Method for making metalized half hole

A technology of metallized half-holes and manufacturing methods, applied in the direction of electrical connection formation of printed components, etc., can solve problems such as the adverse effects of solder mask and surface treatment, damage to the lead-tin corrosion layer, and increased drilling costs, so as to improve production Efficiency and quality, avoiding copper exposure, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

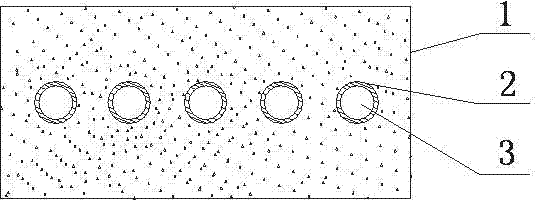

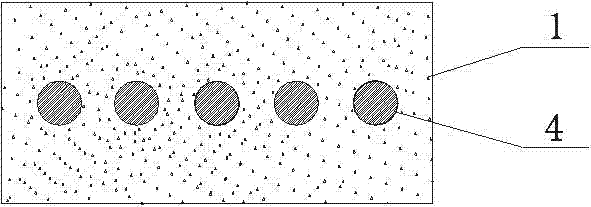

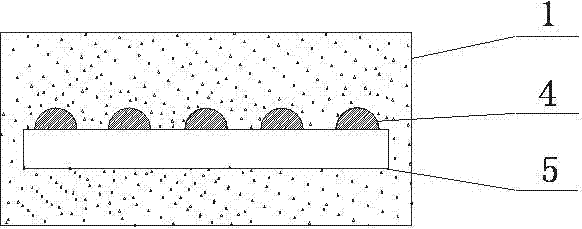

[0023] As shown in the accompanying drawings, a manufacturing method of a metallized half-hole of the present invention of this patent includes, in the production process of the printed board, after the photosensitive solder resist process is completed, the metallized half-hole to be processed on the printed board is processed. Fill the holes with tin, then mill out half of the holes according to the design requirements, and then carry out hot air leveling; the specific process is:

[0024] Step 1: Firstly, blanking, drilling, copper sinking, pattern transfer, pattern electroplating, stripping, etching, and photosensitive solder resist are sequentially performed on the double-sided copper clad board to obtain a semi-finished product with metallized half-holes 3 to be processed Printed board; the metallized semi-hole 3 to be processed here is a circular hole obtained through a drilling process on the printed board.

[0025] Step 2, tin filling treatment: immerse the metalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com