Cylindrical accessory machining method and system for metal mold

A metal mold and cylindrical technology, applied in the field of processing method and system of cylindrical accessories, can solve the problems of poor service performance, long production cycle, high production cost, etc., and achieve enhanced plastic deformation ability, enhanced thickness of reinforced layer, and reduced hardening degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

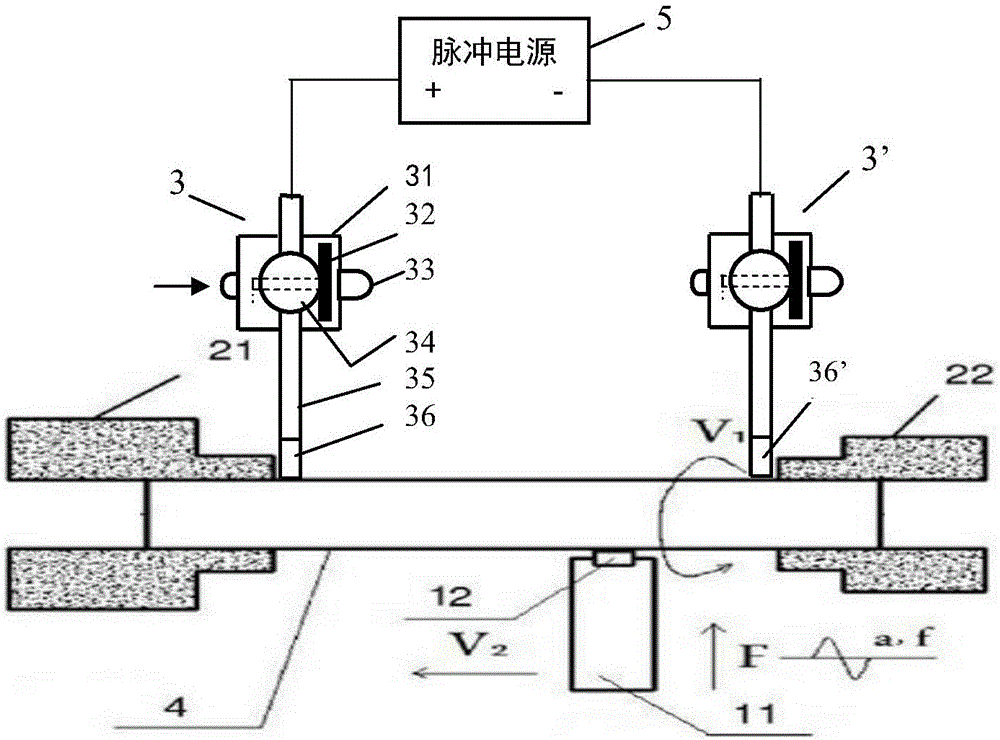

[0032] Attached below figure 1 and embodiments to further illustrate the present invention.

[0033] refer to figure 1 , The processing system of cylindrical accessories for metal molds of the present invention is refitted from a lathe. The system includes:

[0034]Lathe, this lathe comprises main shaft (not shown in the figure), is installed on the main chuck 21 of this main shaft, tail stock (not shown in the figure) and small slide plate (not shown in the figure) etc.; The driven shaft (not shown) on the tailstock, the center line of the driven shaft coincides with the center line of the main shaft; the secondary chuck 22 installed at one end of the driven shaft, the secondary chuck and The main chuck is used to clamp a cylindrical accessory 4; the first brush device 3 and the second brush device 3' positioned by magnetic force are insulated and installed on the bed of the lathe; the pulse power supply 5, one The output terminal (+ terminal) is directly connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com