Polycarboxylic acid polymer emulsifier and preparation method thereof

A polymer emulsifier, polycarboxylic acid technology, applied in the direction of botany equipment and methods, biocides, biocides, etc., can solve the problem of less application of small molecule emulsifiers, polymer emulsifiers, etc., to achieve excellent performance, good The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

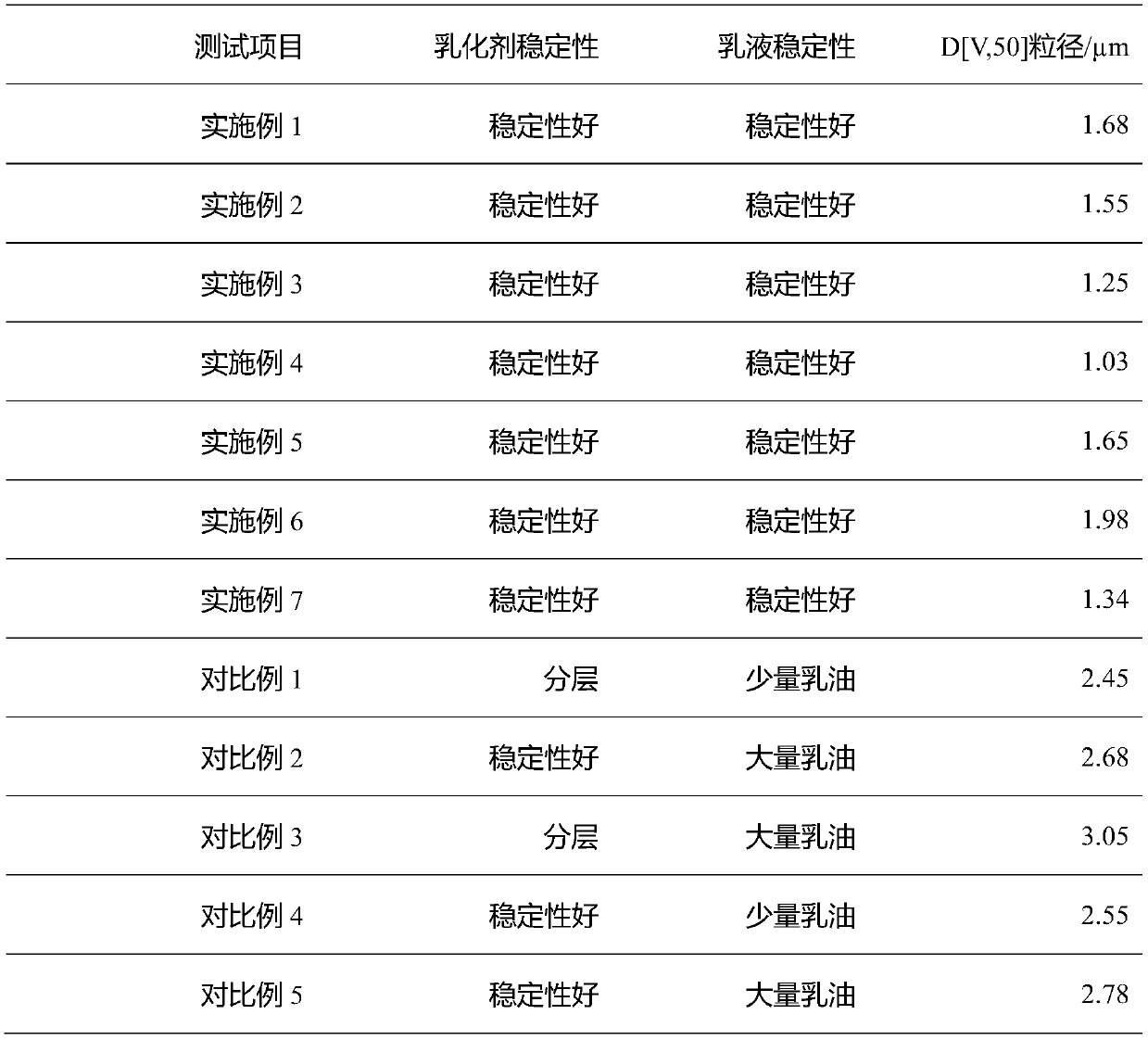

Embodiment 1

[0030] Polycarboxylic acid polymer emulsifier and its preparation method: add 100 parts of water and 50 parts of isopropanol into the reactor, and heat while stirring; when the temperature of the solution in the reactor rises to 70°C, drop 10 Parts of acrylic acid, 15 parts of isooctyl acrylate and 30 parts of initiator ammonium persulfate solution were added dropwise within 1 hour, and then incubated for 2 hours; after the insulation reaction was completed, the temperature was cooled to room temperature while stirring, and the pH was adjusted with sodium hydroxide solution to 7.2, that is, the polymer emulsifier is prepared.

[0031] The weight-average relative molecular weight of the polymer emulsifier detected by GPC is 38800.

Embodiment 2

[0033] Polycarboxylate polymer emulsifier and its preparation method: Add 100 parts of water and 50 parts of isopropanol into the reactor, and heat while stirring; when the temperature of the solution in the reactor rises to 80°C, drop 15 Parts of acrylic acid, 20 parts of isooctyl acrylate and 30 parts of initiator ammonium persulfate solution were added dropwise within 1 hour, and then incubated for 2 hours; after the insulation reaction was completed, the temperature was cooled to room temperature while stirring, and the pH was adjusted with sodium hydroxide solution to 7.2, that is, the polymer emulsifier is prepared.

[0034] The weight-average relative molecular weight of the polymer emulsifier detected by GPC is 40600.

Embodiment 3

[0036] Polycarboxylate polymer emulsifier and its preparation method: add 100 parts of water and 50 parts of isopropanol into the reactor, heat while stirring; when the temperature of the solution in the reactor rises to 85°C, add 15 parts dropwise Parts of acrylic acid, 20 parts of isooctyl acrylate and 30 parts of initiator ammonium persulfate solution were added dropwise within 1.5 hours, and then incubated for 2 hours; after the insulation reaction was completed, the temperature was cooled to room temperature while stirring, and the pH was adjusted with sodium hydroxide solution to 7.2, that is, the polymer emulsifier is prepared.

[0037] The weight-average relative molecular weight of the polymer emulsifier detected by GPC is 41500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com