Patents

Literature

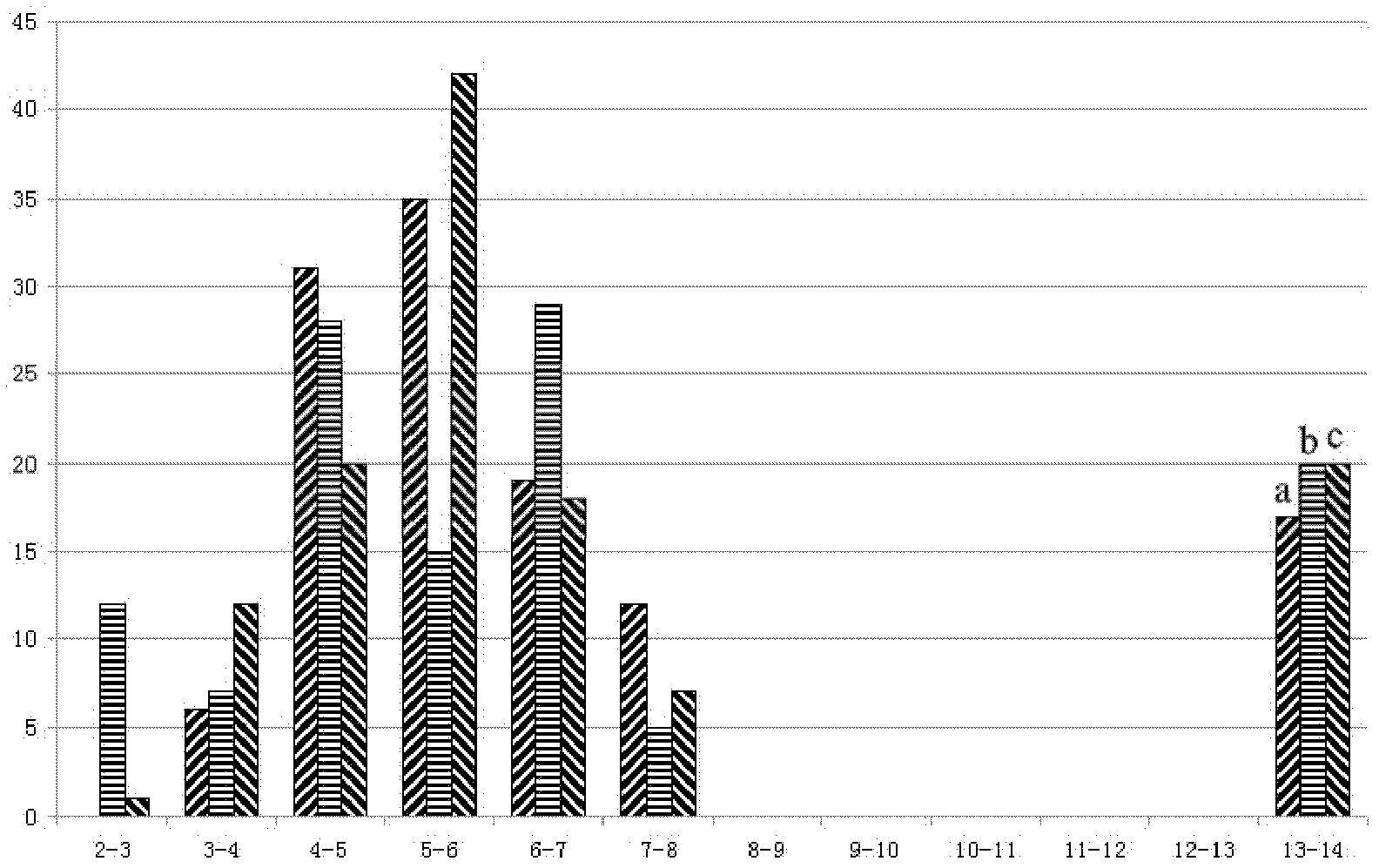

30results about How to "Accurate energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

