A kind of preparation method of multifunctional microfiber synthetic leather

A technology of superfine fiber and synthetic leather, which is applied in the direction of plant fiber, fiber treatment, fiber type, etc., and can solve the problems of high product price and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

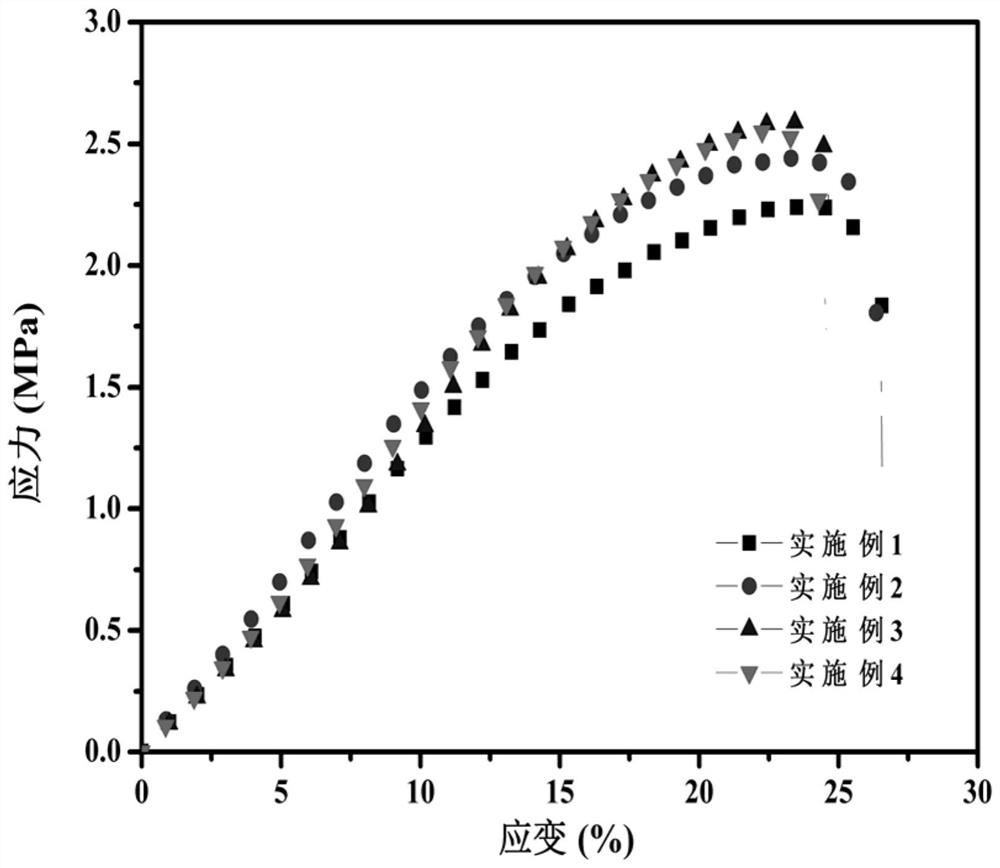

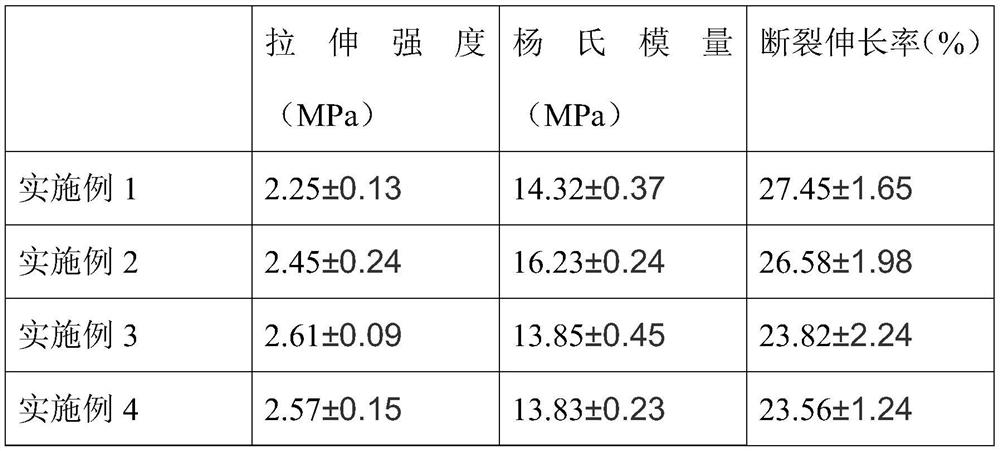

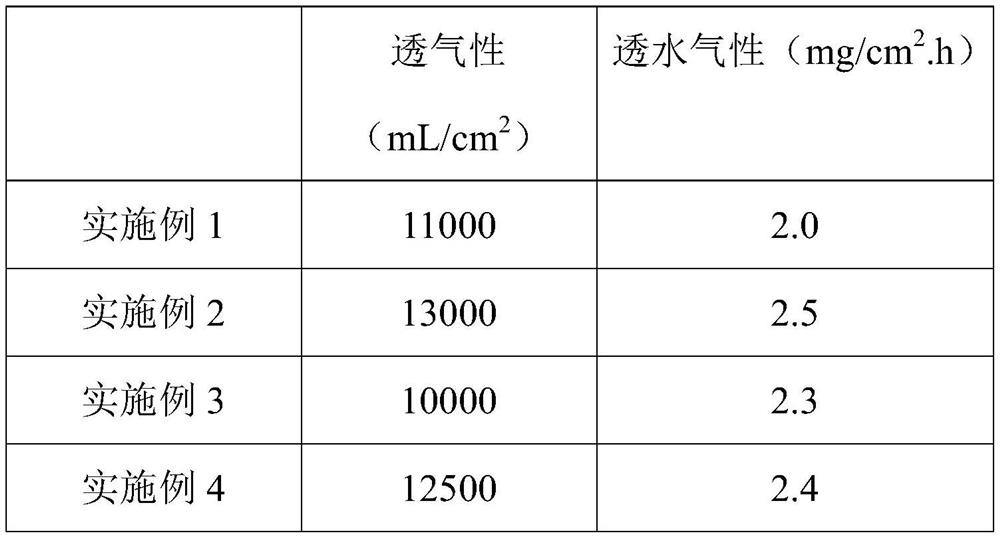

Examples

Embodiment 1

[0029] 1. Preparation of superfine fiber / nanocellulose base cloth:

[0030] Take 10g of PA6 / EHDPET sea-island fibers and immerse them in 200mL of deionized water, heat at 80°C for 4h, then take out the PA6 / EHDPET sea-island fibers to obtain PA6 microfibers with the "sea" phase removed;

[0031] Add 10g of PA6 microfibers with a mass fraction of 1wt% to 100g of nanocellulose aqueous solution, wherein the mass fraction of cellulose in the nanocellulose solution is 1wt%, and at the same time add KH550 with a mass fraction of 2wt%, and stir for 2 hours at room temperature , the superfine fiber / nanocellulose mixed solution was frozen at -80°C for 1 hour and then transferred to a freeze dryer. fabric;

[0032] Take 10g of the prepared microfiber / nanocellulose base cloth, immerse it in 100g of DMF solution with 5% mass fraction PEG1000, then add 5g of 1-octyl isocyanate, stir for 4h and mix the microfiber / nanocellulose base cloth The cloth was vacuum dried for 8 hours, and finally ...

Embodiment 2

[0038] 1. Preparation of superfine fiber / nanocellulose base cloth:

[0039] Take 10g of PET / EHDPET sea-island fibers and immerse them in 200mL of deionized water, heat at 80°C for 6 hours, then take out the PET / EHDPET sea-island fibers to obtain PET microfibers with the "sea" phase removed;

