Double-layer knitted fabric and weaving method thereof

A technology for knitted fabrics and fabrics, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of large differences in dye uptake, damage to the microcapsule structure, and differences in hand feel and style, so as to improve moisture conductivity, Improved comfort and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A two-ply knitted fabric with a connection point density of 12.5% is produced.

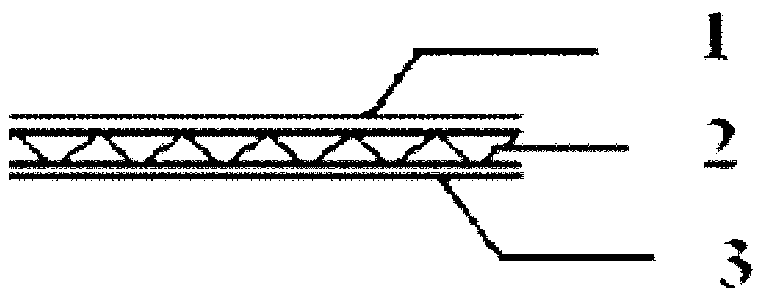

[0038] This example (see figure 2) The double-layer knitted fabric includes surface fabric 1 or outer fabric 1, inner fabric 3 and middle connecting yarn 2, the surface fabric 1 is woven from the surface yarn, and the inner fabric 2 is made of the inner yarn The outer and inner layers of fabric are connected by connecting yarn 2 to form a whole double-layer knitted fabric. The surface layer yarn is spun from cashmere fiber, and the inner layer yarn is regulated by heat storage. The warm fiber and the cashmere fiber are blended at a mass ratio of 40:60, and the connecting yarn 2 is purely spun from the heat storage and temperature regulating fiber. The specifications of the heat storage and temperature regulating fibers are: length 40mm, fineness 2.0dtex; the specifications of cashmere fibers are: length 40mm, fineness 15um.

[0039] The fabric is woven on a computerized flat knitting m...

Embodiment 2

[0042] A two-ply knitted fabric with a connection point density of 25% is produced.

[0043] The yarn configuration of this embodiment is: the mass mixing ratio is 30:70, and the connecting yarn is spun from heat-storing and temperature-regulating fibers; the specifications of the heat-storing and temperature-regulating fibers are: length 42mm, fineness 2.2mm dtex; cashmere fiber specifications: length 44mm, fineness 16um.

