3D network organic-inorganic hybrid all-solid-state electrolyte and lithium secondary battery

An electrolyte, all-solid-state technology, used in non-aqueous electrolyte batteries, secondary batteries, solid electrolytes, etc., can solve the problems of poor high-temperature mechanical properties and thermal stability, large thickness of electrolyte sheets, and high battery interface resistance, and achieve inhibition of lithium branching. effect of crystal growth, good flexibility and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

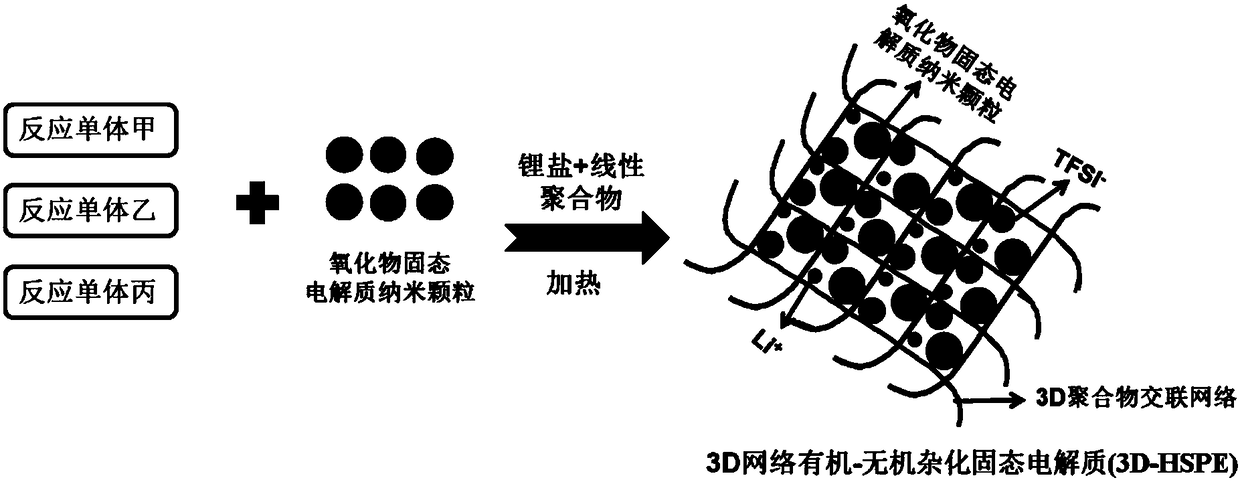

[0060] The present invention also provides a preparation method of the above-mentioned 3D network organic-inorganic hybrid all-solid-state electrolyte, comprising the following steps:

[0061] A) mixing linear polymer, lithium salt and solvent to obtain mixed solution;

[0062] B) mixing the reaction monomer with epoxy group, glycidyl ether type epoxy resin and its derivatives, crosslinking agent, oxide electrolyte nanoparticles and solvent to obtain a mixed dispersion;

[0063] C) mixing and stirring the mixed solution and the mixed dispersion to obtain a reaction precursor solution;

[0064] D) injecting the reaction precursor solution into the mold or coating the surface of the substrate, heating to react, and drying to obtain a 3D network organic-inorganic hybrid all-solid-state electrolyte;

[0065] Step A) and step B) are not limited in order.

[0066] Specifically, in the present invention, the solvent described in step A) and the solvent described in step B) are pref...

Embodiment 1

[0083] The present embodiment relates to a method for preparing a 3D network organic-inorganic hybrid solid-state electrolyte, and the method includes the following steps:

[0084] (1) Add 0.10g of polyethylene oxide (PEO, Mn=600000) to a 25ml beaker A, then add 2.0g of acetonitrile dropwise with a pipette, stir for 2h to dissolve it completely, then add 0.55g of LiTFSI and continue stirring Form a colorless and transparent solution;

[0085] (2) 0.10g polyethylene glycol diglycidyl ether (Mn=500), 0.06g bisphenol A diglycidyl ether epoxy resin E51 (epoxy value 186) and 0.4 g polyetheramine (Mn=2000) was added to the beaker, 2.0g of acetonitrile was added dropwise with a pipette, and finally 1.2g of LAGP nanoparticles (particle size: 300±10nm) were added, stirred for 6h and mixed well to form a white precursor mixture.

[0086] (3) Pour the solution in beaker A into beaker B, and after rapid stirring for 6 hours, a uniformly mixed reaction precursor mixture is obtained; the ...

Embodiment 2

[0098] The present embodiment relates to a preparation method of a PEO+lithium salt-based all-solid-state electrolyte reference sample, and the method includes the following steps:

[0099] (1) Add 0.72g of PEO (Mn=100000) into a 25ml beaker, then dropwise add 6.0g of acetonitrile, stir to dissolve completely, then weigh 0.59g of LiTFSI, stir for 6h and mix well. The above solution was poured into a clean polytetrafluoroethylene mold, and after standing for a period of time, it was placed in a vacuum oven for drying at a constant temperature of 60 ° C for 8 hours to obtain PEO+lithium salt-based all-solid-state electrolyte. The obtained PEO-based solid electrolyte membrane was Put it in the glove box for later use.

[0100] The thickness of the PEO+lithium salt-based all-solid-state electrolyte membrane prepared in this example is 180 μm, and the room temperature conductivity is 1.52×10 -5 S cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com