VOC (Volatile Organic Compounds)-free water-based epoxy curing agent

A water-based epoxy and curing agent technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of complex preparation process of curing agent, short storage period of curing agent, difficult to control the reaction, etc., to achieve strong adhesion and corrosion resistance Excellent performance and fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

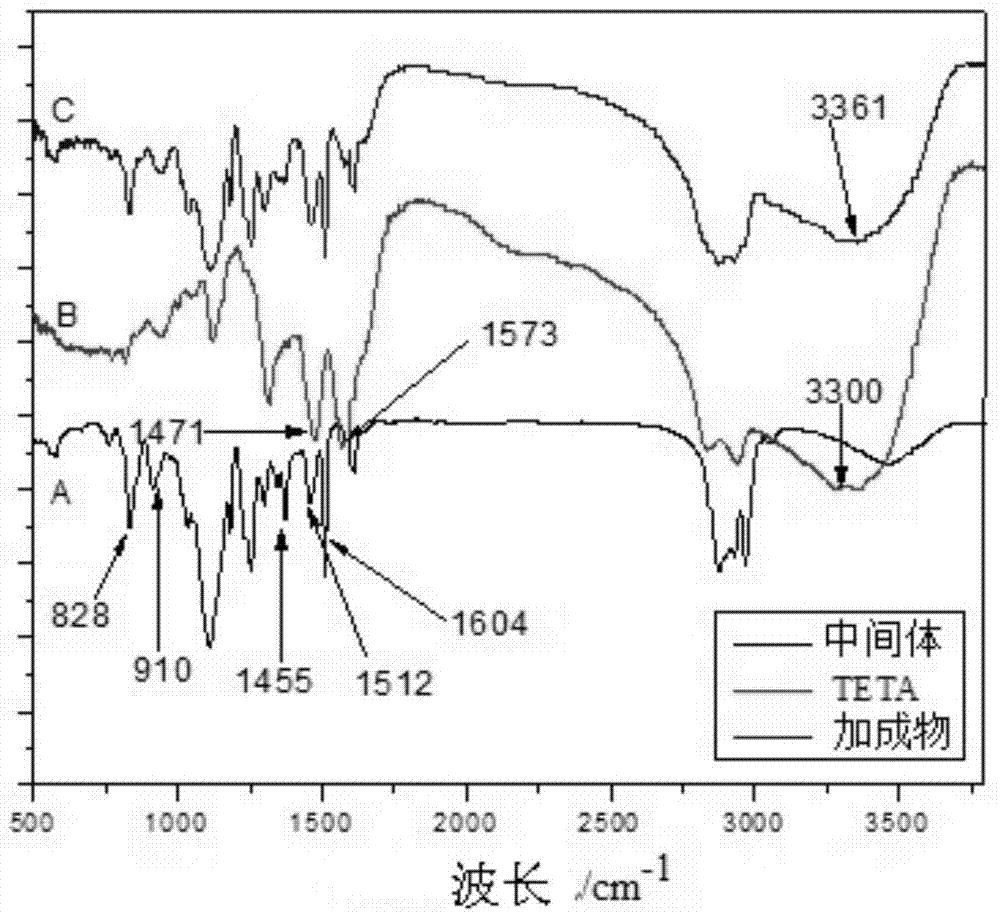

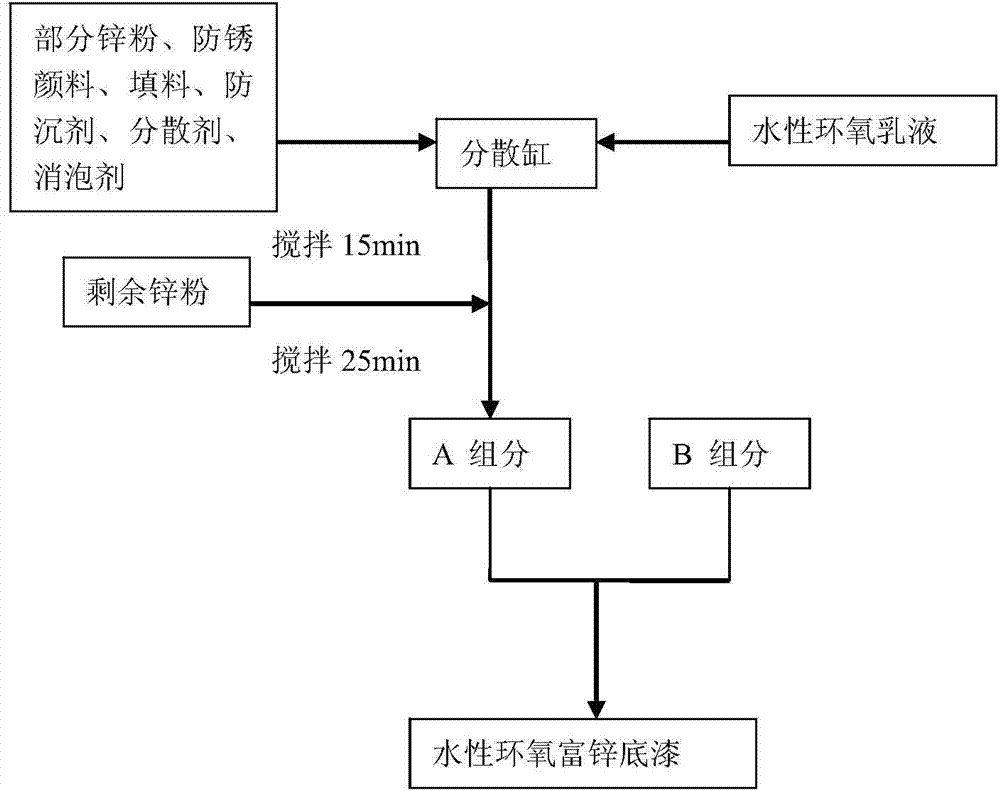

[0034] Embodiment 1: the preparation of waterborne epoxy resin curing agent 1

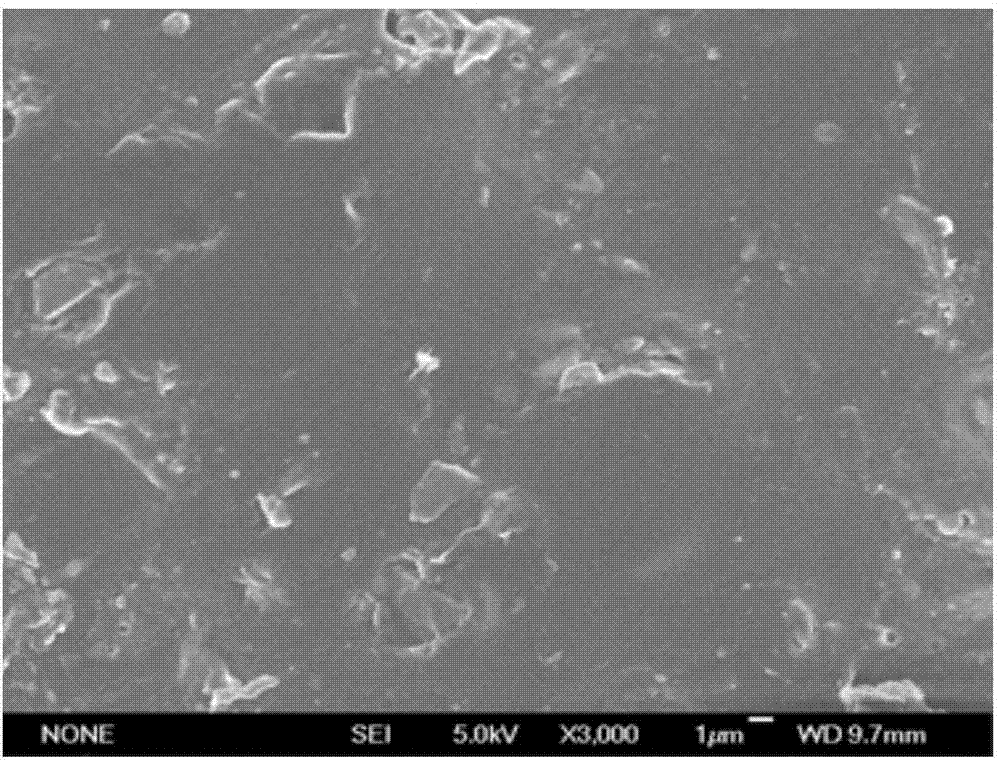

[0035] Add 51.6g CYD-115 and 116g polypropylene glycol diglycidyl ether in a 500ml four-neck flask in an oil bath device with a stirrer, thermocouple, condenser and constant pressure dropping funnel, and feed N 2While heating to 100°C, slowly add 20g of ED-600 dropwise. After the dropwise addition, heat to 150°C and keep it warm for about 4 hours until the amino reaction is complete. Finally, cool to room temperature to obtain a light yellow transparent intermediate with an epoxy value of 0.292mol / 100g . Then add 74.4g diethylenetriamine in the same device, while feeding N 2 While heating to 80°C, slowly add 170g of the intermediate dropwise. After the dropwise addition, keep it warm for about 4 hours until the epoxy group is completely reacted, and then distill under reduced pressure to remove the excess amine to obtain the adduct; In the dispersing cylinder, after passing circulating water at 9...

Embodiment 2

[0038] Embodiment 2: the preparation of waterborne epoxy resin curing agent 2