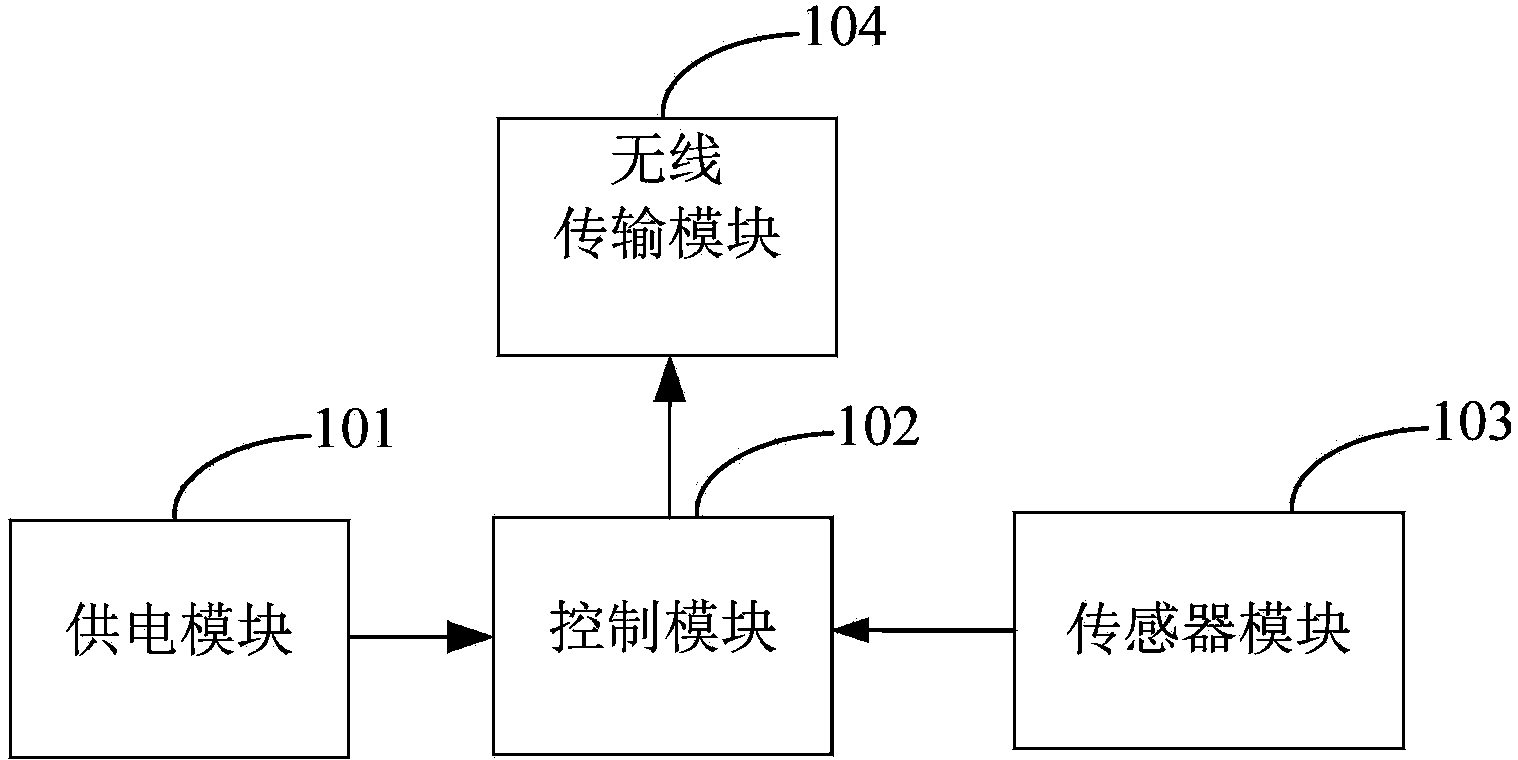

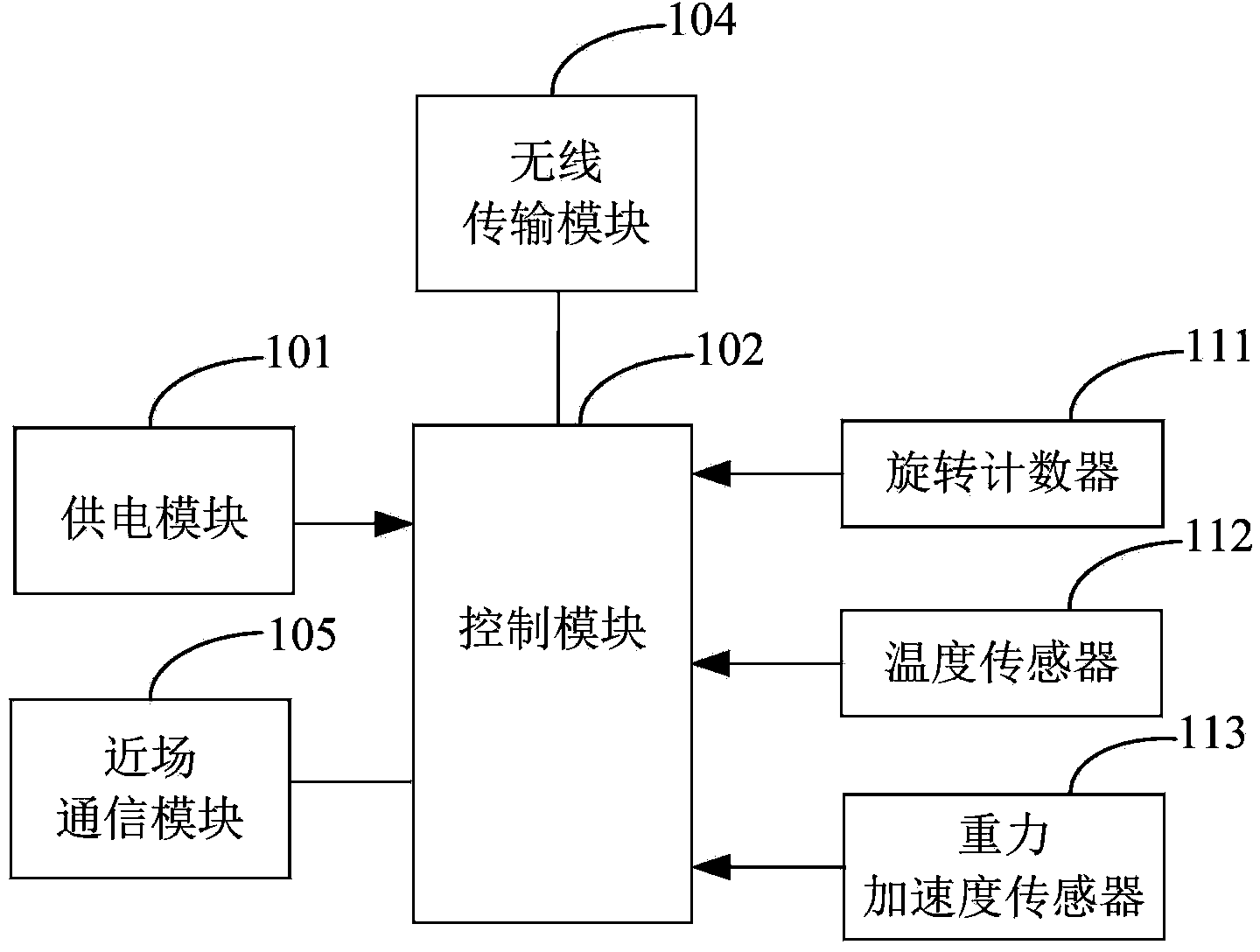

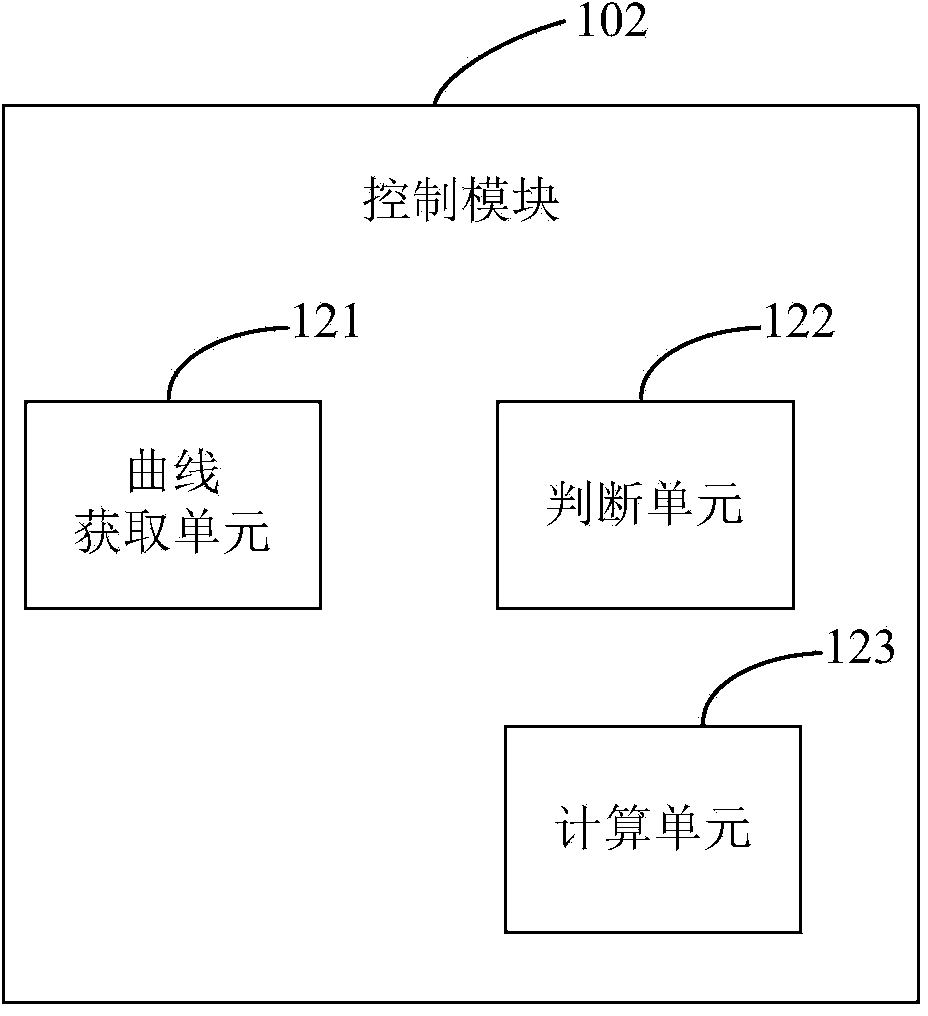

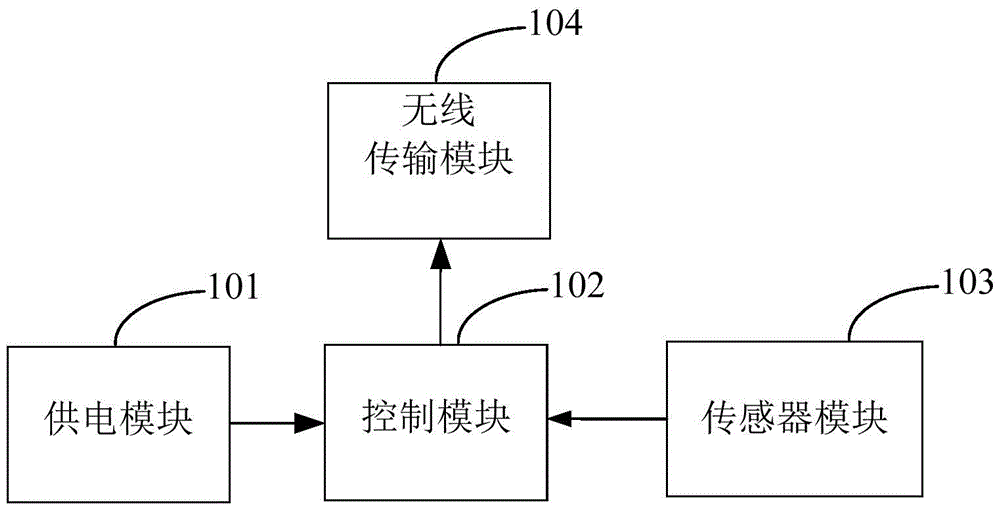

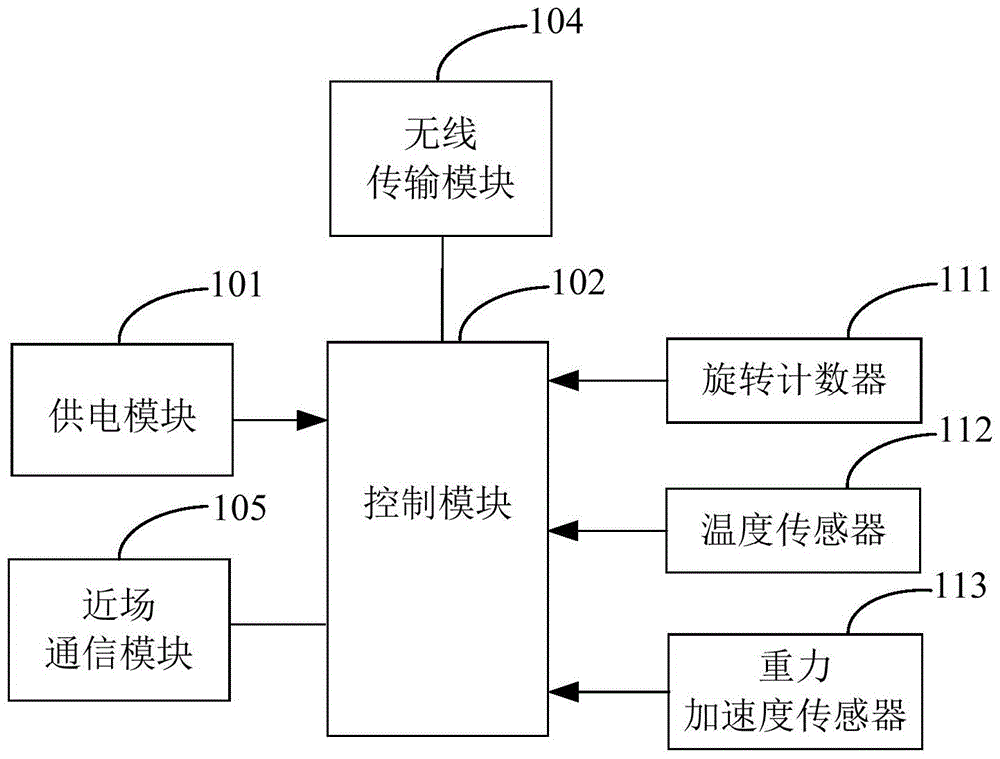

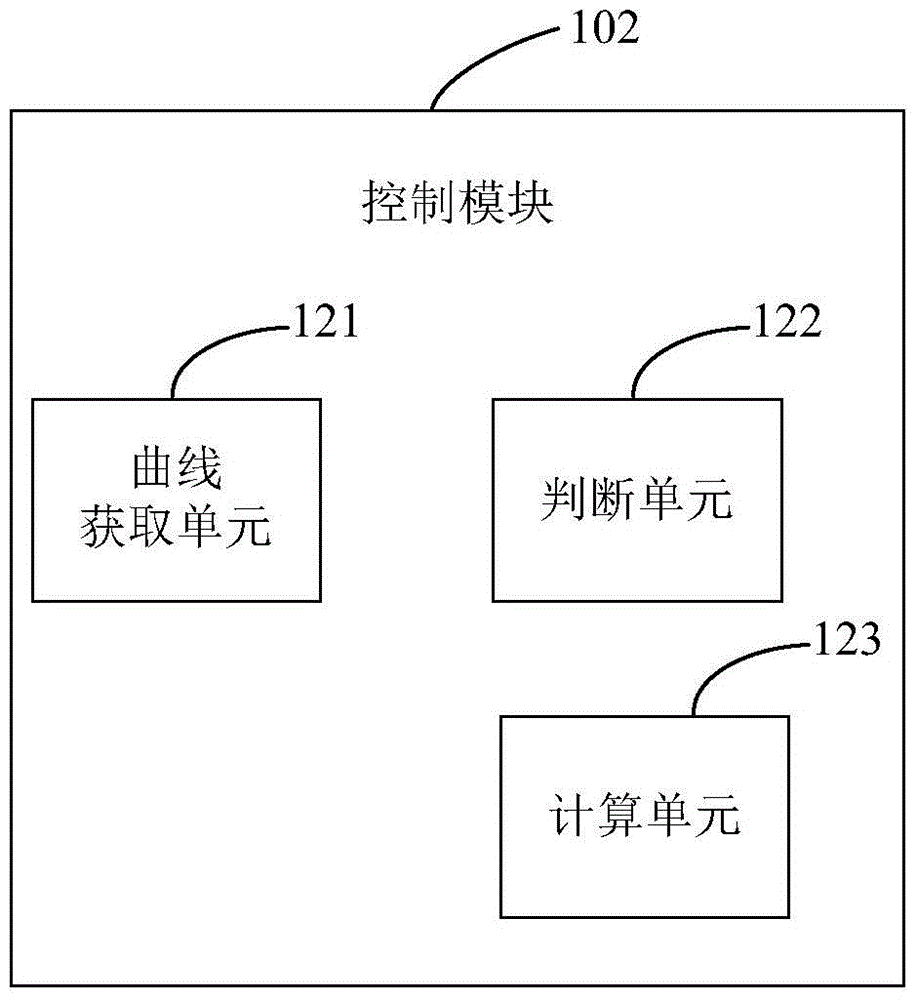

Intelligent skipping rope and control method

ActiveCN103801048AAccurate amount of exerciseAccurate energy consumptionSkipping-ropesWireless transmissionManufacturing technology

