Compound desulfurizer suitable for high oil content oil well and preparation method thereof

A technology of oil content and desulfurization agent, which is applied in the field of compound desulfurization agent and its preparation, can solve the problems of poor miscibility between desulfurization agent and crude oil, difficult handling of reaction products, and low antifreeze performance, so as to facilitate subsequent processing and prevent sulfide High effect of iron deposition and antifreeze performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the desulfurizer: adjust the pH to 7 with ethanolamine, place it at 0°C for 12 hours, put it into a three-necked flask, place it in an ice-water bath, add formaldehyde at 0°C for 12 hours, stir and adjust the pH to 8, and add a surfactant Stir for 10 minutes, store at 0°C for 2 hours, add small molecule alcohols, stir for 10 minutes, add water, continue stirring for 10 minutes, and blow liquid nitrogen for 10 minutes to obtain the product.

[0026] Among them, formaldehyde was added at a rate of 1.5 mL / min. After the formaldehyde was added, the stirring gradient was adjusted, and the pH was adjusted to 8 after rapid stirring for 1 hour and slow stirring for 0.5 hour.

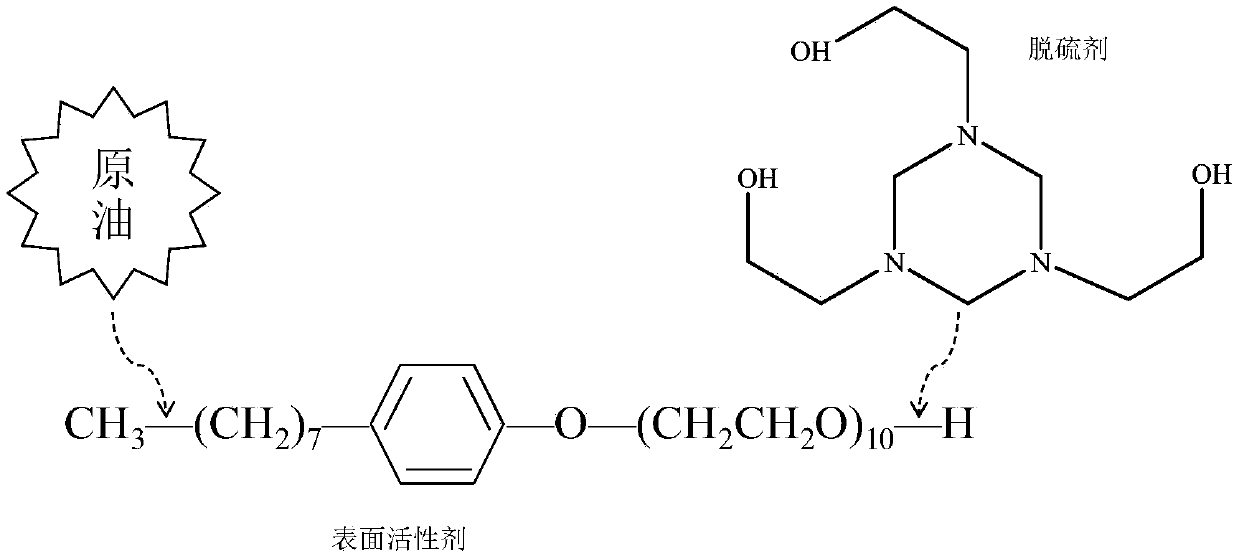

[0027] Principle of the present invention is:

[0028] The core component of the desulfurizer is the reaction product of aldehydes and alcohol amine compounds. It is easy to undergo a nucleophilic substitution reaction with hydrogen sulfide, and the nitrogen atom on the ring is e...

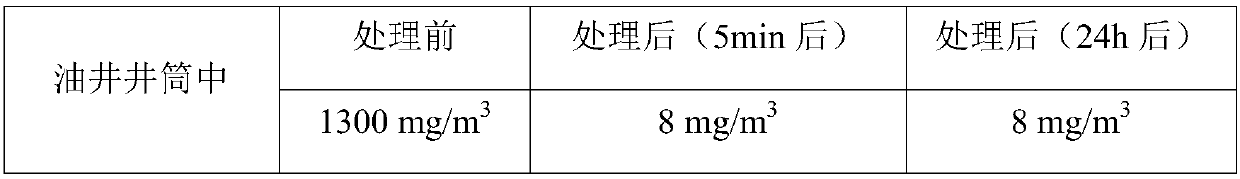

Embodiment 1

[0031] Adjust the pH to 7 with 42g of ethanolamine, place it at 0°C for 12h, put it into a 500mL three-necked flask, put it in an ice-water bath, add 42g of formaldehyde at a rate of 1.5mL / min, put it at 0°C for 12h, and adjust the stirring gradient, quickly Stir for 1 h, then slowly stir for 0.5 h, adjust the pH to 8, add 4 g of nonylphenol ethoxylate-10, stir rapidly for 10 min, and store at 0°C for 2 h. Add 2 g of ethanol, stir rapidly for 10 minutes, add water, continue stirring rapidly for 10 minutes, and then blow liquid nitrogen for 10 minutes to store.

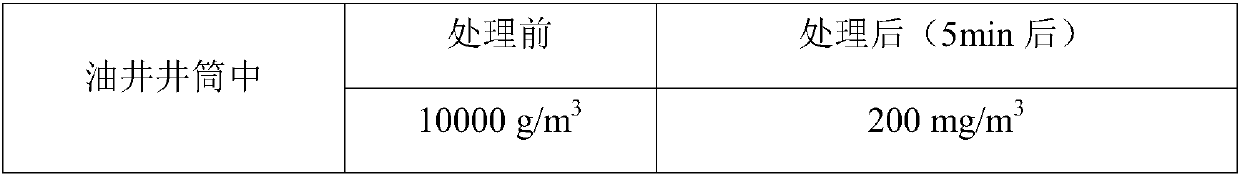

Embodiment 2

[0033] Operation method is the same as embodiment 1. The masses of the substances taken were: 42g ethanolamine, 46g formaldehyde, 11g alkylphenol polyoxyethylene ether-10, 5g methanol, and 96g water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com