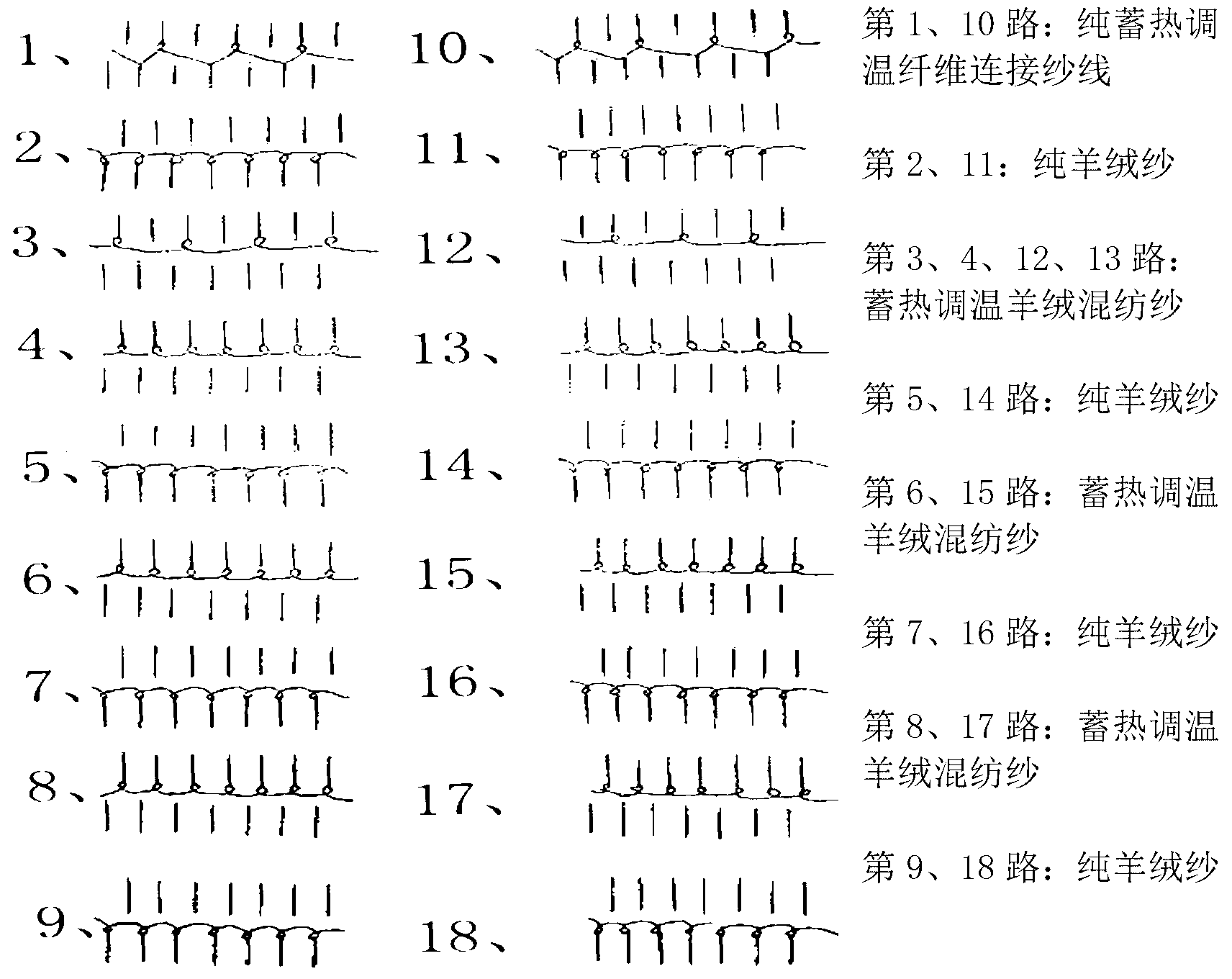

[0044] Its braiding method is basically the same as in embodiment 1. Please refer to the specific weaving structure diagram image 3 . image 3 The knitting diagram of knitting double-layer knitted fabrics for 10 knitting systems, in which the surface yarns are respectively formed into full loops on the lower needles of 2, 5, 7 and 10 knitting systems, and the inner yarns are respectively 3, 4 and 8 , 9. Knitting is formed on the upper needle of the knitting system, and the connecting yarns are respectively knitted on the upper needles of the 1 and 6 kn...

Embodiment 3

[0046] A two-ply knitted fabric with a connection point density of 50% is produced.

[0047] The yarn configuration of this embodiment is: the mass mixing ratio is 70:30. The connecting yarn 2 is spun from heat-storing and temperature-regulating fibers; the specifications of the heat-storing and temperature-regulating fibers are: length 38mm, fineness 1.7dtex; specifications of cashmere fibers are: length 36mm, fineness 14um.

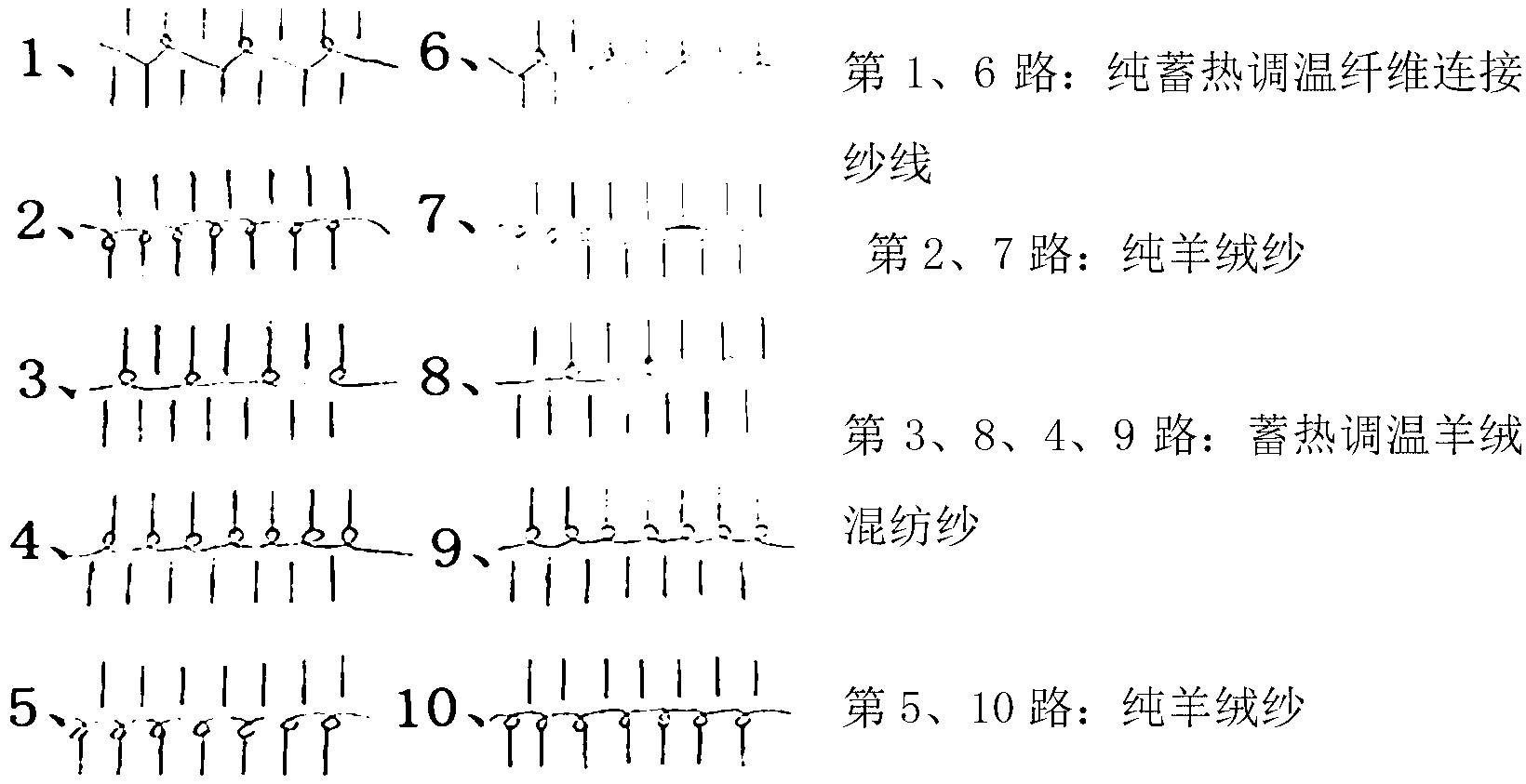

[0048] Its braiding method is basically the same as in embodiment 1. Refer to the specific weaving structure diagram Figure 4 . Figure 4 The knitting diagram of knitting double-layer knitted fabrics for 6 knitting systems, in which the surface yarns are respectively on the lower needles of 2 and 5 knitting systems to form full loops, and the inner yarns are respectively on the upper needles of 3 and 6 knitting systems The upper loop is formed, and the connecting yarn 2 is looped on the upper needle in the 1 and 4 loop forming systems respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com