The invention is suitable for the technical field of sports equipment manufacturing, and provides an intelligent skipping rope. The intelligent skipping rope comprises a handle and a rope body, and a control module, a sensor module, a wireless transmission module and a power supply module are further arranged inside the handle; the output end of the power supply module is connected with the input end of the control module; the output end of the sensor module is connected with the input end of the control module; the output end of the control module is connected with the input end of the wireless transmission module, and the control module is used for obtaining a motion curve according to motion parameters collected by the sensor module, obtaining motion consumed energy values according to the motion curve, and sending the motion parameters and the motion consumed energy values to an intelligent terminal through the wireless transmission module. According to the intelligent skipping rope, a more accurate algorithm different from a traditional mode is adopted for calculating calories, and the accurate amount of motion and accurate energy consumption can be accurately worked out in various motion modes.

Owner:SHENZHEN DO INTELLIGENT TECH CO LTD

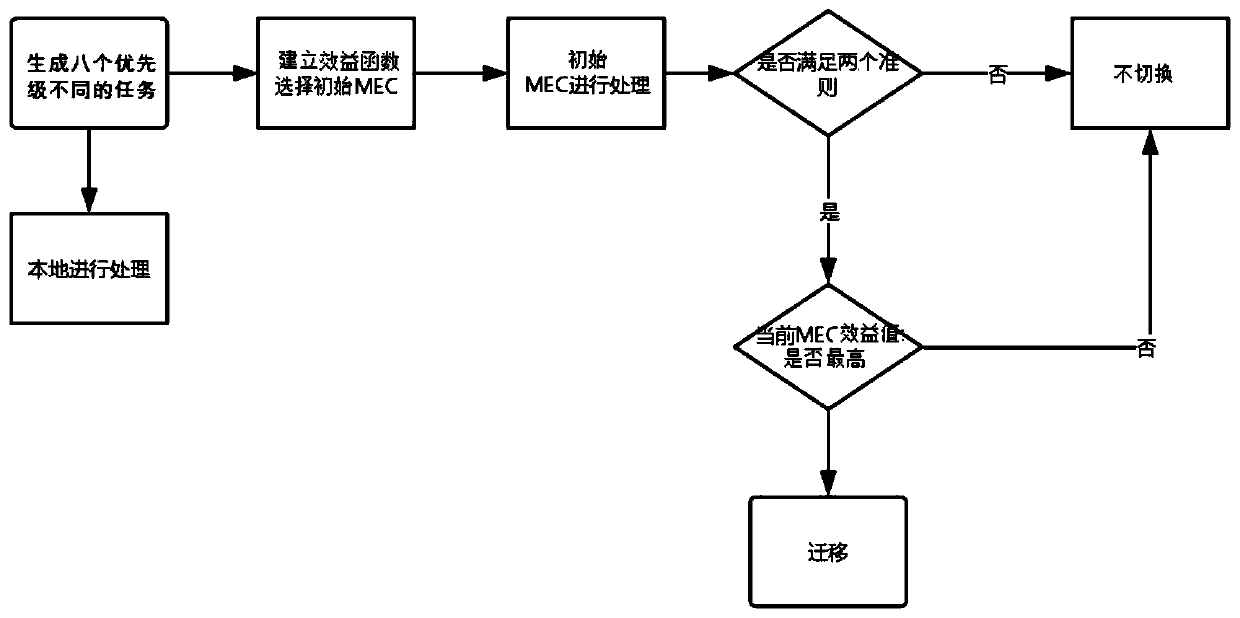

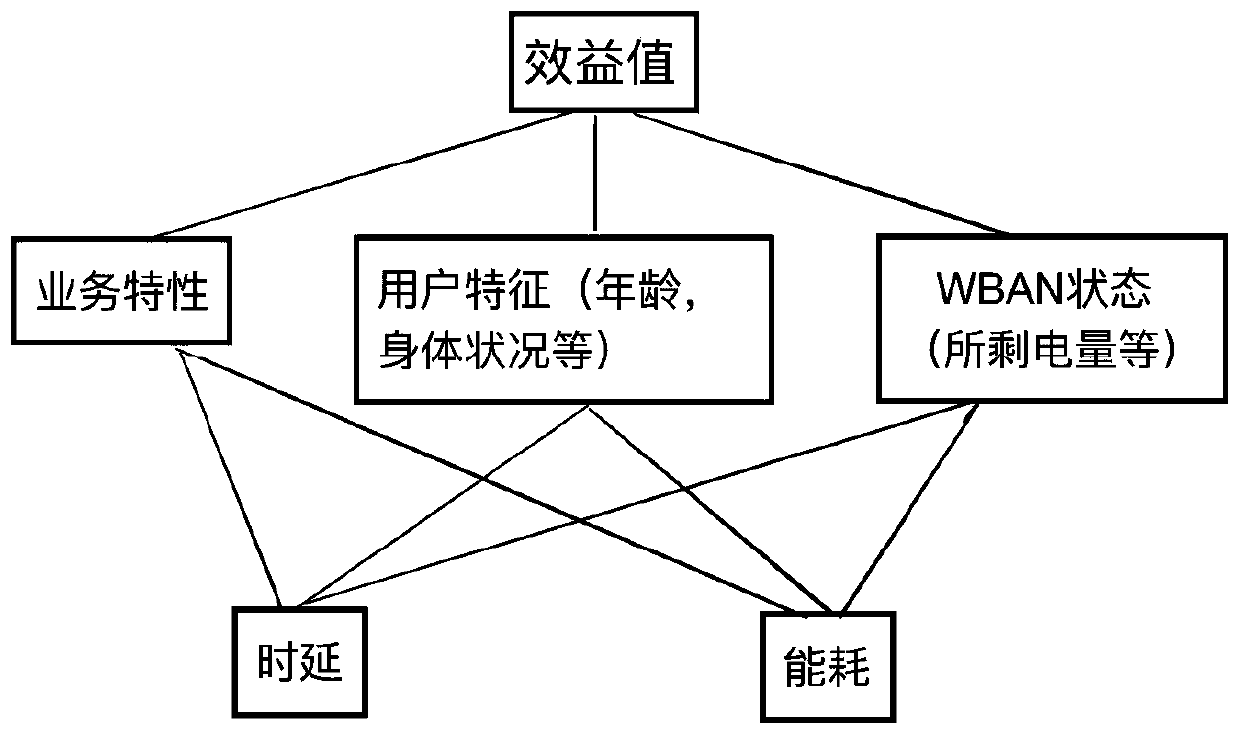

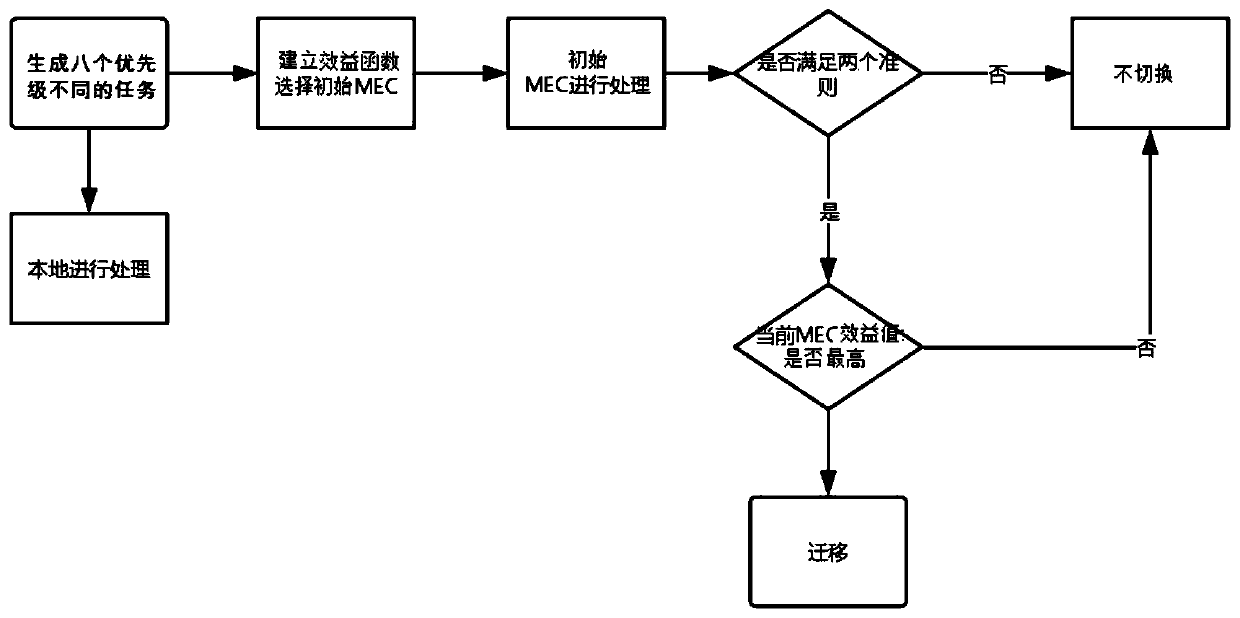

Mobile unloading migration algorithm based on improved HRRN algorithm and multi-attribute decision

ActiveCN111132235ARelieve computing pressureImprove processing speedNetwork traffic/resource managementEdge serverBody area network

The invention relates to a mobile unloading migration algorithm based on an improved HRRN (High Resolution Response Next) algorithm and a multi-attribute decision. The method comprises the following steps: step 1, a single wireless body area network generates a plurality of tasks with different priorities at a certain moment, if the tasks can be locally processed, the tasks are directly locally processed, otherwise, the tasks are uploaded to an edge server; 2, establishing a benefit function of an edge server, and taking the edge server with a high benefit value as an initial edge server of the current task; 3, judging whether the current edge server is suitable or not; 4, judging whether the edge server meets two criteria or not, wherein one of the criteria can be used as a candidate edgeserver; and step 5, according to the benefit function of the edge server established in the step 2, calculating the benefit values of all candidate edge servers, and selecting the edge server with the highest benefit value to migrate.

