Silicon-carbon composite negative electrode material for lithium-ion battery and preparation method thereof

A lithium-ion battery, silicon-carbon composite technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem of incomplete liquid phase coating, poor silicon dispersion, poor cycle performance, etc. problems, to avoid direct contact, prevent agglomeration, and evenly disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of silicon-carbon composite negative electrode material for lithium ion battery of the present invention comprises the following steps:

[0033] (1) Dispersing the micron silicon in an organic solvent and grinding it to form a nano-silicon slurry;

[0034] (2) adding the carbon matrix, binder, and conductive agent into the organic solvent and mixing uniformly to obtain slurry 1; adding the nano-silicon slurry in (1) to slurry 1, and mixing uniformly to obtain slurry 2;

[0035] (3) drying the slurry 2 to obtain a precursor material 1; merging the precursor material 1 and the coating agent to obtain a precursor material 2; placing the precursor material 2 in a protective atmosphere for heat treatment to obtain a precursor material 3;

[0036] (4) crushing and grading the precursor material 3, then mixing with the coating agent, and coating at high temperature to obtain the precursor material 4;

[0037] (5) Precursor material 4 is placed in a prot...

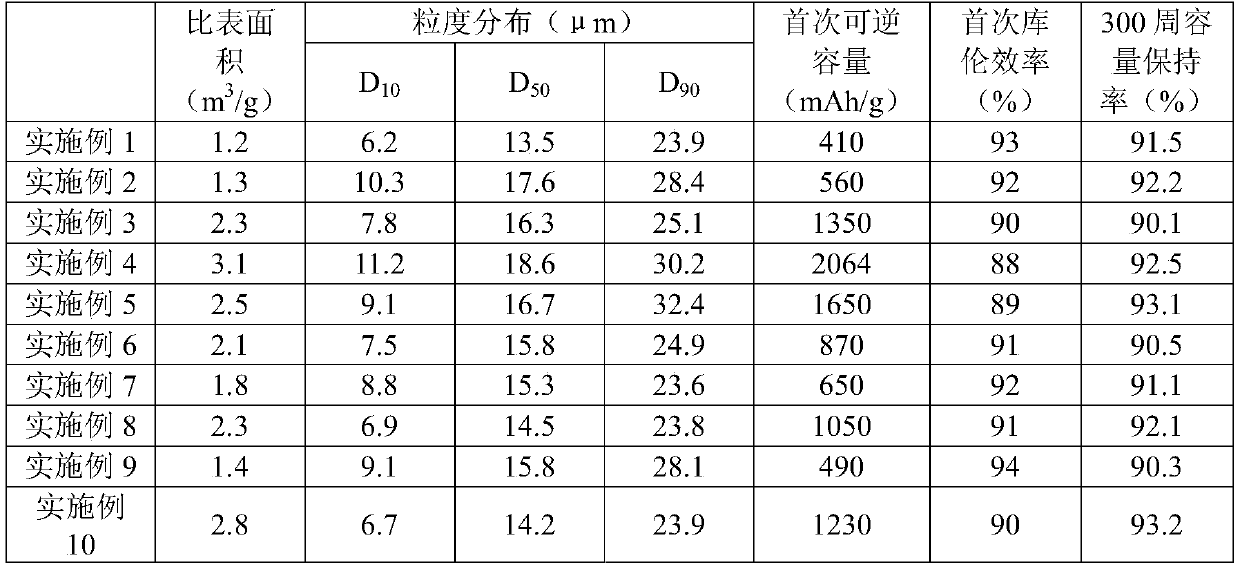

Embodiment 1

[0048] Disperse 100g of silicon powder with a median particle size of 5 μm into 1000 g of ethanol solvent, add to a ball mill and ball mill to obtain a nano-silicon slurry with a median particle size of 150 nm; 1570 g of spherical natural graphite with a median particle size of 12 to 14 μm, Add polyvinylpyrrolidone, 15g conductive carbon black and 5680g ethanol solvent to stir and mix to obtain slurry 1; add the above nano-silicon slurry to slurry 1, stir and mix to obtain slurry 2; spray dry slurry 2 to obtain precursor material 1. The inlet temperature of spray drying is 150°C, the outlet temperature is 80°C, and the rotation speed of the atomizer is 20000rpm / min; the precursor material 1 and 252g of coal tar pitch are mixed, added to the fusion machine for fusion coating, and the precursor material 2 is obtained, and the distance between the knives of the fusion machine 0.1mm, rotation speed 5000rpm / min, fusion time 5min; put the precursor material 2 in a box furnace, in a n...

Embodiment 2

[0050] Disperse 200g of silicon powder with a median particle size of 1μm into 1500g of ethylene glycol solvent, add to a ball mill and ball mill to obtain a nano-silicon slurry with a median particle size of 100nm; 1450g of artificial graphite with a median particle size of 15-17μm, 20g polyvinyl butyral, 15g graphene are added 5180g ethylene glycol solvent and stir and mix, obtain slurry 1; Add above-mentioned nano-silicon slurry to slurry 1, stir and mix to obtain slurry 2; Slurry 2 is spray-dried , the precursor material 1 was obtained, the inlet temperature of spray drying was 180°C, the outlet temperature was 90°C, and the rotation speed of the atomizer was 10,000rpm / min; the precursor material 1 was mixed with 315g of coal tar pitch, and added to the fusion machine for fusion coating, and the precursor material 2 was obtained , fusion machine knife spacing 0.5mm, rotation speed 3500rpm / min, fusion time 30min; put the precursor material 2 in a roller kiln, in an argon atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com