Electro-plastic open die forging device and method

An electroplasticity and brush device technology, which is applied in the field of forging, can solve the problems of hindering dislocation movement, reducing strength and hardness, and poor uniformity of annealing, so as to ensure uniformity and reduce plastic deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

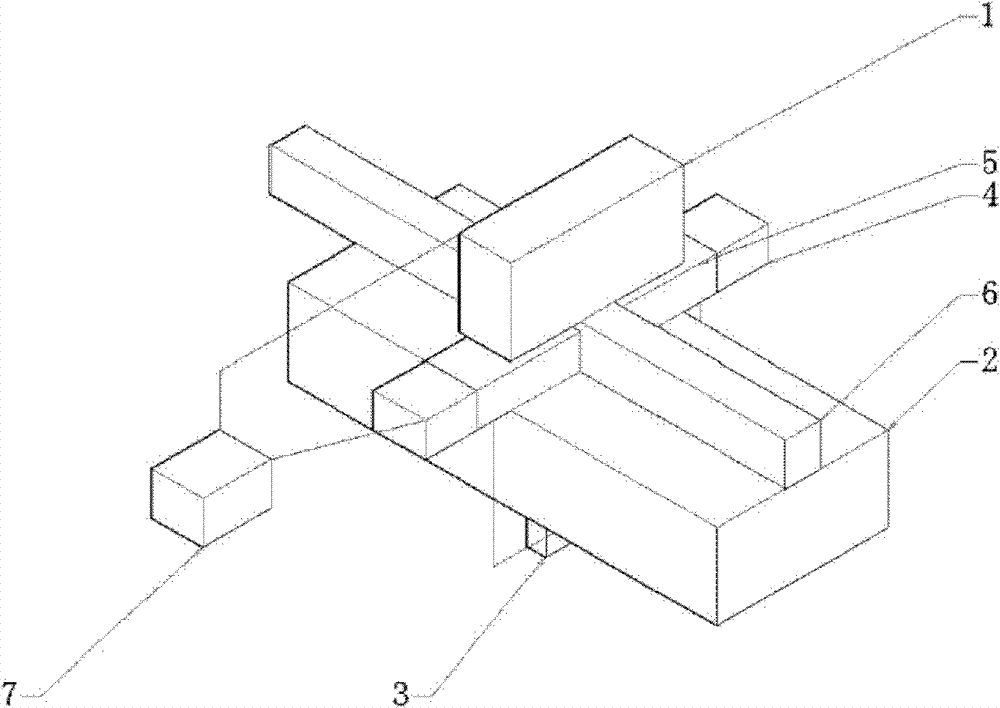

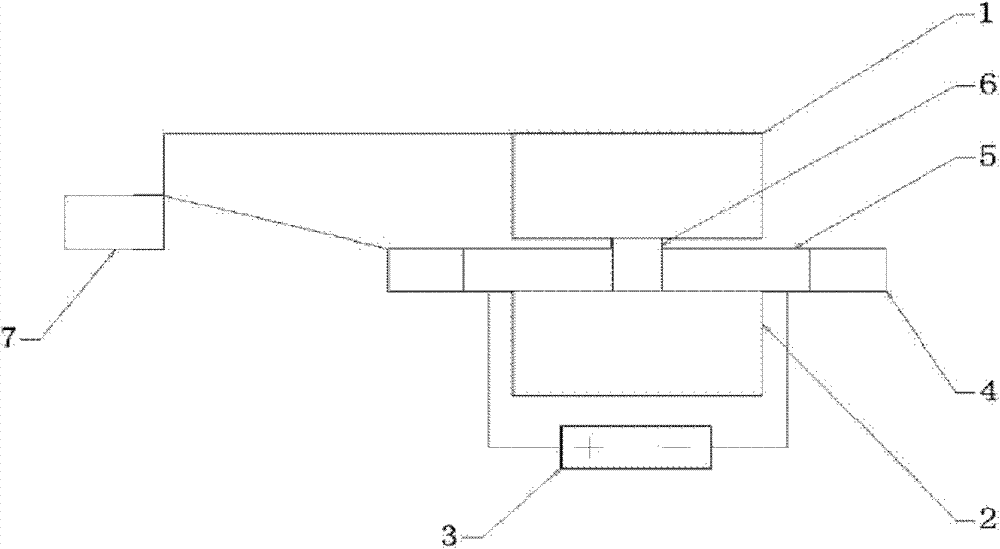

[0024] Such as figure 1 As shown, the present embodiment includes: an upper anvil 1, a lower anvil 2, a pulse power supply 3, a driving device 4, a brush device 5, a blank 6 and a control device 7, wherein: the lower anvil 2 is the same as the upper anvil 1 in width, It is larger than the upper cutting board 1 in length, which is equivalent to a large platform. The movable brush device 5 works on the lower cutting board 2. The pulse power supply 3 is connected with the brush device 5. The driving device 4 drives the brush 5 to reciprocate. The device 5 is placed symmetrically with respect to the blank 6 during the electrification process, and the control device 7 controls the time when the brush device 5 contacts the blank 6 and leaves the blank 6 by detecting the position of the upper anvil 1 according to preset parameters.

[0025] The billet to be processed in this embodiment is a billet made of HRB335, and its specification is 150×150×3000mm. The process parameters of the ...

Embodiment 2

[0028] The blank to be processed in this embodiment is a rectangular blank made of Q235, and its specification is 180×275×5000mm. The process parameters of the continuous pulse power output pulse current are: peak current 7500A, frequency 300HZ, pulse width 60μs, duty cycle 10 %.

[0029] This embodiment is the same as other implementations of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com