Owner:东北大学秦皇岛分校

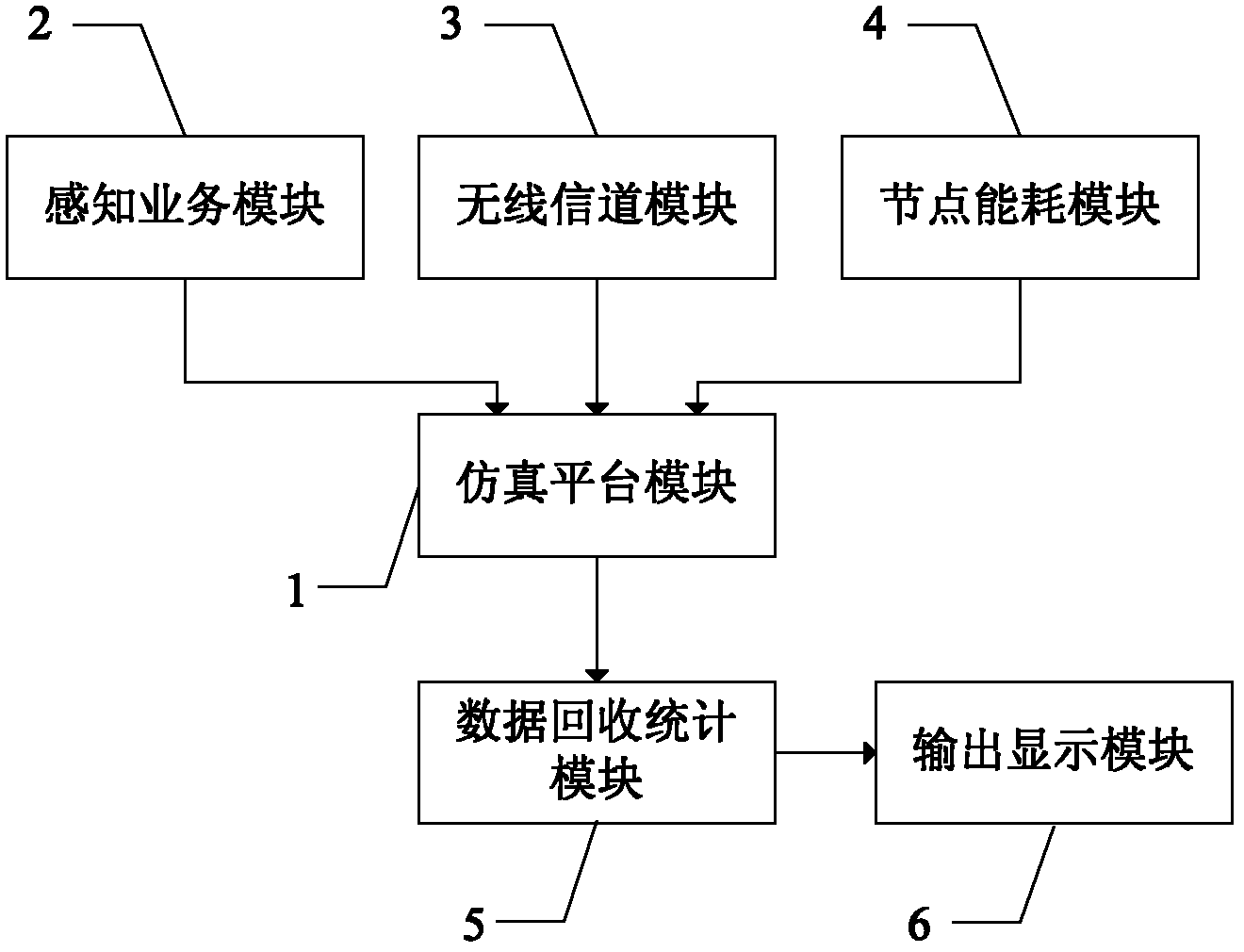

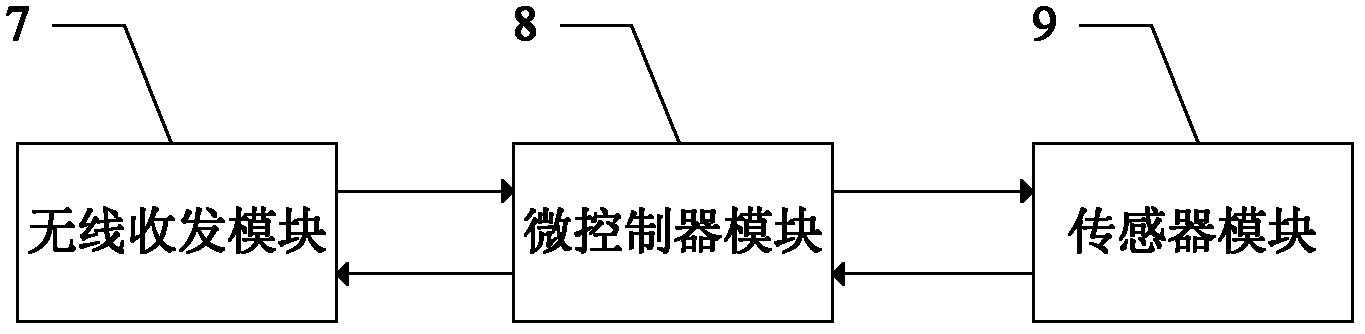

Energy consumption simulation tool of wireless sensor network and simulation method thereof

ActiveCN102546063AAccurate energy consumptionEnergy efficient ICTNetwork topologiesLine sensorService model

The invention provides an energy consumption simulation tool of a wireless sensor network and a simulation method thereof, belonging to the field of the wireless sensor network, aiming to solve the problem that the conventional wireless sensor network cannot accurately respond the energy consumption condition of a sensor node. The energy consumption simulation tool of the wireless sensor network comprises a simulation platform module, a sensing service module, a wireless channel module and a node energy consumption module. The network energy consumption simulation method based on the simulation tool comprises the following steps: an initializing process: setting a radio propagation condition on the simulation platform module, and selecting a corresponding wireless channel model on the wireless channel module; setting sensing services on the simulation platform module, and establishing a sensing service model; setting node working energy consumption information by the node energy consumption module; and a simulation process: starting the simulation process by the simulation platform module, operating the sensing service model by the sensing service module, sending the sensing service information to the node energy consumption module to simulate a node to execute service energy consumption, and counting node energy consumption by the simulation platform module so as to obtain energy consumption of the wireless network. The energy consumption simulation tool of the wireless sensor network and the simulation method thereof are used for the wireless sensor network.

