Covering yarn production device and method

The technology of a production device and production method, which is applied in the field of textile manufacturing and processing, can solve the problems affecting the quality of the core-spun yarn and unfavorable filament coating, etc., and achieve the effects of good evenness, high strength and improved yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

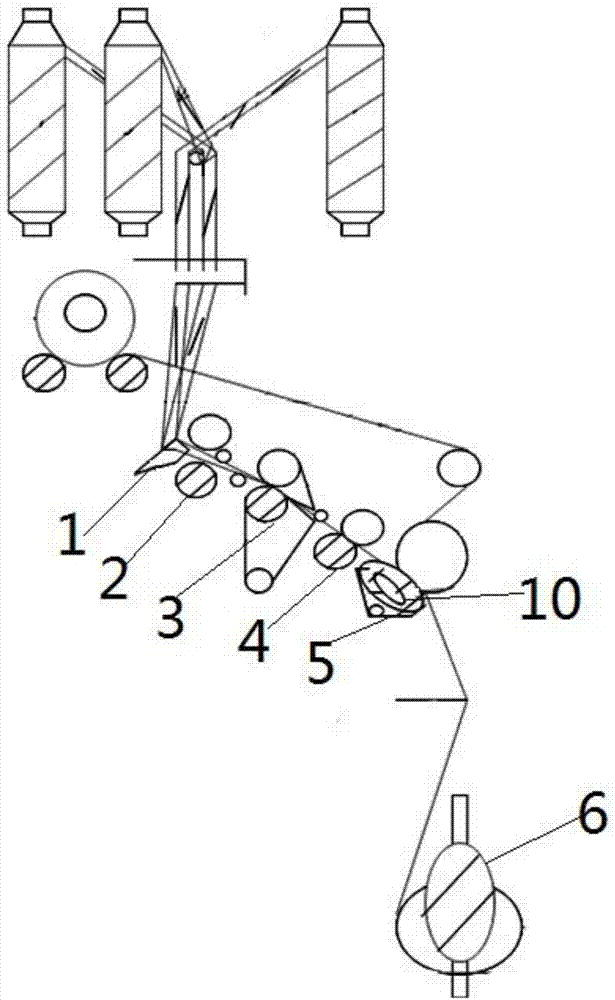

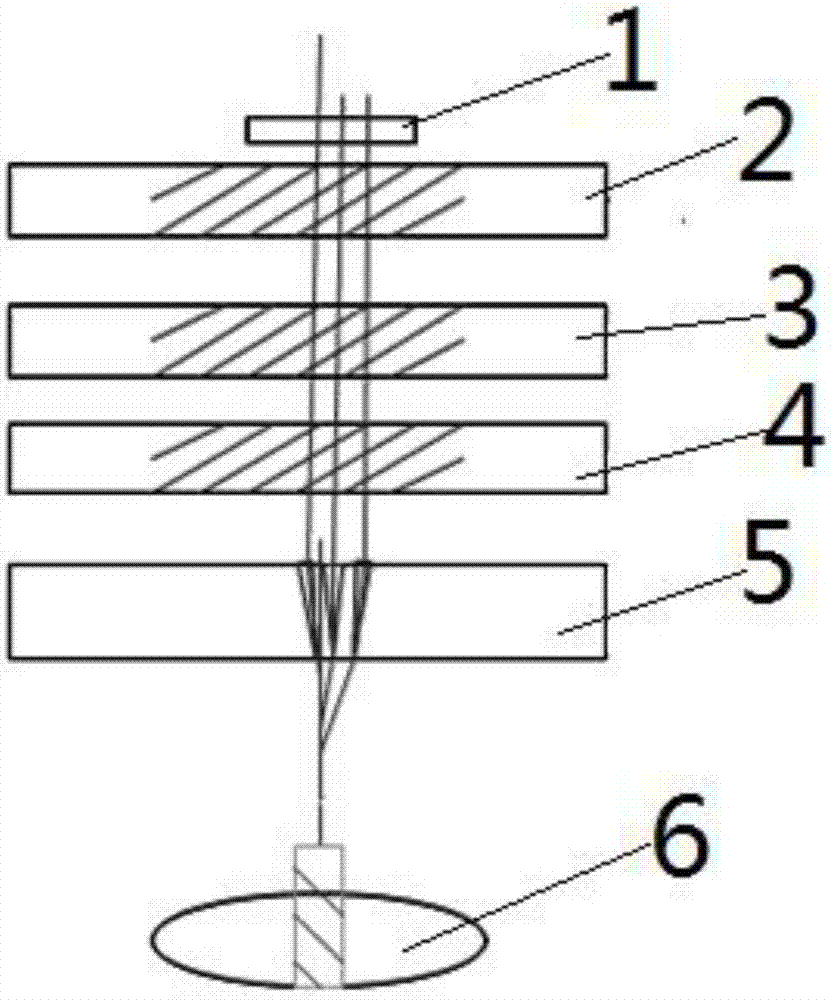

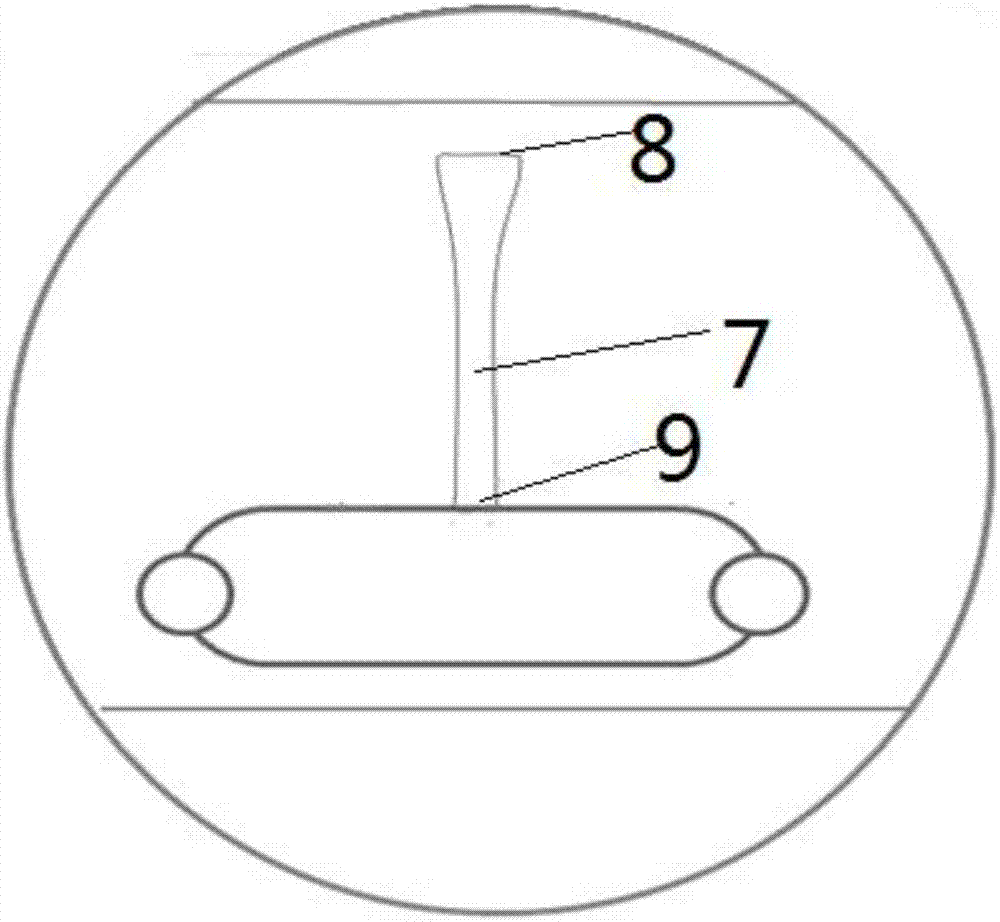

[0037] see Figure 1~4 , a core-spun yarn production device provided in an embodiment of the present invention, which sequentially includes a bell mouth 1, a first roller 2, a second roller 3, a third roller 4, a negative pressure tube 5 and a steel ring 6 from top to bottom, It is characterized in that a groove 7 is provided on the negative pressure tube 5, the groove 7 includes a first port 8 and a second port 9, the first port 8 is arranged above the second port 9, the The width of the first port 8 is greater than the width of the second port 9 .

[0038] The specific working process of this application: lead out the strands from the roving processed by the pre-spinning processes, feed the strands into the bell mouth 1 after passing through the yarn guide rod, and enter the drafting system after passing through the bell mouth 1, the first The top roller after the first roller 2 rotates to hold the strands and feeds them into the gripping area formed by the second roller 3 ...

Embodiment 2

