Glass block forming device and forming method thereof

A molding device and molding method technology, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of limited temperature field uniformity, local stress concentration of products, and affecting product quality, etc., to achieve temperature field uniformity The effect of reducing and reducing the heat dissipation speed and improving the qualified rate of molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

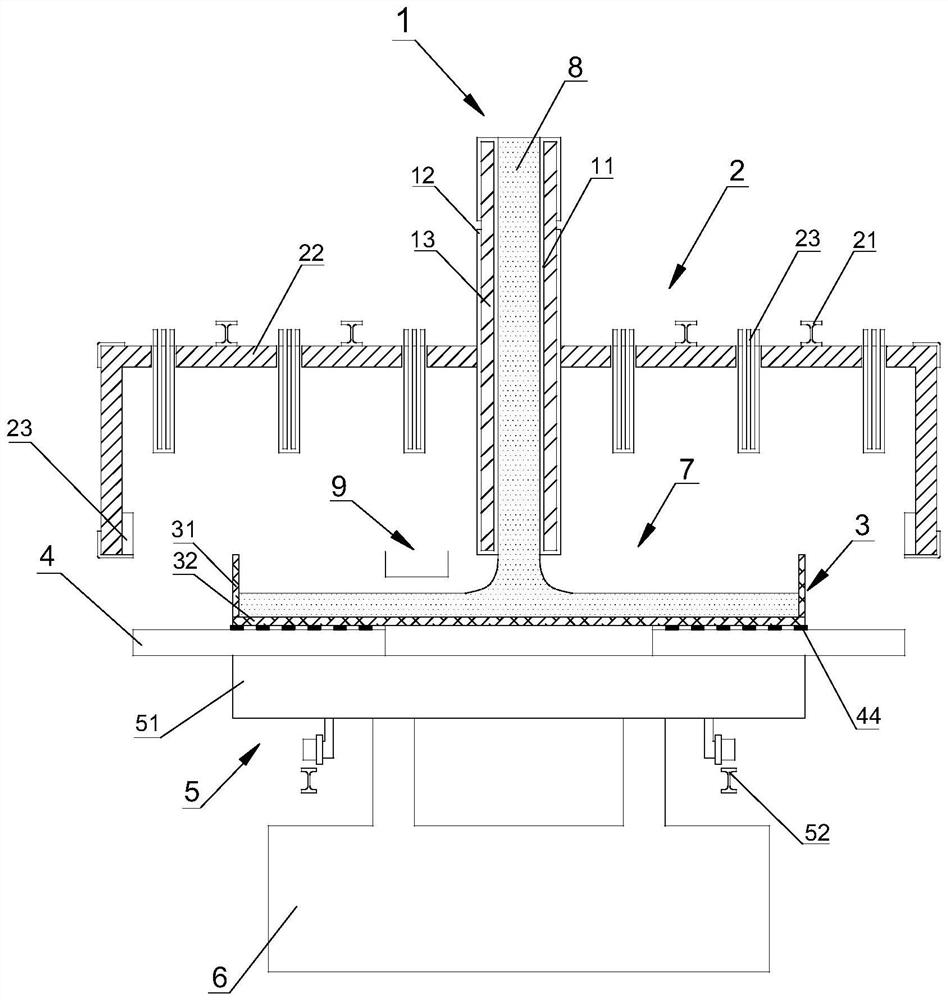

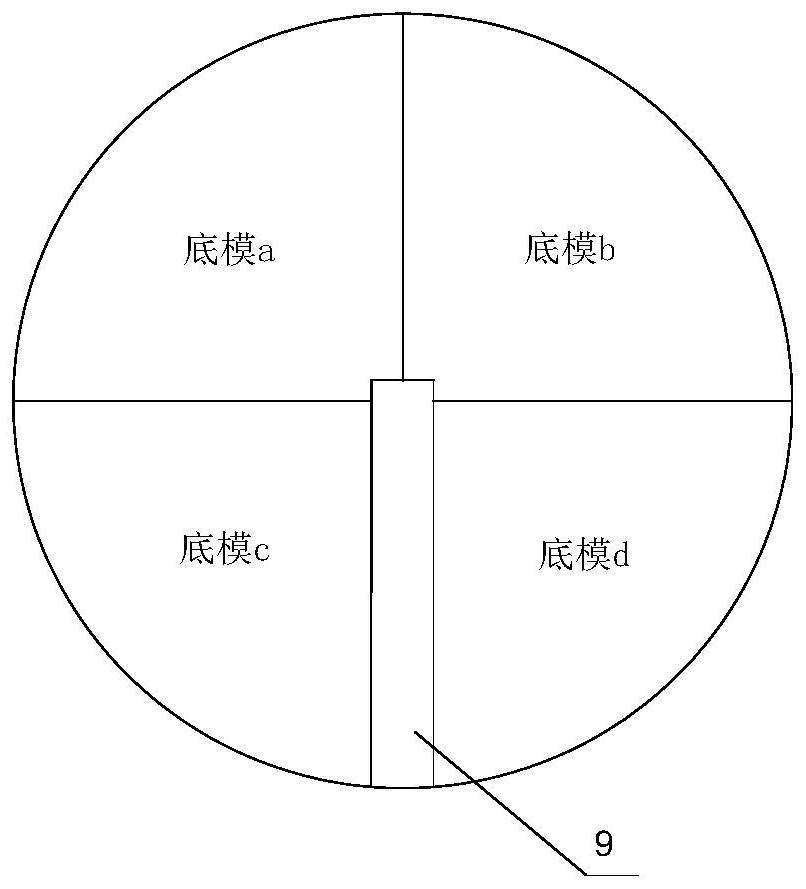

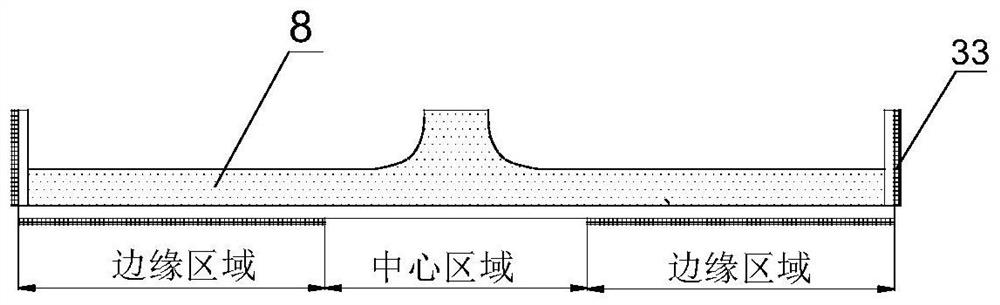

[0034] The glass block forming device of the present invention includes a discharge pipe 1, a soaking cover 2, a forming mold 3, a heat dissipation support 4, a transfer device 5 and a lifting device 6, such as figure 1shown. The discharge pipe 1 passes through the top of the soaking cover through the round hole of the soaking cover and enters the molding space 7 formed by the soaking cover 2 and the forming mold 3. A certain distance; the forming mold 3 is located directly under the soaking cover 2, and the glass liquid flows out from the discharge pipe 1 to complete shaping in the forming space 7; the heat dissipation bracket 4 is placed under the bottom of the forming mold 3 for balanced forming The heat in each area of the lower surface of the bottom mold of the mold 3 is dissipated, and bears the pressure of the forming mold 3 and the formed glass liquid to prevent the glass surface from being subjected to tensile stress and cracks due to the deformation of the forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com