Printed circuit board

A technology for printed circuit boards and plug-in holes, which is applied in the fields of printed circuit, printed circuit, and printed circuit manufacturing. It can solve the problems of poor soldering of plug-in components and large heat dissipation area, so as to reduce the area, slow down the heat dissipation speed, and avoid welding. bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

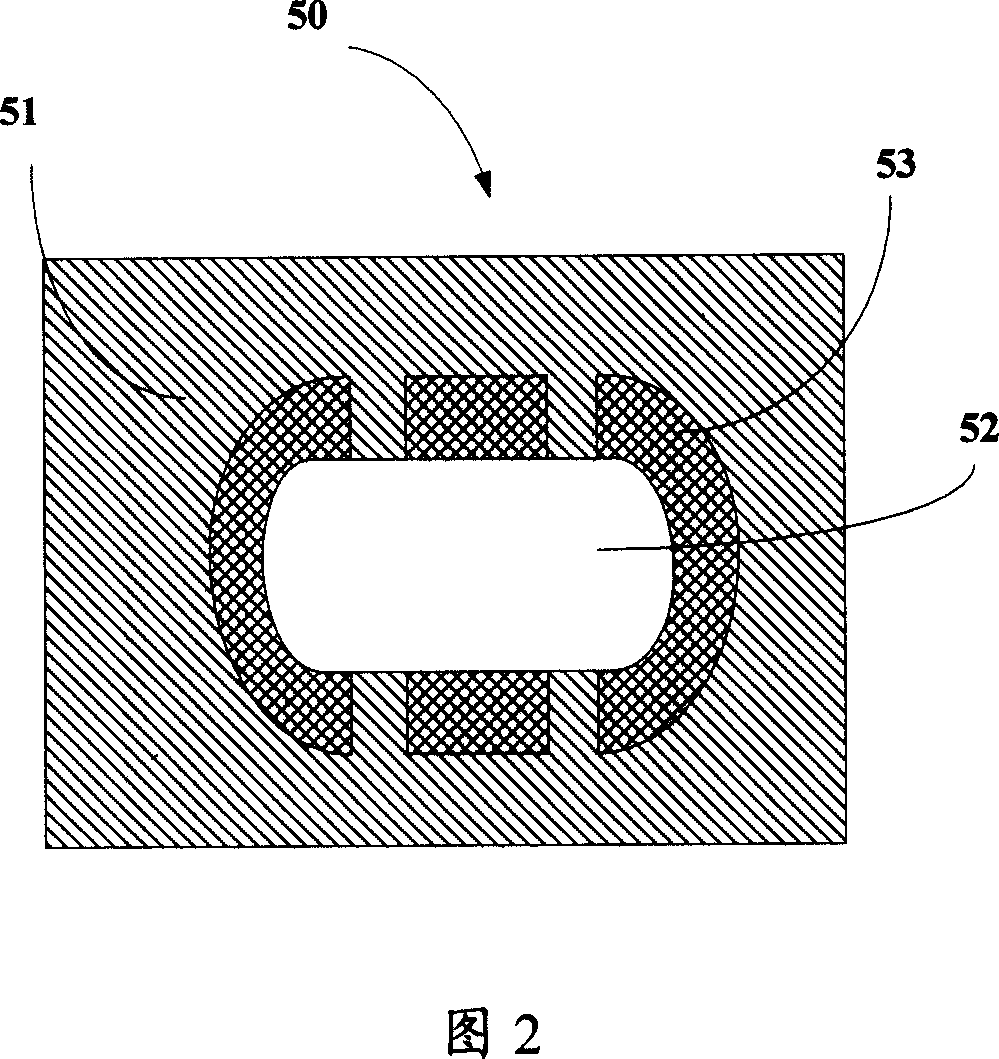

[0011] Please refer to FIG. 2 , which is a schematic plan view of the metal layer of a preferred embodiment of the printed circuit board of the present invention.

[0012] A printed circuit board 50 includes a metal layer 51 , an insertion hole 52 , and four insulating regions 53 , and the insulation regions 53 are spaced apart from each other and surround the insertion hole 52 . The metal layer 51 is a layer of copper foil, and the copper foil around the insertion hole 52 is separated by the insulating area 53 to form a strip, and the metal layer 51 is inserted into the insert through the strip. The plug-in assembly in hole 52 conducts. The width of the insulating region 53 is 14 mils. The strips were 15 mils wide.

[0013] Compared with the existing printed circuit board, the present invention reduces the heat dissipation area of the copper foil around the plug-in hole of the metal layer of the printed circuit board, slows down the heat dissipation speed of the printed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com