Epoxy resin compositions for fiber-reinforced composite materials, process for production of the materials and fiber-reinforced composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

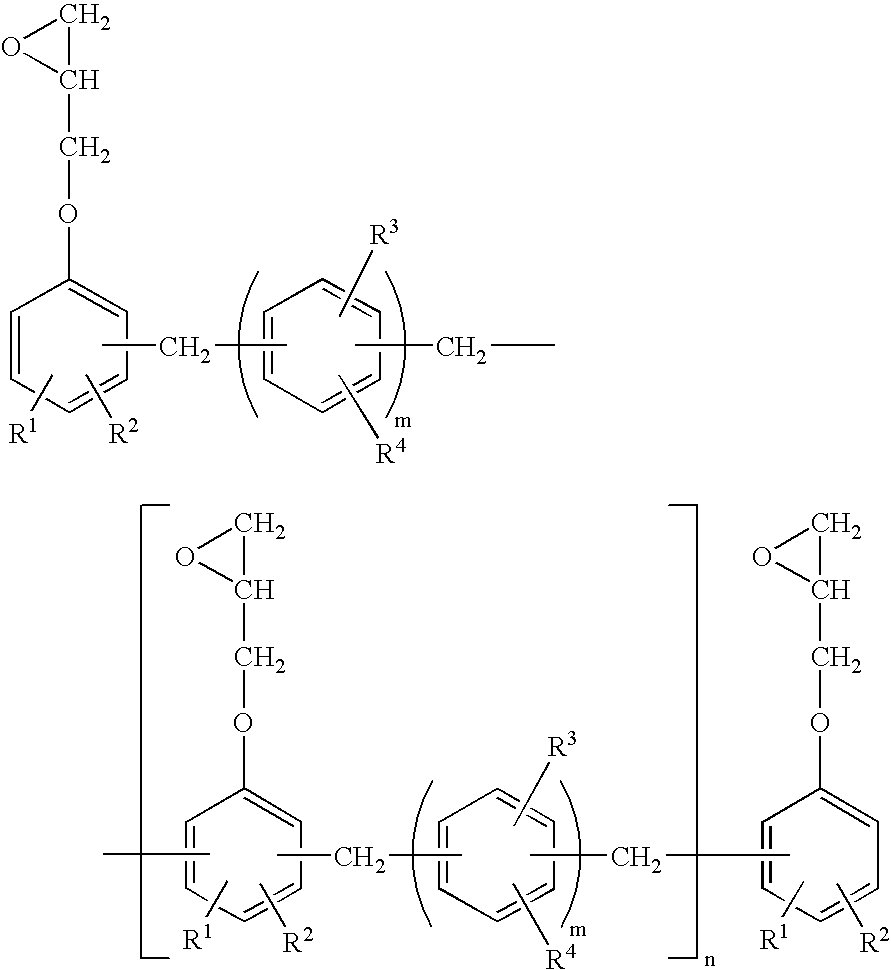

Method used

Image

Examples

example 1

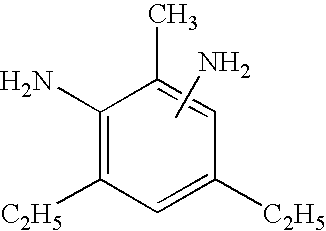

[0215] One hundred (100) parts of "Epikote" 630, selected as component (1), is used as Liquid (A1). Seventy (70) parts of "Epicure" W, selected as component (2), and 30 parts of 3,3'-DAS, selected as component (3), are mixed and stirred for one hour at 100.degree. C. until 3,3'-DAS is dissolved homogeneously to provide liquid (B1). No precipitation took place in Liquid (B1) when stored at 5.degree. C. for 30 days.

[0216] One hundred (100) parts of liquid (A1) and 50.3 parts of liquid (B1) were mixed to produce an epoxy resin composition, followed by measurement of its initial viscosity at 80.degree. C. and viscosity after storage for one hour, which were found to be 28 cP and 39 cP, respectively, showing that its viscosity was sufficiently low.

[0217] Then, cured resin plates were produced by the method described above and their properties were measured, with results indicating that their glass transition temperature after curing at 130.degree. C. for two hours and curing at 180.degre...

example 2

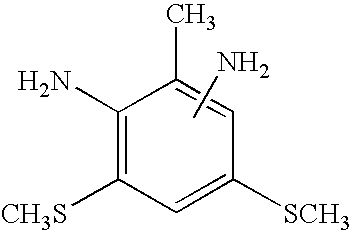

[0219] Liquid (A1) was prepared by the same procedure as in example 2. Seventy (70) parts of "Epicure" W, selected as component (2), 15 parts of 3,3'-DAS, selected as component (3), and 15 parts of "Sumicure" S were mixed and stirred for one hour at 100.degree. C. until 3,3'-DAS and "Sumicure" S were dissolved homogeneously to provide liquid (B1). No precipitation took place in Liquid (B1) when stored at 5.degree. C. for 30 days.

[0220] One hundred (100) parts of liquid (A1) and 50.3 parts of liquid (B1) were mixed to produce an epoxy resin composition, followed by measurement of its initial viscosity at 80.degree. C. and viscosity after storage for one hour, which were found to be 28 cP and 39 cP, respectively, showing that its viscosity was sufficiently low. Then, cured resin plates were produced by the method described above and their properties were measured, with results indicating that their glass transition temperature after curing at 130.degree. C. for two hours and curing at...

example 3

[0221] Liquid (A1) was prepared by the same procedure as in example 1. Further, 2 parts of PTSP, used as accelerator, was added to liquid (B1) prepared in example 2 to provide a new liquid (B1)

[0222] One hundred (100) parts of liquid (A1) and 51.3 parts of liquid (B1) were mixed to produce an epoxy resin composition, followed by measurement of its initial viscosity at 80.degree. C. and viscosity after storage at 80.degree. C. for one hour, which were found to be 24 cP and 79 cP, respectively, showing that its viscosity was sufficiently low. Then, cured resin plates were produced by the method described above and their properties were measured, with results indicating that their glass transition temperature after curing at 130.degree. C. for two hours and curing at 180.degree. C. for two hours was 128.degree. C. and 227.degree. C., respectively. The glass transition temperature after curing at 130.degree. C. for two hours was higher than in example 2 (109.degree. C.), showing that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com