Inner pot used for cooking utensil, cooking utensil and method for manufacturing inner pot

A technology for cooking utensils and inner pots, which is applied to special materials for cooking utensils, kitchen utensils, cooking utensils, etc., which can solve the problems of respiratory diseases, dust inhalation into the lungs, and high cost of inner pots, and achieve the purpose of inhibiting bacterial growth, low cost, The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following discussion, details are given in order to provide a more thorough understanding of the invention. However, it will be apparent to those skilled in the art that the present invention may be practiced without one or more of these details. In certain examples, in order to avoid confusion with the present invention, some technical features known in the art are not described in detail. It should be noted that the terms "upper", "lower", "front", "rear", "left", "right" and similar expressions used herein are for the purpose of illustration only, not limitation.

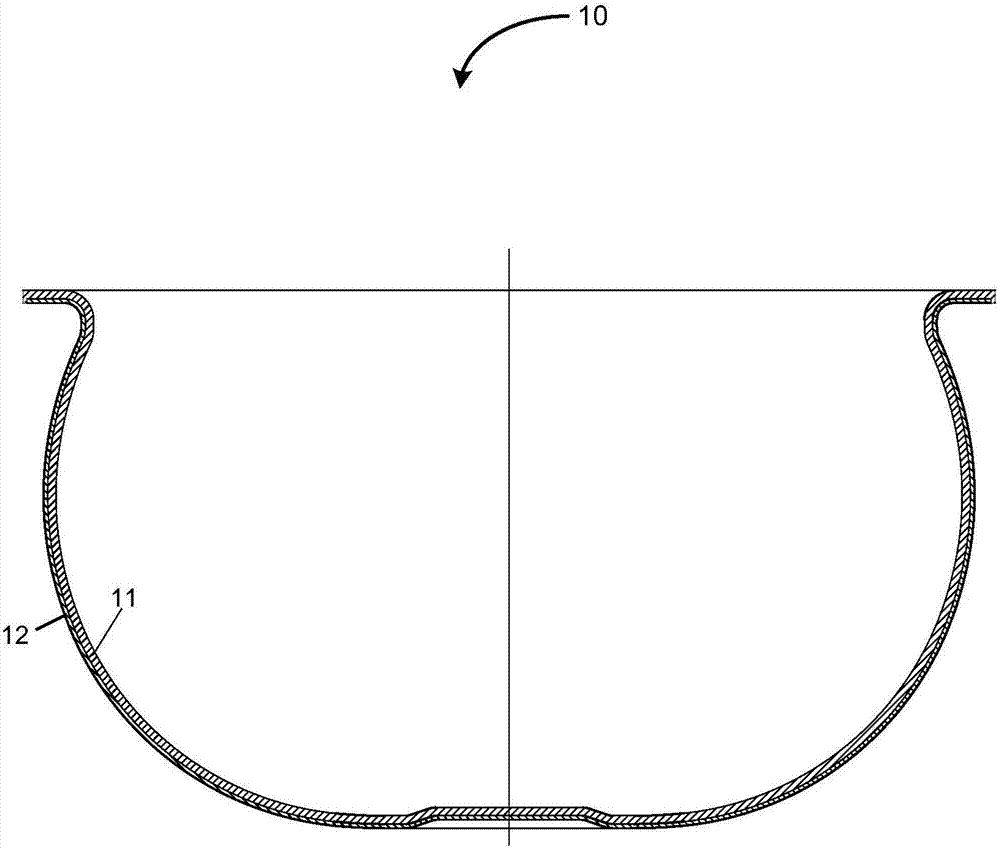

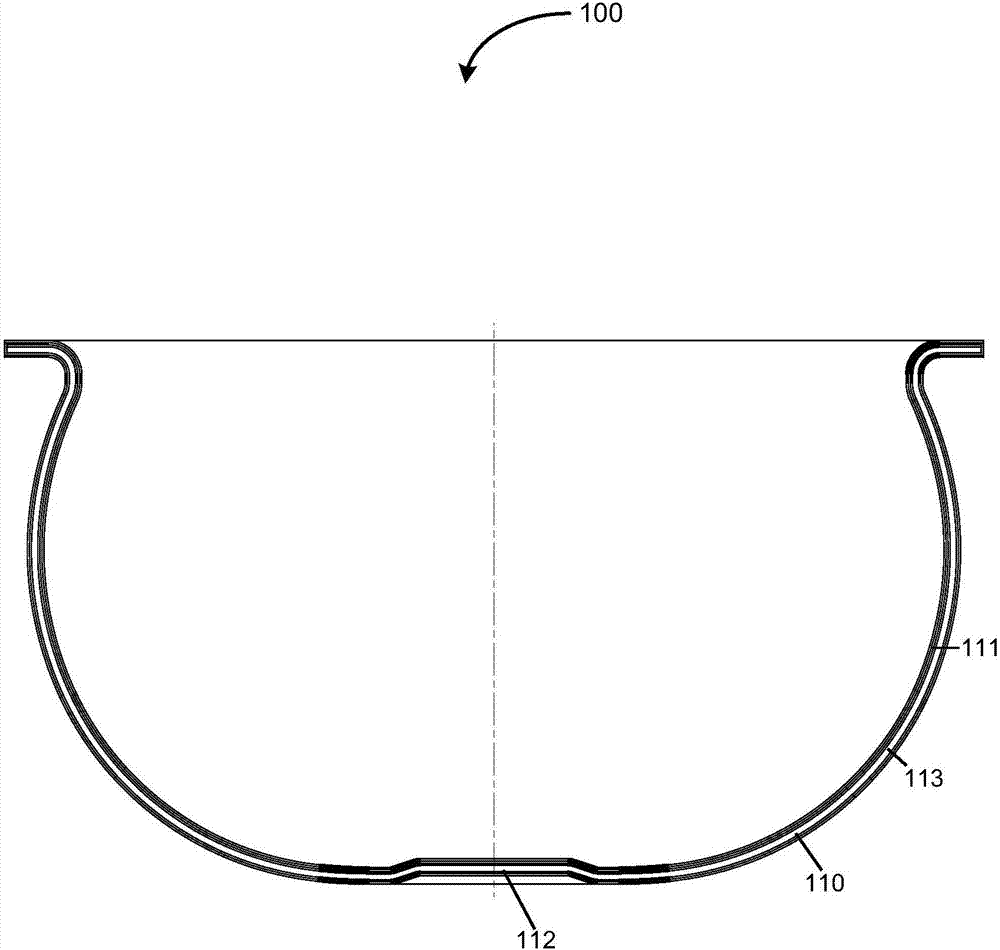

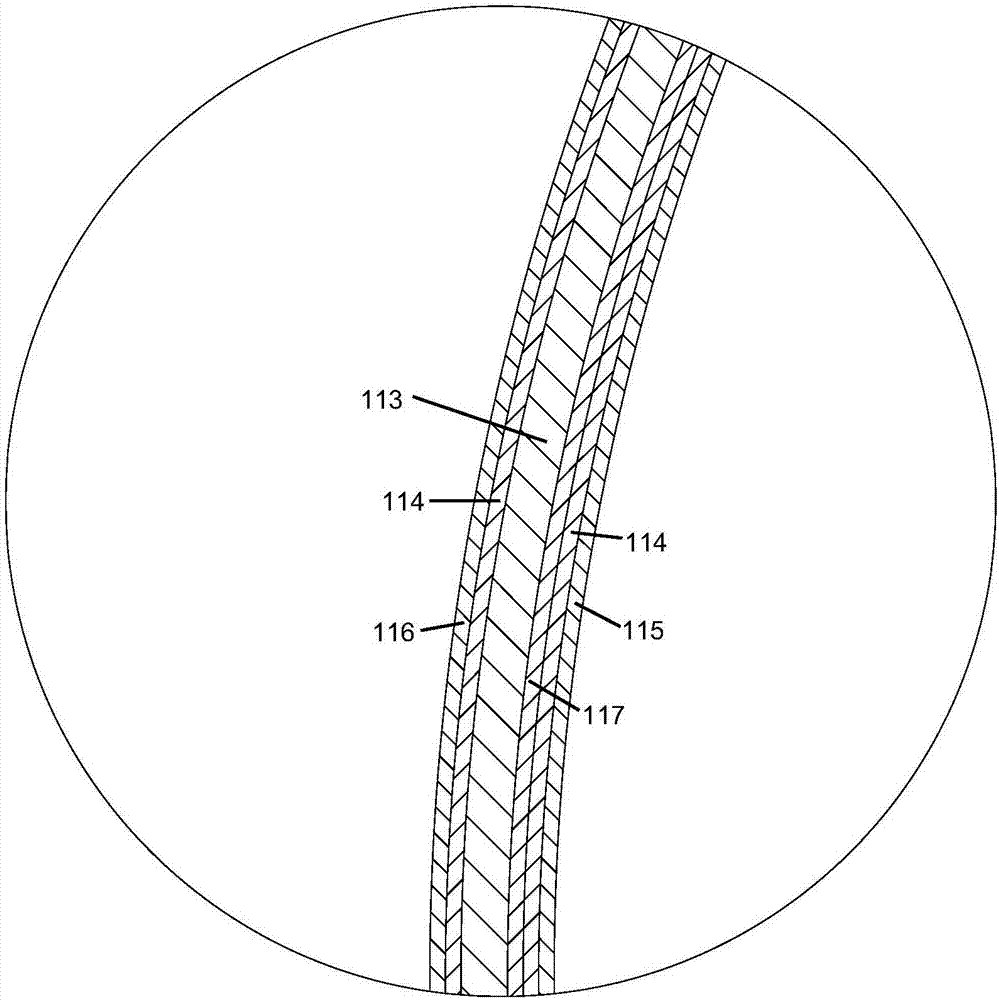

[0027] Below, refer to Figure 2 to Figure 4 A preferred embodiment of the present invention will be described. The inner pot according to the present invention can preferably be applied to cooking utensils heated by means of electromagnetic induction, and of course it can also be applied to cooking utensils heated by eg a heating plate. The cooking appliance according to the present invention ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com