High-frequency pulse current and shot blasting compounding metal surface strengthening device and method

A metal surface strengthening, high-frequency pulse current technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems that shot peening cannot reach deeper into the material, it is difficult to form a plastic deformation layer, and hinder the plastic deformation of the surface layer, etc., to achieve performance Excellent, thicker surface strengthening layer, improved fatigue resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

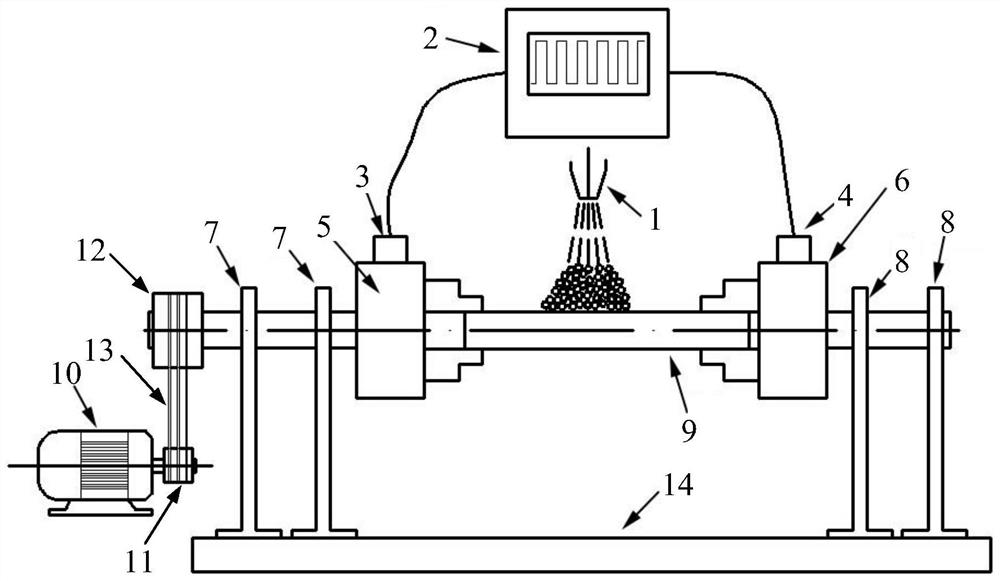

[0036] Such as figure 1 As shown, this embodiment provides a metal surface strengthening device combining high-frequency pulse current and shot peening, which includes a rotating mechanism, a nozzle 1, a pulse power supply 2, a first brush 3, a second brush 4, a first A chuck 5 , a second chuck 6 , a first support seat 7 and a second support seat 8 .

[0037] The centerlines of the first chuck 5 and the second chuck 6 are on the same horizontal line and the centers are opposite, and are used to install a workpiece 9, which is a titanium alloy material, and it is installed on the first chuck 5 and the second chuck 6 Between, the chuck shaft of the first chuck 5 is rotatably connected with the first support base 7, and is driven to rotate by the rotating mechanism, the chuck shaft of the second chuck 6 is rotatably connected with the second support base 8, and the first support base The connection between 7 and the chuck shaft of the first chuck 5, and the connection between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com