Heat-insulating and drop-resistant ceramic cup and manufacturing method thereof

A production method and technology for ceramic cups, applied in the field of ceramic cups, can solve the problems of poor thermal insulation performance, easy breaking of the ceramic cup body, etc., and achieve the effects of good thermal insulation, avoiding scalding and improving thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

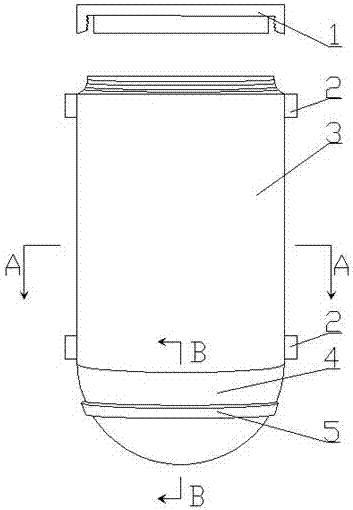

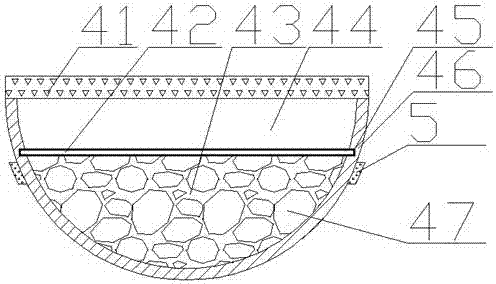

[0047] refer to Figure 1~4 , a heat-insulating and drop-proof ceramic cup of this embodiment, comprising a cup body 3, a honeycomb paperboard 32, a tumbler-shaped base and a cup cover 1, and the cup body 3 is composed of an integrally formed inner cup body 31 and an outer cup body 33 , Between the inner cup body 31 and the outer cup body 33, there is a cavity 34 for honeycomb cardboard 32, the bottom of which is fixed on the tumbler base 4, and the cup cover 1 is screwed to the cup body 3.

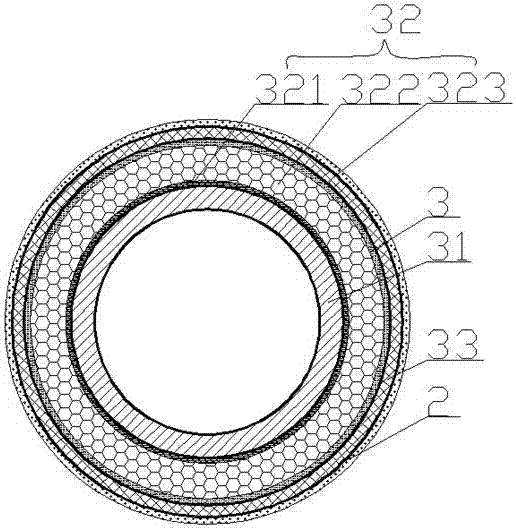

[0048] refer to figure 2 and 4, the honeycomb paperboard 32 includes a honeycomb paper core 322 composed of several honeycomb cells, an aluminum foil board 321 and an airgel felt board 323 respectively connected to both sides of the honeycomb paper core 322, and the aluminum foil board 321 of the honeycomb paper board 32 is close to The side of the inner cup body 31 and the side of the airgel felt board 323 close to the outer cup body 33 are placed in the placement cavity 34 .

[0049...

Embodiment 2

[0056] refer to Figure 5~7 , a heat-insulating and drop-proof ceramic cup of this embodiment, comprising a cup body 3, a honeycomb paperboard 32 and a tumbler-shaped base, the cup body 3 is composed of an integrally formed inner cup body 31 and an outer cup body 33, the inner cup body 31 and the outer cup body 33 are provided with a placement cavity 34 of honeycomb cardboard 32 , the bottom of which is fixed on the tumbler base 4 .

[0057] The honeycomb paperboard 32 includes a honeycomb paper core 322 composed of several honeycomb cells, an aluminum foil board 321 and an airgel felt board 323 respectively connected to both sides of the honeycomb paper core 322, and the aluminum foil board 321 of the honeycomb paper board 32 is close to the inner One side of the cup body 31 and the side of the airgel felt plate 323 close to the outer cup body 33 are placed in the placing cavity 34 .

[0058] The honeycomb cells are triangular in shape.

[0059] The thickness of the honeyco...

Embodiment 3

[0067] refer to Figure 8 , a heat-insulating anti-fall ceramic cup of this embodiment, compared with Embodiment 2, has the following differences:

[0068] The ceramic cup also includes a cup cover 1 , and the cup cover 1 is hingedly connected with the cup body 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com