[0040] Add 10g of 2wt% PET ultrafine fibers to 100g of nanocellulose aqueous solution, wherein the nanocellulose in the nanocellulose solution is 2wt%, and at the same time add KH560 with a mass fraction of 4wt%, and stir for 2 hours at room temperature Finally, the superfine fiber / nanocellulose mixed solution was frozen at -90°C for 1 hour and then transferred to a freeze dryer. plain cloth;

[0041] Take 10g of the prepared microfiber / nanocellulose base cloth, immerse in 100g of DMF solution with 5% mass fraction PEG2000, add 5g of hexyl isocyanate, stir for 4h and put the ultrafine fiber / nanocellulose base cloth After vacuum drying for 8 hours, the superfine fiber / nanocellulose base ...

Embodiment 3

[0047] 1. Preparation of superfine fiber / nanocellulose base cloth:

[0048] Take 10g of PA6 / EHDPET sea-island fibers and immerse them in 200mL of deionized water, heat at 80°C for 5h, then take out the PA6 / EHDPET sea-island fibers to obtain PA6 microfibers with the "sea" phase removed;

[0049] Add 10g of 1.5wt% PET microfibers into 100g of nanocellulose aqueous solution, wherein the nanocellulose in the nanocellulose solution is 1.5wt%, while adding 1.5wt% of A-151 , after stirring at room temperature for 2 hours, the superfine fiber / nanocellulose mixed solution was frozen at -80°C for 1 hour and then transferred to a freeze dryer. The freeze-drying temperature was -40°C and the freeze-drying time was 55 hours. Fine fiber / nanocellulose base cloth;

[0050] Take 10g of the prepared microfiber / nanocellulose base cloth, immerse it in 100g of DMF solution with 5% mass fraction PEG4000, then add 5g of isopropyl isocyanate, stir for 4h, and mix the microfiber / nanocellulose base cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com