Composite board for high temperature mixture product mold and production process

A composite plate, high-temperature mixing technology, applied in the direction of synthetic resin layered products, layered products, natural mineral layered products, etc., can solve the problems of high-temperature mixture and mold temperature difference, poor thermal conductivity, etc., to ensure smooth surface High temperature, high temperature stability, saving material and time cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

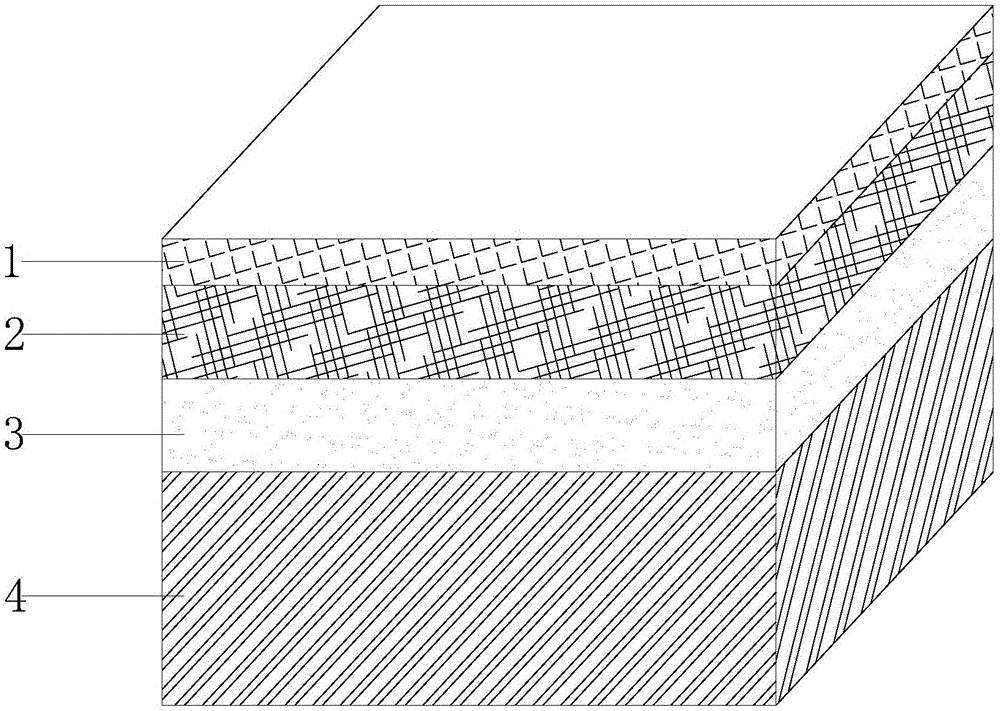

[0022] The composite sheet for the part mold includes ordinary sheet, pyrophyllite powder, high-temperature glue, mica sheet 2 and flame-retardant polycarbonate film 1; The inner wall structure layer is composed of ordinary board 4, pyrophyllite powder and high-temperature glue mixture 3, mica board 2, and flame-retardant polycarbonate film 1.

[0023] in:

[0024] a. Pyrophyllite powder: particle size ≥ 400 mesh, refractoriness > 1500°C, baked at 200°C for 24 hours, moisture < 0.5%;

[0025] b. High-temperature glue: high-temperature glue above 400°C is used, and the long-term temperature resistance is >350°C;

[0026] c. Mica board: temperature resistance grade: 500°C for continuous use, 850°C for intermittent use; flexural strength > 200MPa, water absorption < 1%, thickness 0.2-10mm;

[0027] d. Flame-retardant polycarbonate film: thickness 0.03-3.0mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com