High-performanceradialorientation rare-earth permanent magnetic tube and thermal-deformationforming method thereof

A rare earth permanent magnet, high-performance technology, applied in the direction of permanent magnets, magnetic materials, magnetic objects, etc., can solve the problems of short rheological process, limited magnetic properties of magnets, uneven structure and properties of magnetic rings, etc., and achieve uniform structure and magnetic properties. Improve performance, reduce plastic deformation resistance, and avoid the effects of micro-cracks at the front end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

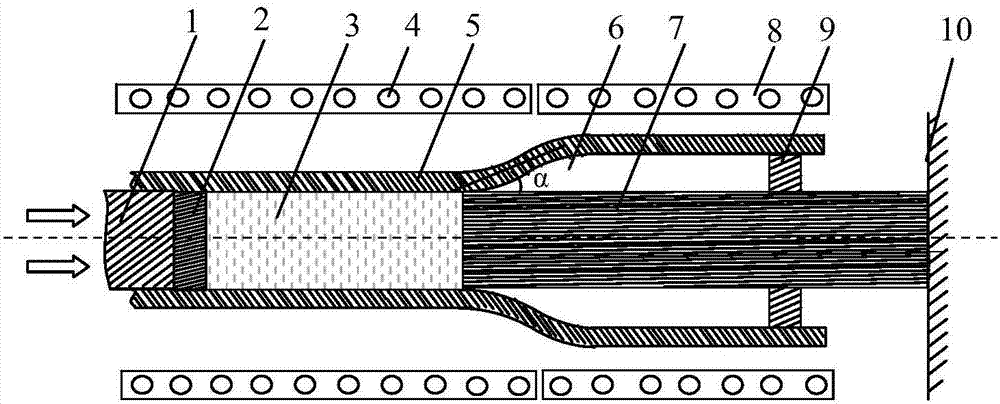

[0043] A high-performance radially oriented rare earth permanent magnet tube, the production steps of which include:

[0044] Put the component mass ratio as Nd 27.94 Fe 65.78 co 3.97 Ga 0.48 B 0.95 Al 0.28 Cu 0.06 The quick-quenched belt is crushed to make isotropic alloy powder, and the magnetic powder with a particle size of 200-300 μm is screened out for future use.

[0045] MoS 2 Soluble in acetone solution, adjust to a suitable concentration, spray on the inner wall of the extrusion cavity with an inner diameter of 40mm, the gasket, the end face and side of the pressure rod and other parts that may be in contact with the magnetic powder, repeat spraying twice after drying, and dry.

[0046] Weigh 700g from the screened magnetic powder, put it into a lubricated mold, cold press and compact, and evacuate until the vacuum degree is higher than 10 -3 Pa, start the extrusion induction coil (4) to heat to 550°C, the hot extrusion ejector rod (1) moves to the right unde...

Embodiment 2

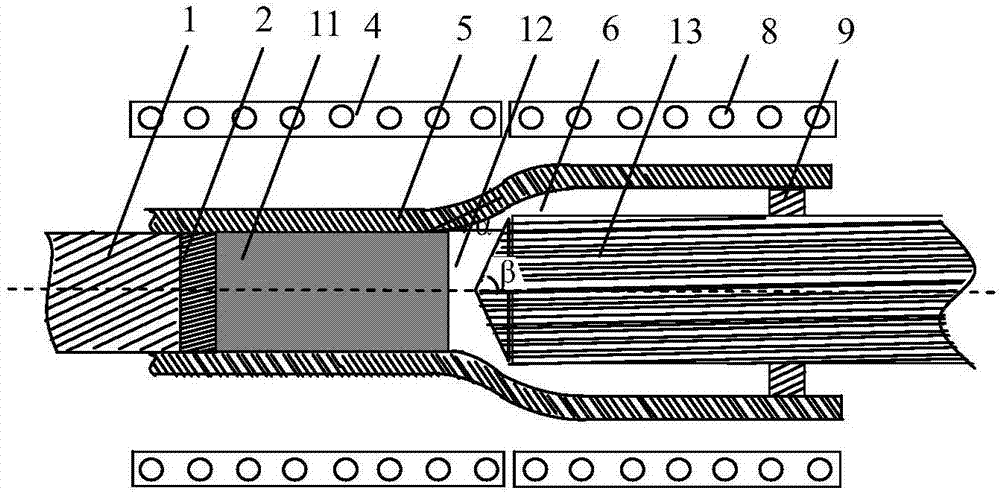

[0051] A high-performance radially oriented rare earth permanent magnet tube, the production steps of which include:

