Micro evaporator, oscillator-integrated micro evaporator structure and frequency correction method thereof

An evaporator and oscillator technology, applied in the sensing field, can solve the problems of inability to achieve oscillator frequency calibration and high oscillator frequency dispersion, and achieve the effects of small heat capacity, improved accuracy, and less heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

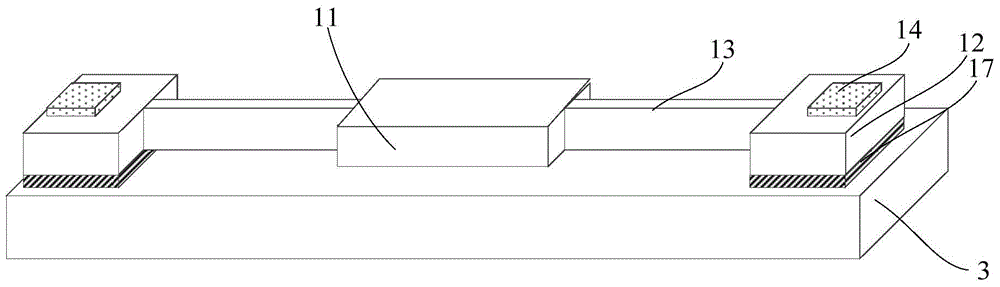

[0089] see figure 1 , the present invention provides a kind of micro-evaporator, described micro-evaporator comprises: micro-evaporation table 11, anchor point, support beam and metal electrode; and the metal electrodes are respectively defined as the first anchor point 12, the first support beam 13 and the first metal electrode 14;

[0090] One side of the micro-evaporation table 11 is an evaporation surface; the first anchor point 12 is located on both sides of the micro-evaporation table 11, and is separated from the micro-evaporation table 11 by a certain distance; the first support beam 13 Located between the micro-evaporation table 11 and the first anchor point 12, one end is connected to the micro-evaporation table 11, and the other end is connected to the first anchor point 12; the first support beam 13 Dimensions (ie length, width, height) satisfy the following relationship: Wherein, b, h, L are respectively the width, thickness and length of the support beam, T is...

Embodiment 2

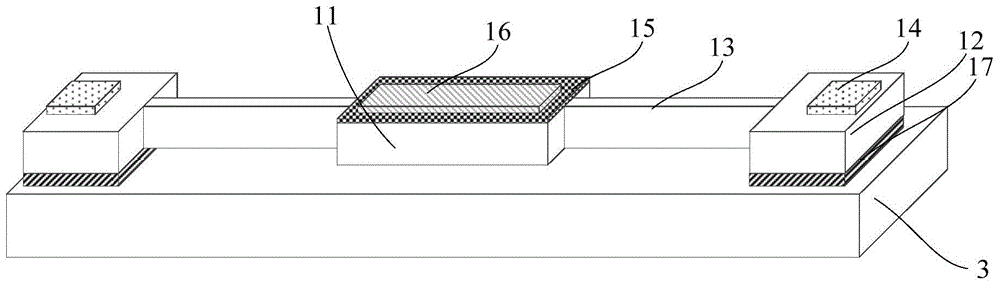

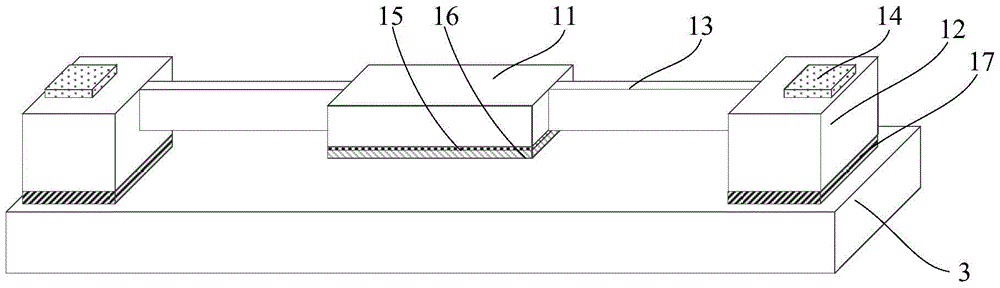

[0098] see Figure 2 to Figure 3 , the present invention also provides a micro-evaporator, the structure of the micro-evaporator is roughly the same as that of the micro-evaporator described in the first embodiment, and the micro-evaporator in the present embodiment is compared with the The difference between the micro-evaporators described in:

[0099] The micro-evaporator also includes an evaporation material 16 , and the evaporation material 16 is located on the evaporation surface of the micro-evaporation table 11 .

[0100] As an example, when the saturated vapor pressure of the evaporating material 16 is greater than 10 -6 The temperature of Torr is lower than the melting point of the micro-evaporation platform 11, and the evaporation material 16 can be selected from metal, semiconductor or insulating materials, such as aluminum, germanium, gold or semiconductor materials such as silicon and germanium. When the micro-evaporator is integrated with the oscillator to revi...

Embodiment 3

[0106] see Figure 4 , the present invention provides an oscillator-integrated micro-evaporator structure, the oscillator-integrated micro-evaporator structure includes the micro-evaporator and the oscillator as described in Embodiment 1;

[0107] The micro-evaporator and the oscillator are jointly sealed in the same vacuum chamber, the micro-evaporator and the oscillator are arranged correspondingly up and down, and the evaporation surface of the micro-evaporation platform 11 in the micro-evaporator faces the oscillator device.

[0108] As an example, the oscillator can be a quartz oscillator, a silicon-based MEMS oscillator, or other oscillators, and there is no limitation on the type and structure of the oscillator, that is, the oscillator Any existing oscillator can be used.

[0109] In this embodiment, taking a bending mode oscillator as an example, the oscillator includes a resonant unit 21, a second support beam 22, a second anchor point 23, and a second metal electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com