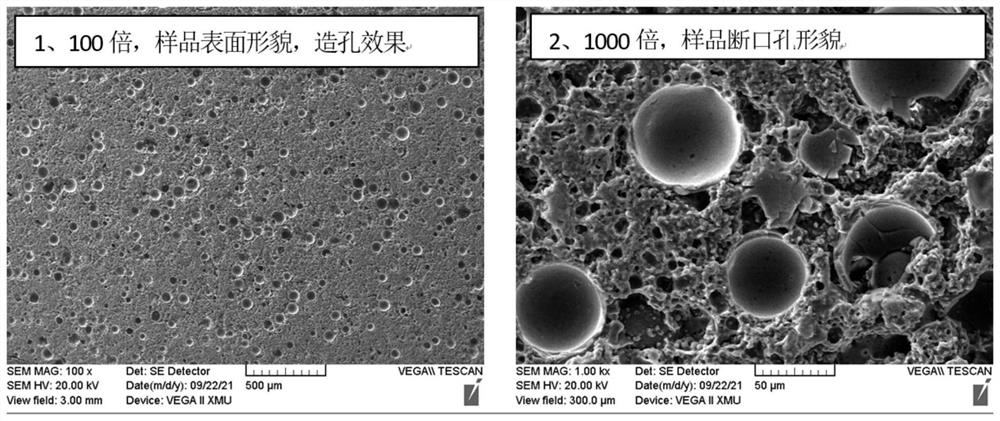

Image

Examples

Embodiment 1

[0030] The manufacturing method of the porous ceramic-based grinding block for grinding semiconductor plastic-encapsulated substrates of the present invention comprises the following steps:

[0031] 1) Drying: Place the required ceramic bond, diamond powder, aluminum ball pore-forming agent and other raw materials in a drying oven, set the temperature at 300°C, and hold for 1 hour;

[0032] 2) Screening: Before screening, clean the screen with an ultrasonic cleaner for 30 minutes, and wash once. The screen model is two standard grades larger than the selected diamond size, and the diamond powder is passed through a vibrating screen. Sieve, sieve 3 times to ensure the removal of large diamond particles in the diamond raw material;

[0033] 3) Ingredients: Weigh 35% vitrified bond, 35% diamond, 20% aluminum ball pore-forming agent, and 10% auxiliary agent with an electronic balance according to mass percentage. The particle size of the aluminum ball pore-forming agent is 30-100...

Embodiment 2

[0040] The manufacturing method of the porous ceramic-based grinding block for grinding semiconductor plastic-encapsulated substrates of the present invention comprises the following steps:

[0041] 1) Drying: Place the required vitrified bond, diamond powder, aluminum ball pore-forming agent and other raw materials in a drying oven, set the temperature at 50°C, and hold for 5 hours;

[0042] 2) Screening: Before screening, clean the screen with an ultrasonic cleaner for 30 minutes, and wash once. The screen model is two standard grades larger than the selected diamond size, and the diamond powder is passed through a vibrating screen. Sieve, sieve 3 times to ensure the removal of large diamond particles in the diamond raw material;

[0043]3) Ingredients: Weigh 50% vitrified bond, 35% diamond, 10% aluminum ball pore-forming agent, and 5% auxiliary agent with an electronic balance according to mass percentage. The particle size of the aluminum ball pore-forming agent is 30-100...

Embodiment 3

[0050] The manufacturing method of the porous ceramic-based grinding block for grinding semiconductor plastic-encapsulated substrates of the present invention comprises the following steps:

[0051] 1) Drying: Place the required vitrified bond, diamond powder, aluminum ball pore-forming agent and other raw materials in a drying oven, set the temperature at 250°C, and hold for 3 hours;

[0052] 2) Screening: Before screening, clean the screen with an ultrasonic cleaner for 30 minutes, and wash once. The screen model is two standard grades larger than the selected diamond size, and the diamond powder is passed through a vibrating screen. Sieve, sieve 3 times to ensure the removal of large diamond particles in the diamond raw material;

[0053] 3) Ingredients: Weigh 45% vitrified bond, 37% diamond, 12% aluminum ball pore-forming agent, and 6% auxiliary agent with an electronic balance according to mass percentage. The particle size of the aluminum ball pore-forming agent is 30-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com