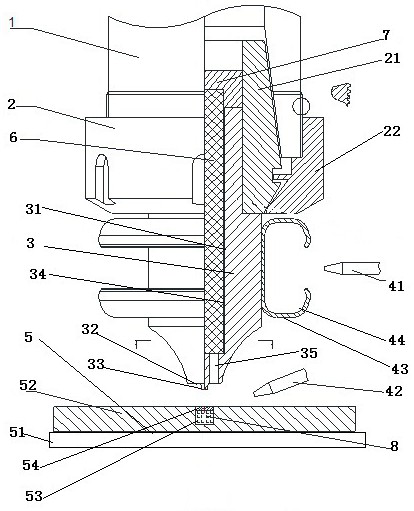

Magnetization-degree-adjustable center magnet-embedded type friction stir welding device

A friction stir and welding device technology, which is applied in the field of metal welding processing, can solve the problems of adding welding auxiliary devices, poor electromagnetic collection effect, unsafety, etc., and achieve the effects of improving weld quality, low cost, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

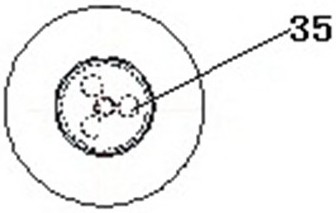

[0041] More preferred embodiment 2: the shaft shoulder 32 is provided with a downward hole structure, which is an oval hole, an elongated hole or other structures with different depths, and other structures are the same as in embodiment 1.

[0042] The main operation steps of the magnetization adjustable center embedded magnetic friction stir welding device:

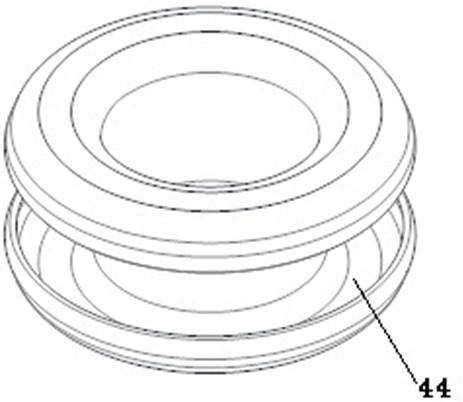

[0043] SP1: first put the cooling cover 43 on the side of the cylinder with the largest outer diameter of the magnetic stirring head 3, and then fix the two by spot welding;

[0044] SP2: Fill the prepared cylindrical strong magnet 6 into the hollow cavity of the stirring head 3, and then set the embedded concave-convex contact surface 71 of the end cover 7 made of stainless steel magnetic shielding material on the clamping of the stirring head 3 department;

[0045] SP3: Put the mixing head prepared by SP2 into the hollow cavity of the motor spindle equipped with clamping device 2, clamp and fix it by ER chuck and ER n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com