[0052] The component mass ratio is (Nd 0.8 PR 0.2 ) 28.5 Fe 66.16 co 4 Ga 0.42 B 0.92 The quick-quenched belt is crushed to make isotropic alloy powder, and the magnetic powder with a particle size of 200-450 μm is screened out for future use.

[0053] MoS 2 Soluble in acetone solution, adjust to a suitable concentration, spray on the inner wall of the extrusion cavity with an inner diameter of 40mm, the gasket, the end face and side of the pressure rod and other parts that may be in contact with the magnetic powder, repeat spraying twice after drying, and dry.

[0054] Weigh 1650g from the screened magnetic powder, put it into a lubricated mold, cold press and compact, and evacuate until the vacuum degree is higher than 10 -3 Pa, start the extrusion induction coil (4) to heat to 500°C, and heat press between the hot extrusion rods (1) and (7) to form ...

Embodiment 3

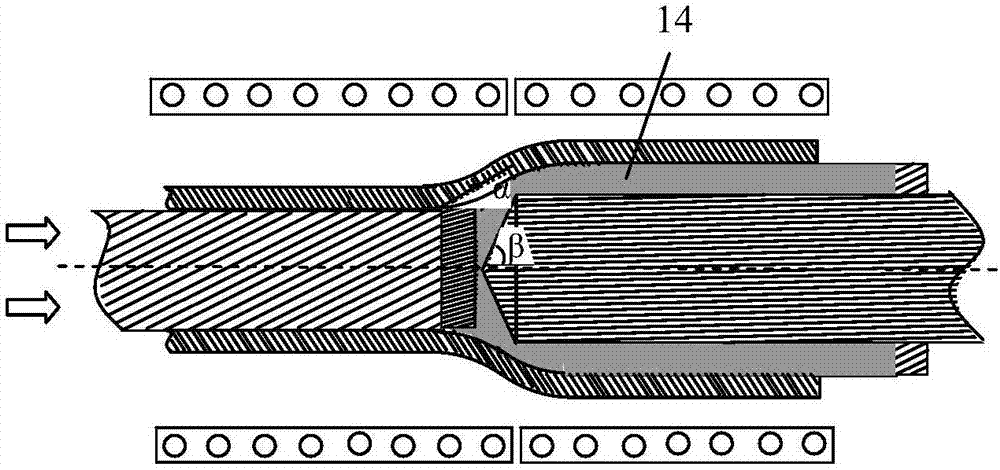

[0059] A high-performance radially oriented rare earth permanent magnet tube, the production steps of which include:

[0060] The component mass ratio is (Nd 0.98 Dy 0.02 ) 28 Fe 67.19 co 3.58 Ga 0.38 B 0.95 The quick-quenched belt is crushed to make isotropic alloy powder, and the magnetic powder with a particle size of 200-450 μm is screened out for future use.

[0061] MoS 2 Soluble in acetone solution, adjust to an appropriate concentration, spray on the parts that may be in contact with the magnetic powder, such as the inner wall of the mold, the gasket, the cross section and the side of the pressure rod, etc. After drying, repeat the spraying twice and dry.

[0062] Weigh 6500g from the screened magnetic powder, put it into a mold with a lubricated extrusion cavity with an inner diameter of 70mm, cold press and compact, and evacuate until the vacuum degree is higher than 10 -3 Pa, start the billet induction heating coil (4) to heat to 600°C, pressure 450MPa, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com