Printed circuit board

A technology for printed circuit boards and power supplies, which is applied to printed circuit parts, printed circuits connected with non-printed electrical components, etc., and can solve the problem of increasing the pin resistance value of the plug-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and preferred embodiment the present invention is described in further detail:

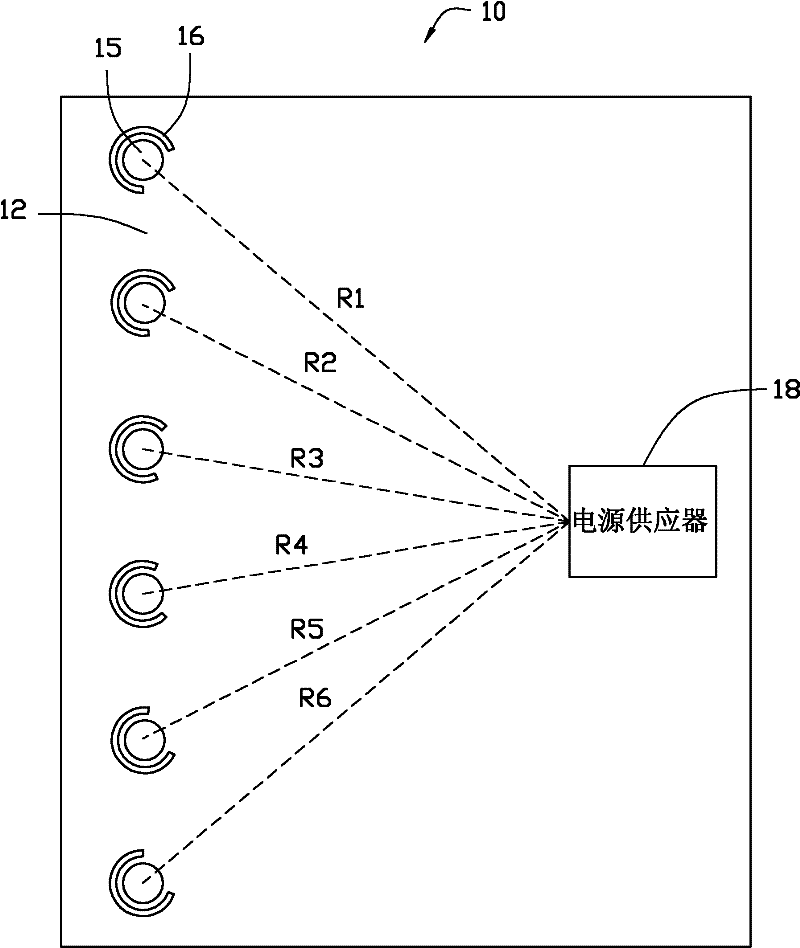

[0016] see figure 2 , the preferred embodiment of the printed circuit board of the present invention includes a power layer 10 and a power supply 18 . The power supply layer 10 is provided with a layer of copper foil 12 , an insertion hole 15 , and a thermal relief 16 . In this embodiment, assuming that the power supply 18 is disposed on the top layer of the entire printed circuit board, the power supply 18 is disposed on the power layer 10 . In other embodiments, the power supply 18 is generally disposed on the top layer or the bottom layer of the entire printed circuit board, and is connected to the power layer 10 and the ground layer through other via holes.

[0017] The copper foil 12 is laid on the surface of the power layer 10 . The plug-in hole 15 runs through the entire printed circuit board, and is used to make the pins of the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com