Low temperature cured solvent-free epoxy anticorrosion paint and its preparation method

An epoxy anti-corrosion coating, solvent-free technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of limited low-temperature workability, large temperature dependence, slow, stop below 5 ℃, etc. Excellent physical and mechanical properties, energy saving, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

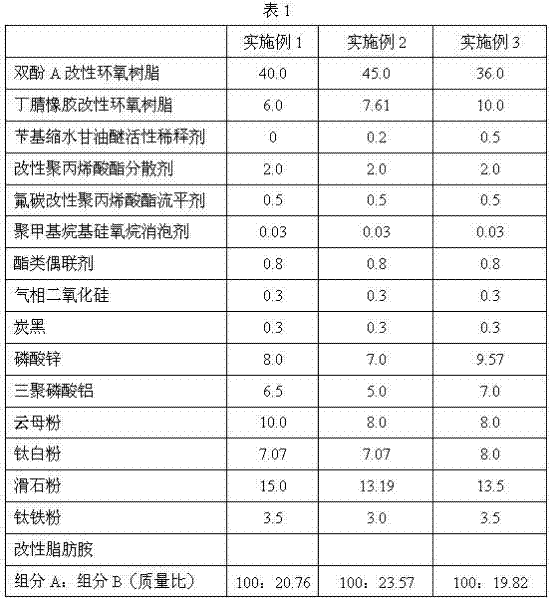

[0029] The raw material ratio (percentage by weight) of Examples 1 to 3 is shown in Table 1 below:

[0030]

[0031] According to the ratio of Example 1 in the above table 1, add nitrile rubber modified epoxy resin to bisphenol A modified epoxy resin, then stir until uniform, and then add various additives and inorganic pigments and fillers in sequence according to the proportion , Stir at room temperature and grind to ≤60μm, filter after passing. When in use, mix according to the mass ratio of component A: component B = 100: 20.76, the measured adhesion (cross-cut method) is grade 1, the flexibility is 1mm, and the impact strength is 50kg·cm.

Embodiment 2

[0033] According to the proportion of Example 2 in the above table 1, add nitrile rubber modified epoxy resin and benzyl glycidyl ether to bisphenol A modified epoxy resin, then stir until uniform, and then add various Additives and inorganic pigments and fillers, after stirring at room temperature, grind to ≤60μm, and filter after passing the test. When in use, mix according to the mass ratio of component A: component B = 100: 23.57, the measured adhesion (cross-cut method) is grade 1, the flexibility is 1mm, and the impact strength is 50kg·cm.

Embodiment 3

[0035] According to the proportion of Example 3 in the above table 1, add nitrile rubber modified epoxy resin and benzyl glycidyl ether to bisphenol A modified epoxy resin, then stir until uniform, and then add various Additives and inorganic pigments and fillers, after stirring at room temperature, grind to ≤60μm, and filter after passing the test. When in use, mix according to the mass ratio of component A:component B=100:19.82, the measured adhesion (cross-cut method) is grade 1, the flexibility is 1mm, and the impact strength is 50kg·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com