Warm static liquid extrusion method and mould for producing magnesium alloy wire or bar

A technology of hydrostatic extrusion and manufacturing method, applied in metal extrusion dies, metal extrusion control equipment, metal extrusion and other directions, can solve problems such as poor plasticity, high processing cost, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

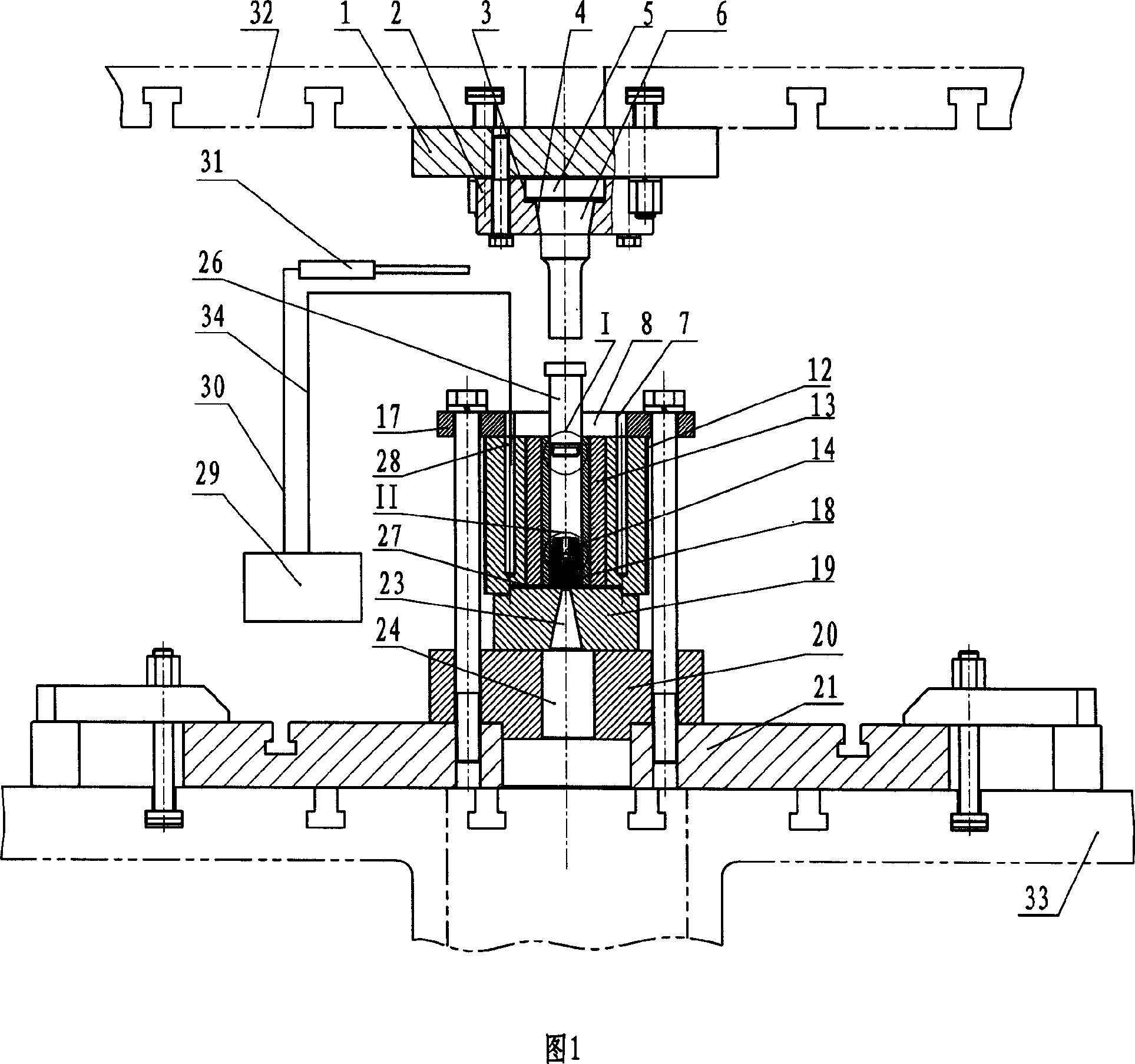

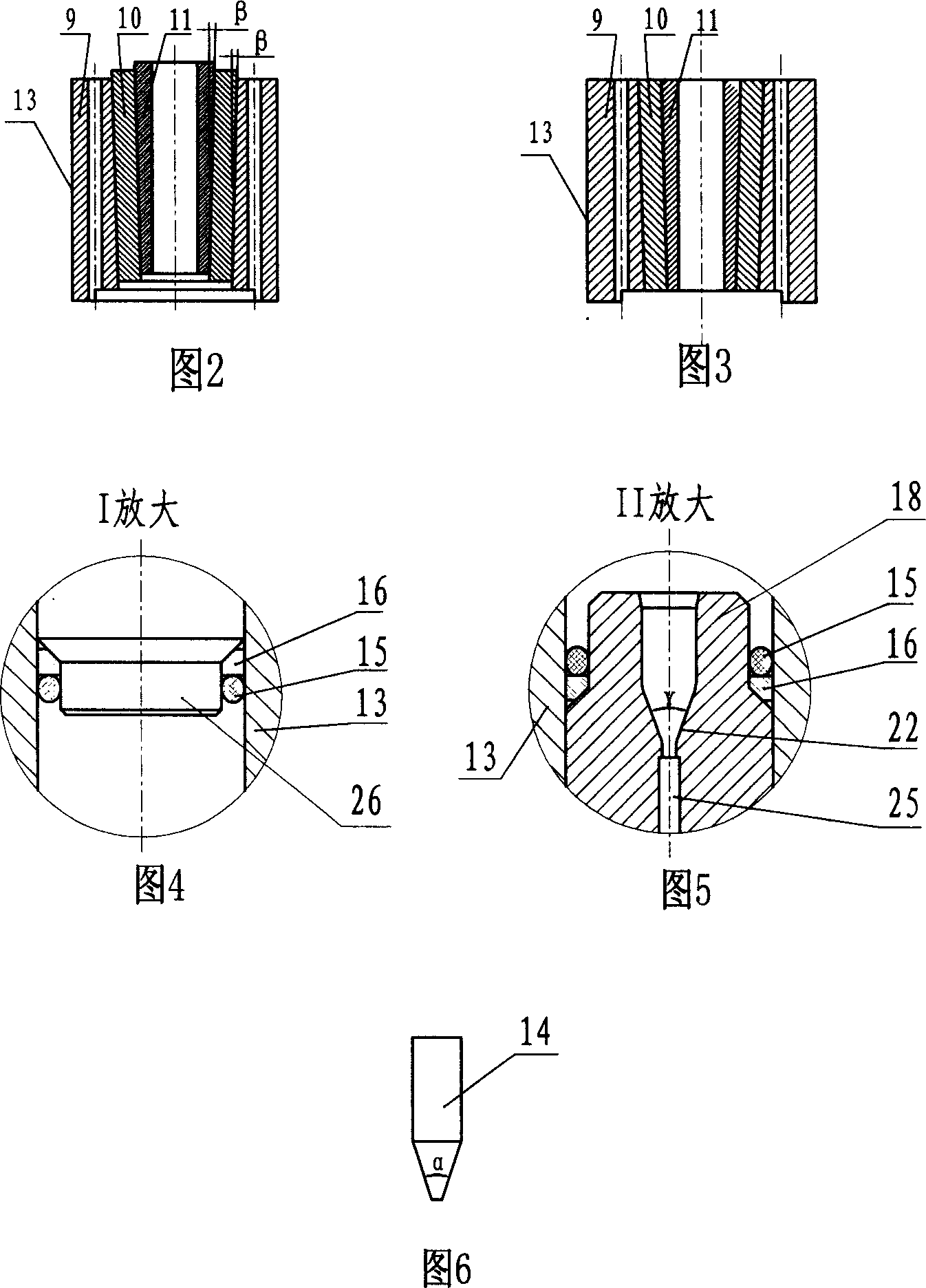

[0009] Specific embodiment one: a kind of magnesium alloy wire or bar material thermostatic extrusion manufacturing method described in this embodiment, it is realized according to the following steps: 1, magnesium alloy billet processing: choose magnesium alloy bar stock, Process the magnesium alloy bar head into a conical surface with a cone angle of 20-60°; 2. Apply lubricant: mix castor oil and graphite in a weight ratio of 3-5:1 and apply it to the processed magnesium alloy blank On the surface; 3. Castor oil heating: preheat the castor oil to 250-300°C; 4. Heating and temperature control of the warm static liquid extrusion die: heat the warm static liquid extrusion die to 250-300°C and control the temperature Between 250 and 300°C; 5. Put the magnesium alloy billet: put the magnesium alloy billet that has completed step 2 into the extrusion die of a warm and static liquid extrusion die with a temperature of 250 to 300°C. The head and the conical surface of the extrusion ...

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the magnesium alloy billet is first heated to 250-300°C, and the heating rate is kept at 6-8°C / min. After reaching the heating temperature, the billet must be heated The furnace is kept warm for at least 15-45 minutes, and then the heated magnesium alloy billet is put into the inner cavity of the extrusion die of the hydrostatic extrusion die. Using such process steps can greatly improve production efficiency.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step one, the magnesium alloy bar head is processed into a conical surface with a cone angle α of 38°, and a cone with a cone angle γ of the extrusion die mouth of 40° The surfaces cooperate to form an effective seal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com