Owner:哈尔滨工大正元信息技术有限公司

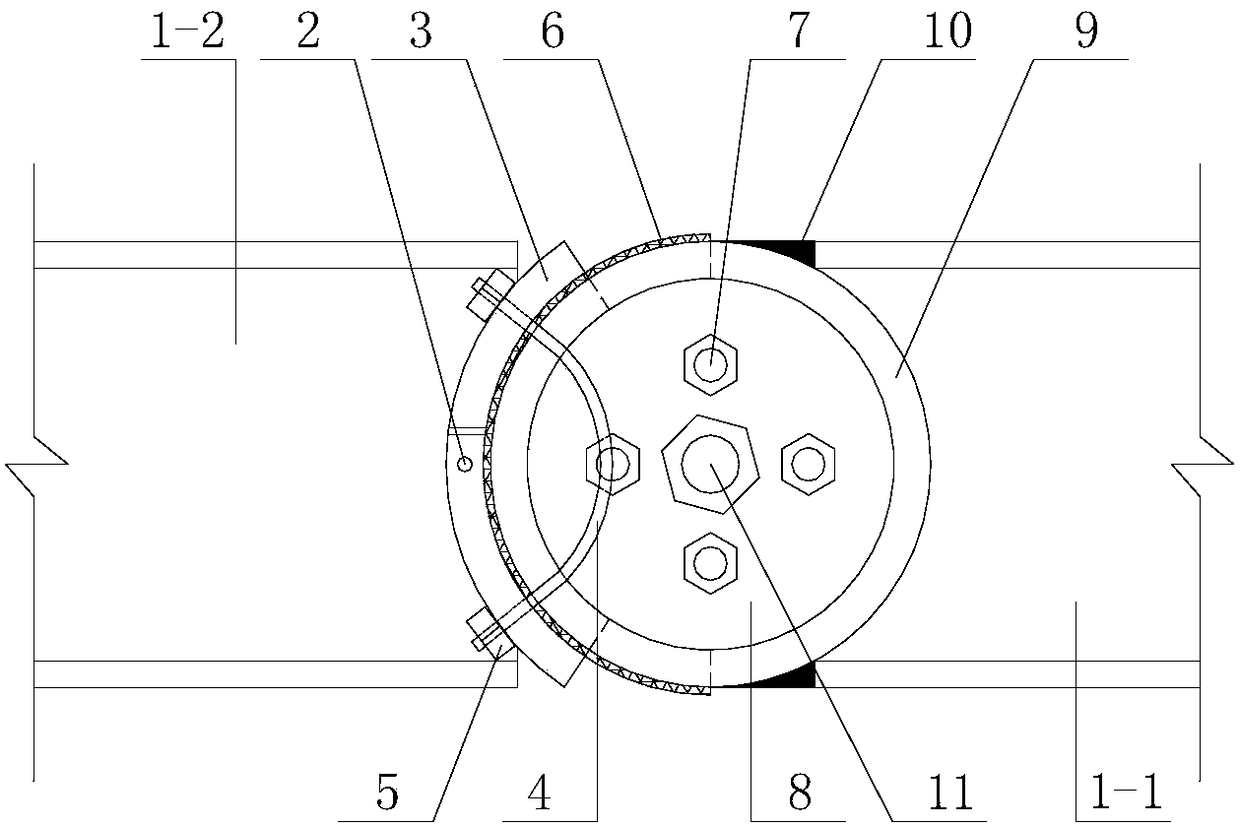

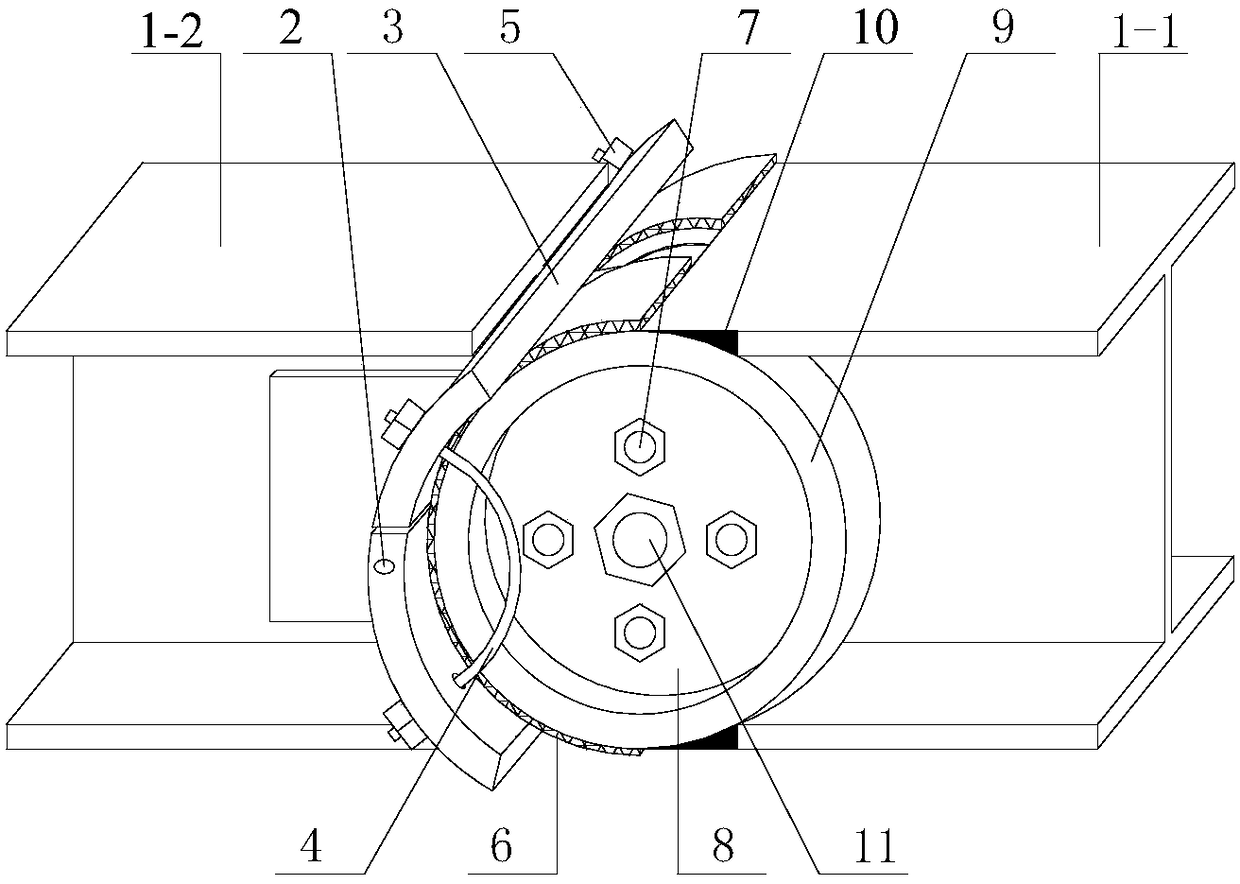

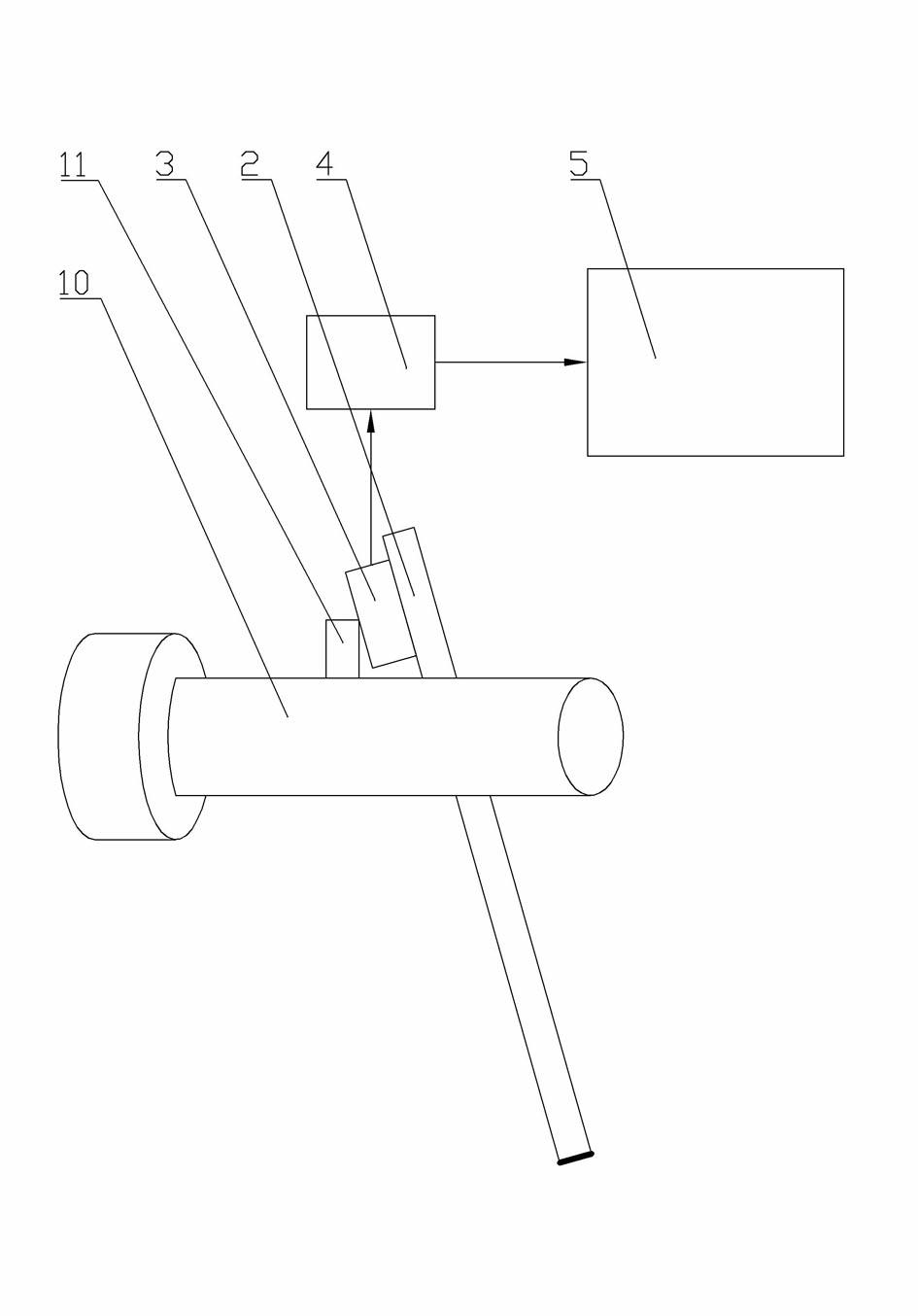

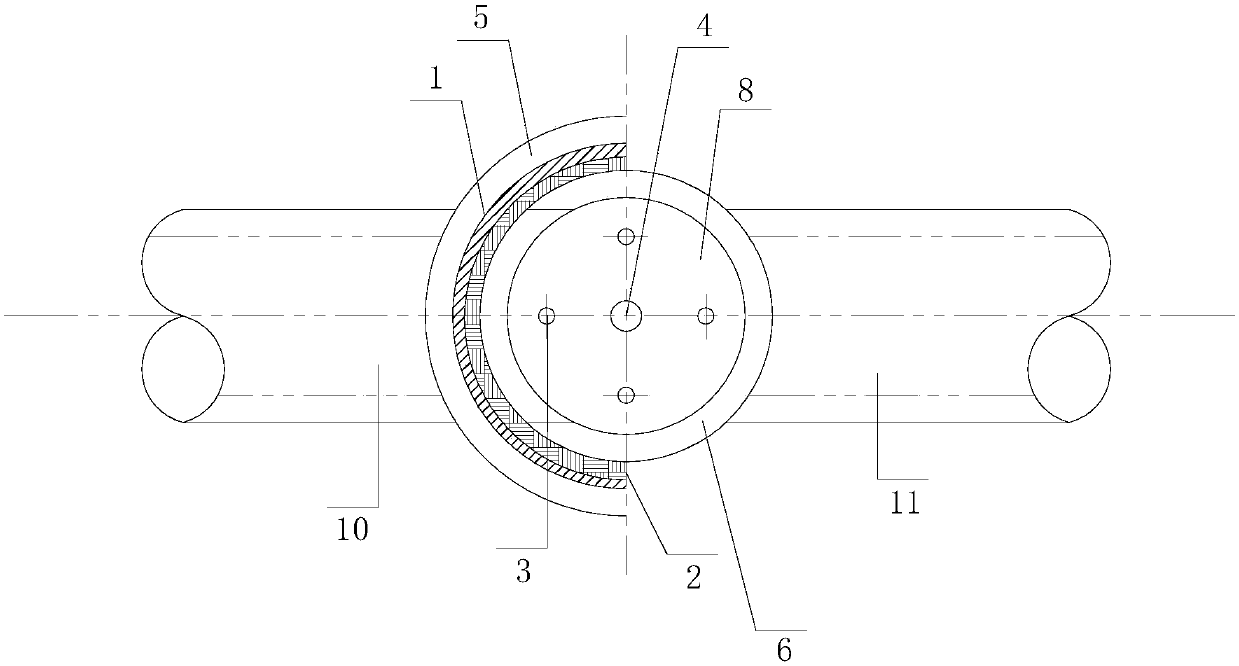

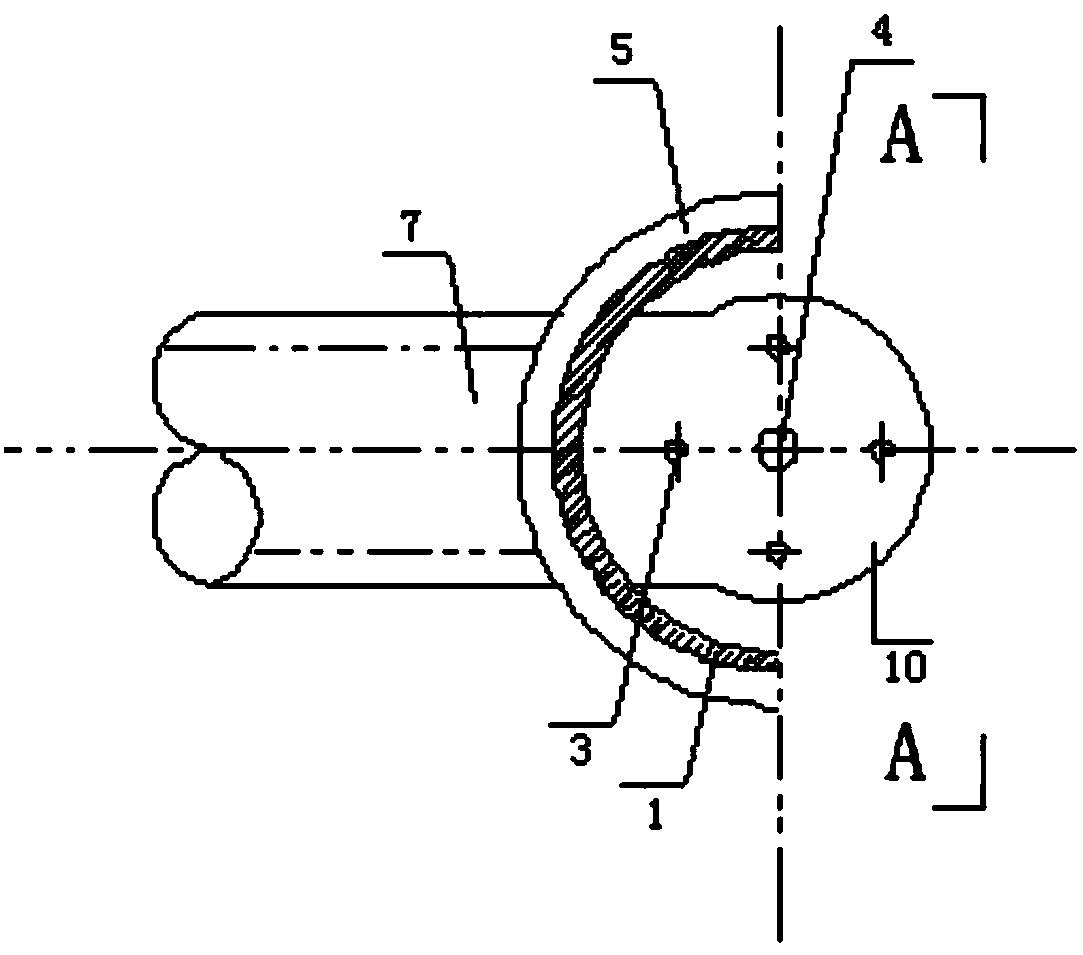

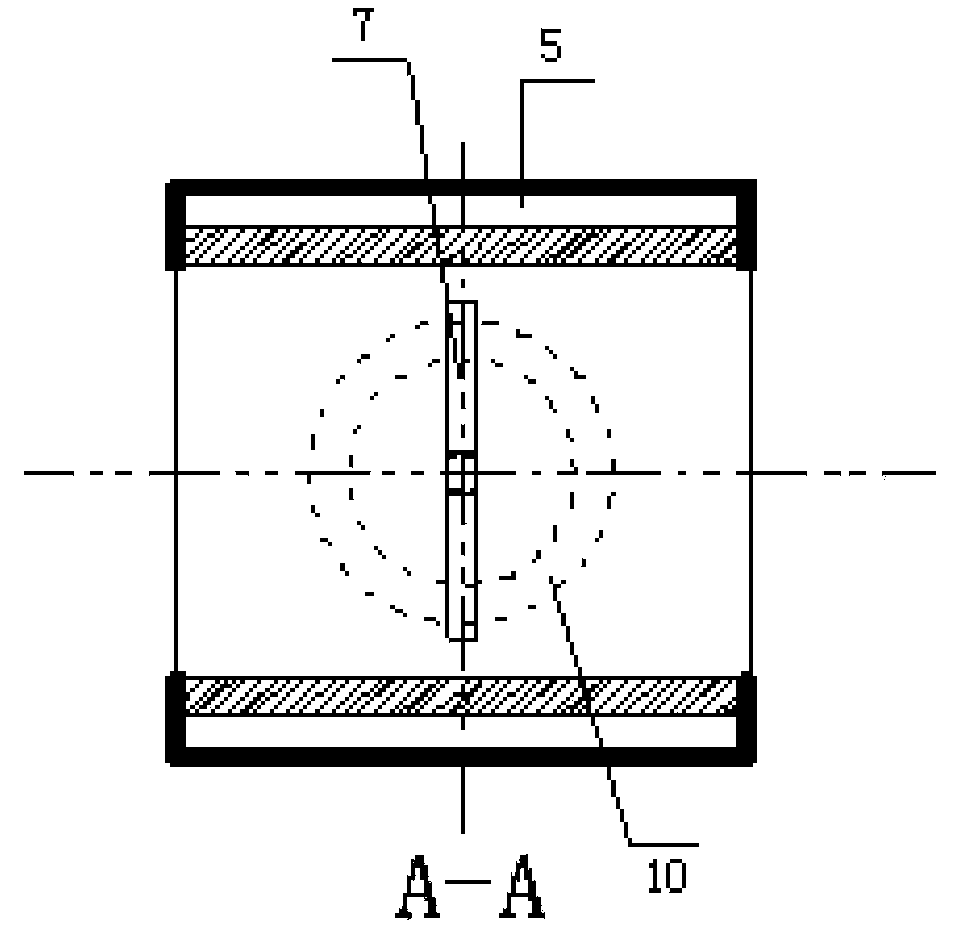

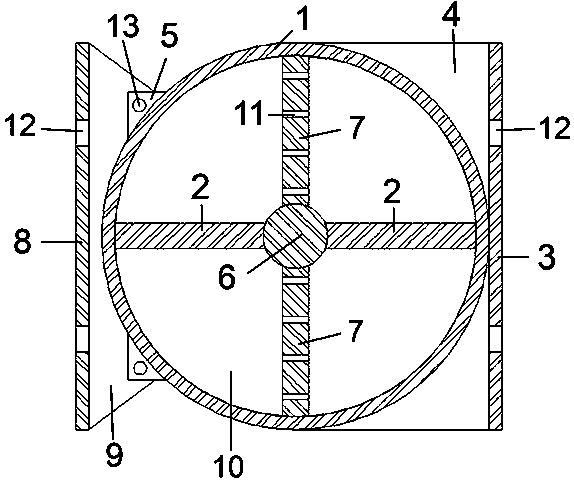

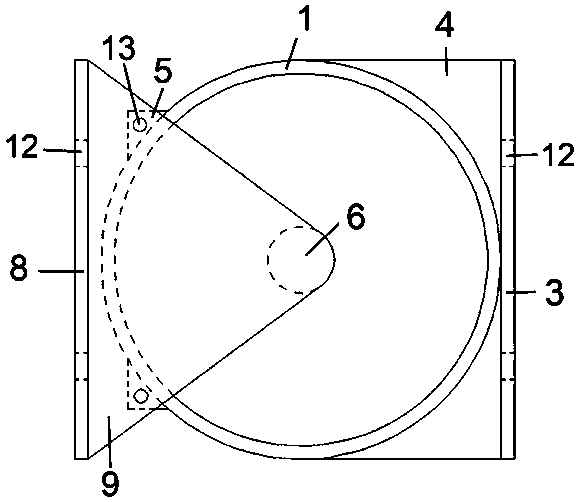

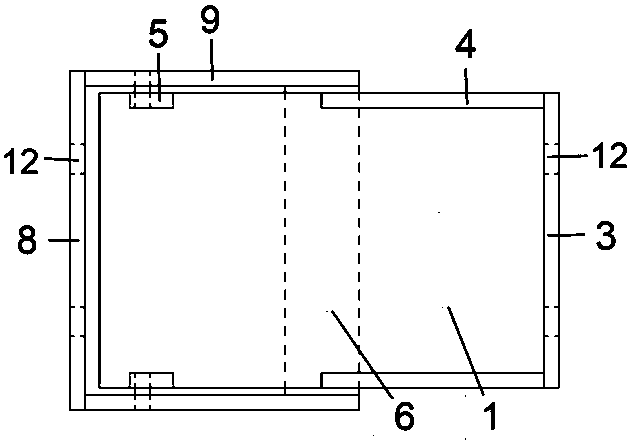

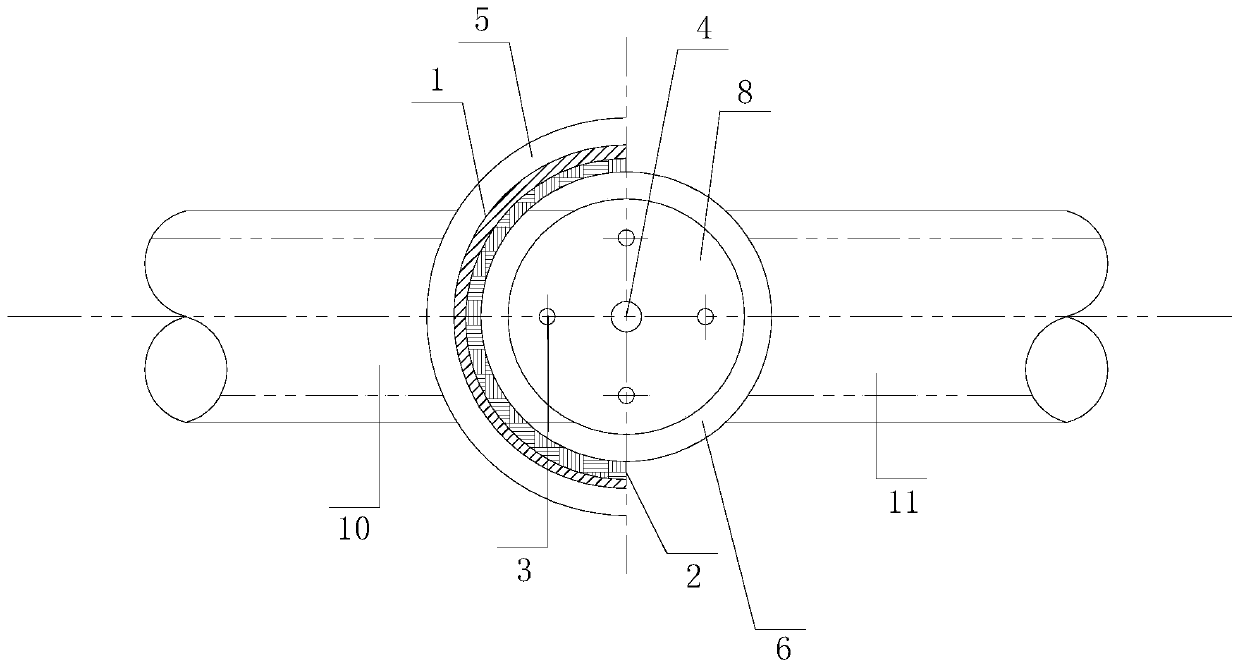

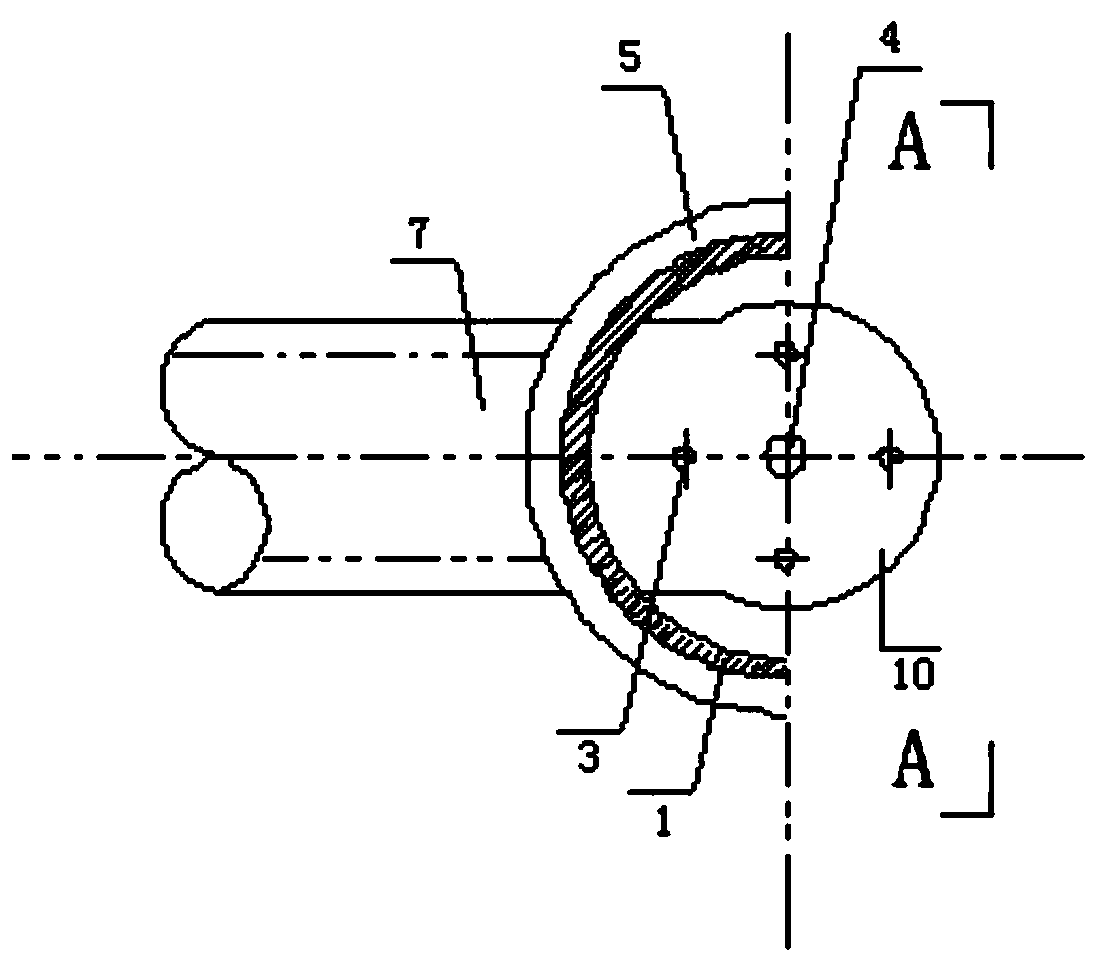

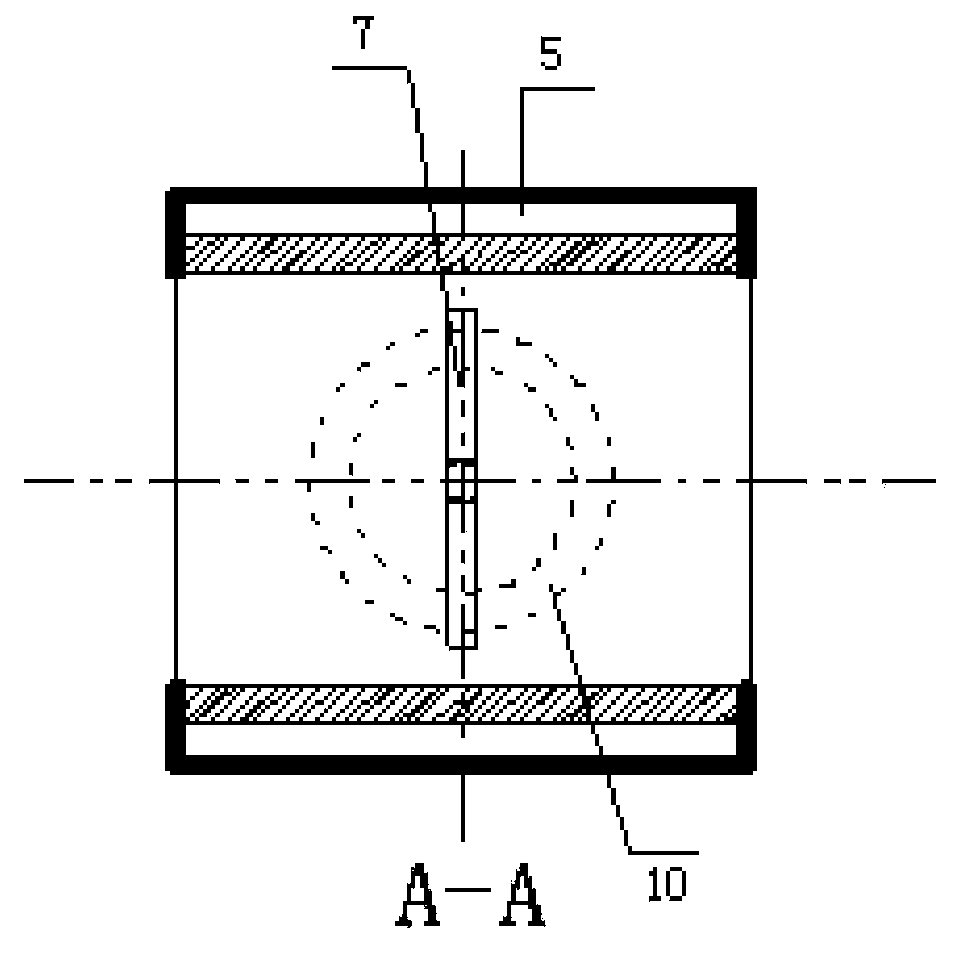

Friction plastic hinge structure capable of controlling energy dissipation

ActiveCN108442516AAccurate energy consumptionReduce the impactProtective buildings/sheltersShock proofingEnergy consumptionPlastic property

The invention relates to a friction plastic hinge structure capable of controlling energy consumption. The friction plastic hinge structure capable of controlling the energy consumption comprises a rotating unit and a basic support unit. The rotating unit is composed of a profiled bar beam (1-2), a rotating pin (2), a circular-arc-shaped loading plate (3), a tightening ring loading screw (4), tightening ring nuts (5) and a rotating single connecting plate (12), wherein the profiled bar beam (1-2) is connected with the rotating single connecting p0late (12), upper and lower plates of the circular-arc-shaped loading plate (3) are connected with the rotating single connecting plate (12) through the rotating pin (2), and the tightening ring loading screw (4) is connected with the circular-arc-shaped loading plate (3) in a bolted mode through the tightening ring nuts (5). The basic support unit is composed of a profiled bar beam (1-1), friction materials (6), a double connecting plate (8) and a circular-pipe-shaped sealing plate (9), wherein the profiled bar beam (1-1) is connected with the circular-pipe-shaped sealing plate (9), the double connecting plate (8) is connected with the inner wall of the circular-pipe-shaped sealing plate (9), and the friction materials (6) are attached to the outer wall of the circular-pipe-shaped sealing plate (9).