[0039] Add 39.2g CYD-127 and 78g polypropylene glycol diglycidyl ether in a 500ml four-necked flask in an oil bath device with a stirrer, thermocouple, condenser and constant pressure dropping funnel, and feed N 2 While heating to 110°C, slowly add 14g of ED-600 dropwise. After the dropwise addition, heat to 160°C and keep it warm for about 4 hours until the amino reaction is complete. Finally, cool to room temperature to obtain a light yellow transparent intermediate with an epoxy value of 0.289mol / 100g. Then add 51.6g triethylenetetramine in the same device, while feeding N 2 While heating to 80°C, slowly add 110g of the intermediate dropwise. After the dropwise addition, keep it warm for about 5 hours until the epoxy group reacts completely, and then distill under reduced pressure to remove the excess amine to obtain the adduct; In the dispersing cylinder, after passing circulating water at 8...

Embodiment 3

[0043] Embodiment 3: the preparation of waterborne epoxy resin curing agent 3

[0044] Add 57g CYD-115c and 116g polyethylene glycol diglycidyl ether in the 500ml four-neck flask in the oil bath device with stirrer, thermocouple, condenser and constant pressure dropping funnel, feed into N 2 While heating to 100°C, slowly add 19.8g of ED-900 dropwise. After the dropwise addition, heat to 150°C and keep warm for about 4 hours until the amino group reaction is complete. Finally, cool to room temperature to obtain a light yellow transparent intermediate. Then add 51.4g diethylenetriamine in the same device, while feeding N 2 While heating to 80°C, slowly add 80g of the intermediate dropwise. After the dropwise addition, keep it warm for about 5 hours until the epoxy group is completely reacted, and then distill under reduced pressure to remove the excess amine to obtain the adduct; add the adduct to In the dispersing cylinder, after passing circulating water at 80°C, add 200g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com