[0040] see Figure 1~4 , a core-spun yarn production device provided in an embodiment of the present invention, which sequentially includes a bell mouth 1, a first roller 2, a second roller 3, a third roller 4, a negative pressure tube 5 and a steel ring 6 from top to bottom, It is characterized in that a groove 7 is provided on the negative pressure tube 5, the groove 7 includes a first port 8 and a second port 9, the first port 8 is arranged above the second port 9, the The width of the first port 8 is greater than the width of the second port 9 .

[0041] Optionally, the groove 7 includes a wedge-shaped groove, and the wedge-shaped groove is perpendicular to the negative pressure tube 5 .

[0042] Optionally, the groove 7 is in a "Y" shape, the first port 8 is 4.5 mm wide, and the second port 9 is 2.7 mm wide.

[0043] Optionally, a grid ring 10 is arranged on the groove 7 .

[0044]The specific working process of this application: lead out the strands from the roving pr...

Embodiment 3

[0047] see Figure 1~4 , a core-spun yarn production device provided in an embodiment of the present invention, which sequentially includes a bell mouth 1, a first roller 2, a second roller 3, a third roller 4, a negative pressure tube 5 and a steel ring 6 from top to bottom, It is characterized in that a groove 7 is provided on the negative pressure tube 5, the groove 7 includes a first port 8 and a second port 9, the first port 8 is arranged above the second port 9, the The width of the first port 8 is greater than the width of the second port 9 .

[0048] Optionally, the groove 7 is radial, and the groove 7 includes several first ports 8 .

[0049] Optionally, the groove 7 includes three first ports 8, and the width of the first ports 8 is 1mm.

[0050] Optionally, a grid ring 10 is arranged on the groove 7 .

[0051] The specific working process of this application: lead out the strands from the roving processed by the pre-spinning processes, feed the strands into the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com