Owner:兰州瑟百瑞减震技术开发有限公司

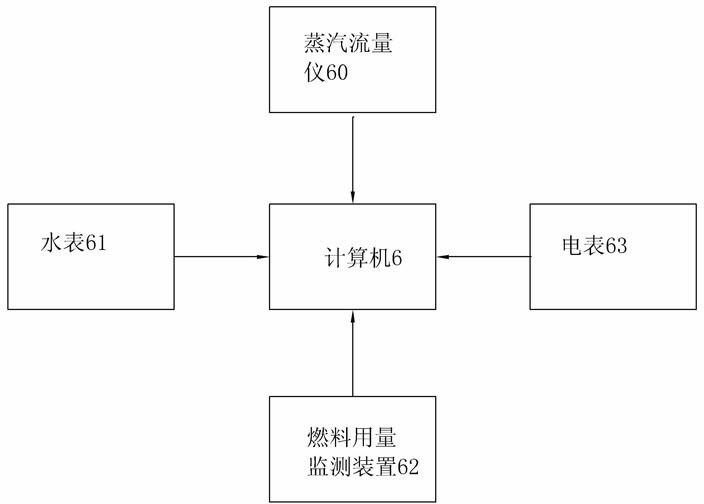

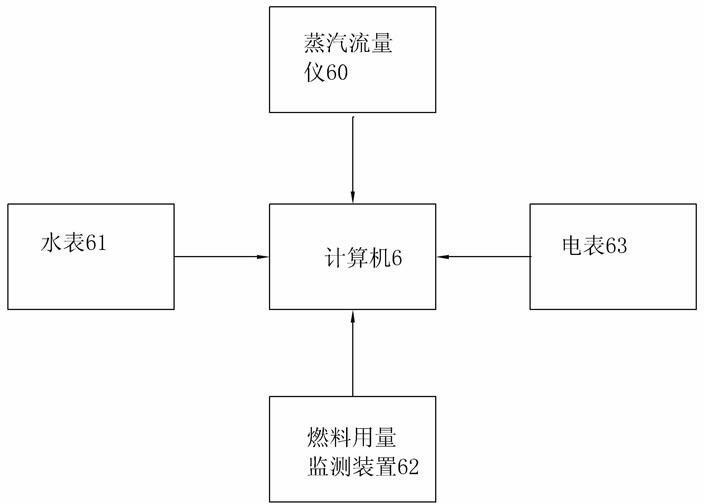

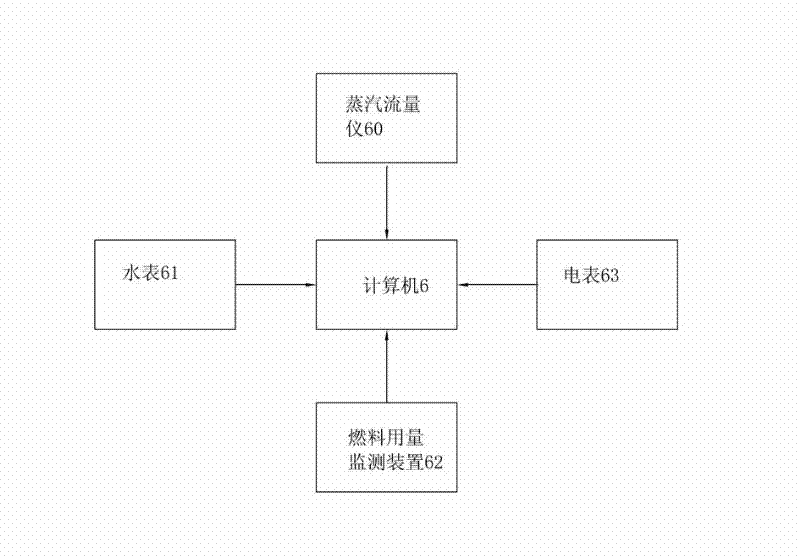

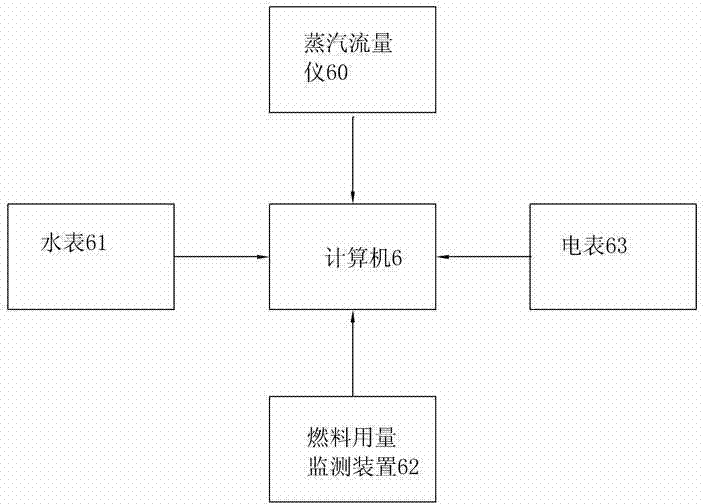

System and method for monitoring energy consumption cost of spiral feeding type small-sized steam boiler on line

ActiveCN102141243AClear dataImprove average operating efficiencyBoiler indication operationsBoiler controlElectricity meterProcess engineering

The invention discloses a system and a method for monitoring energy consumption cost of a spiral feeding type small-sized steam boiler on line, which can acquire energy consumption and cost data of the boiler in time, accurately calculate single-circle energy consumption cost and unit steam energy consumption cost and provide a basis for the improvement on the average operating efficiency of the boiler so as to achieve an energy-saving effect. In the system, a steam flow instrument, a fuel using amount monitoring device, an electricity meter and a water power flow instrument are in communication connection with a computer, so that the energy consumption cost of the boiler can be conveniently measured; the energy consumption cost is reduced to the lowest limit by reasonably adjusting the operating condition and the fuel of the boiler through the energy consumption and cost data which is monitored in real time by the system; simultaneously, all parameters are monitored on line, data acquisition and calculation processes are finished by the computer, and the authenticity of the data is reflected; and the on-line monitoring method provides in-time and accurate energy consumption data and technical indexes for the operation of the boiler.

Owner:湖南兆丰新能源技术有限公司

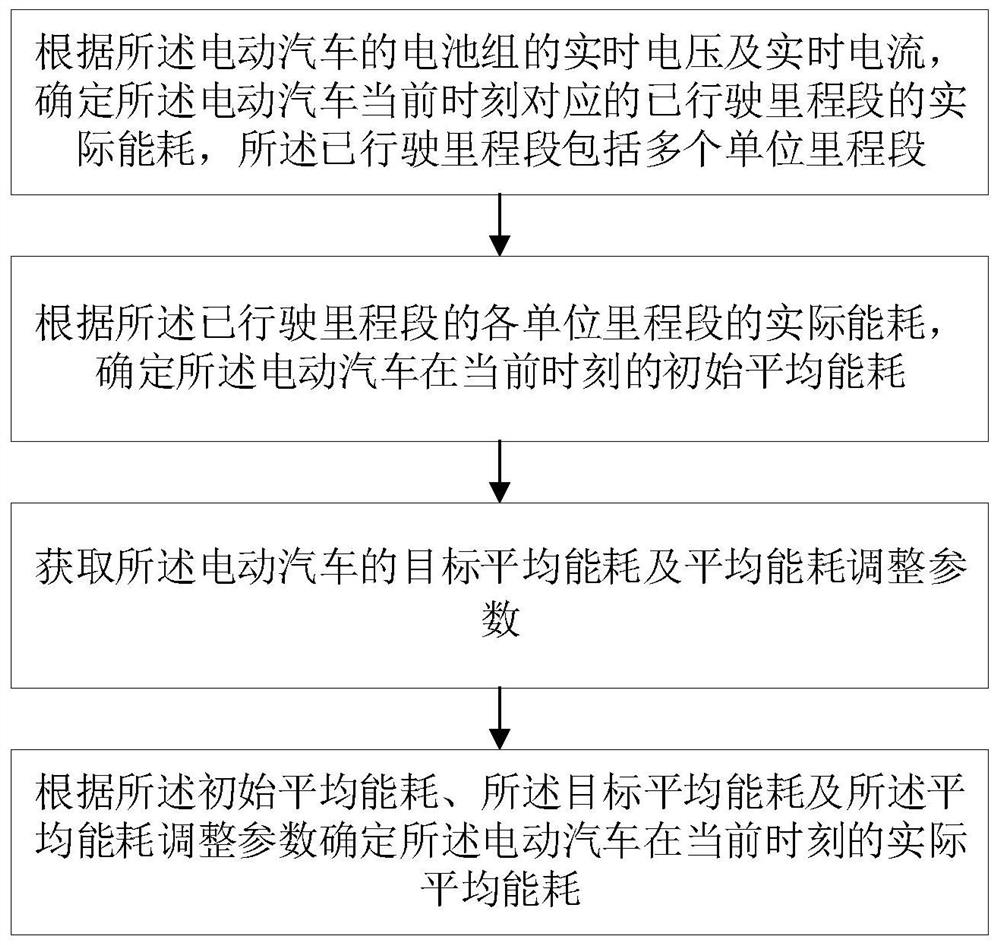

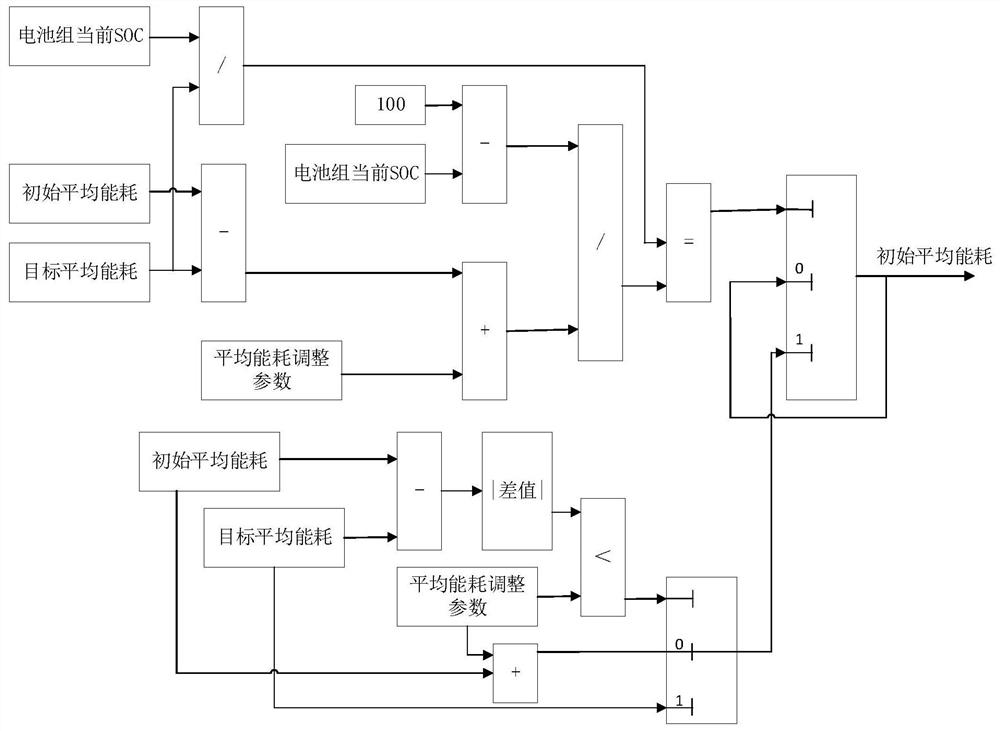

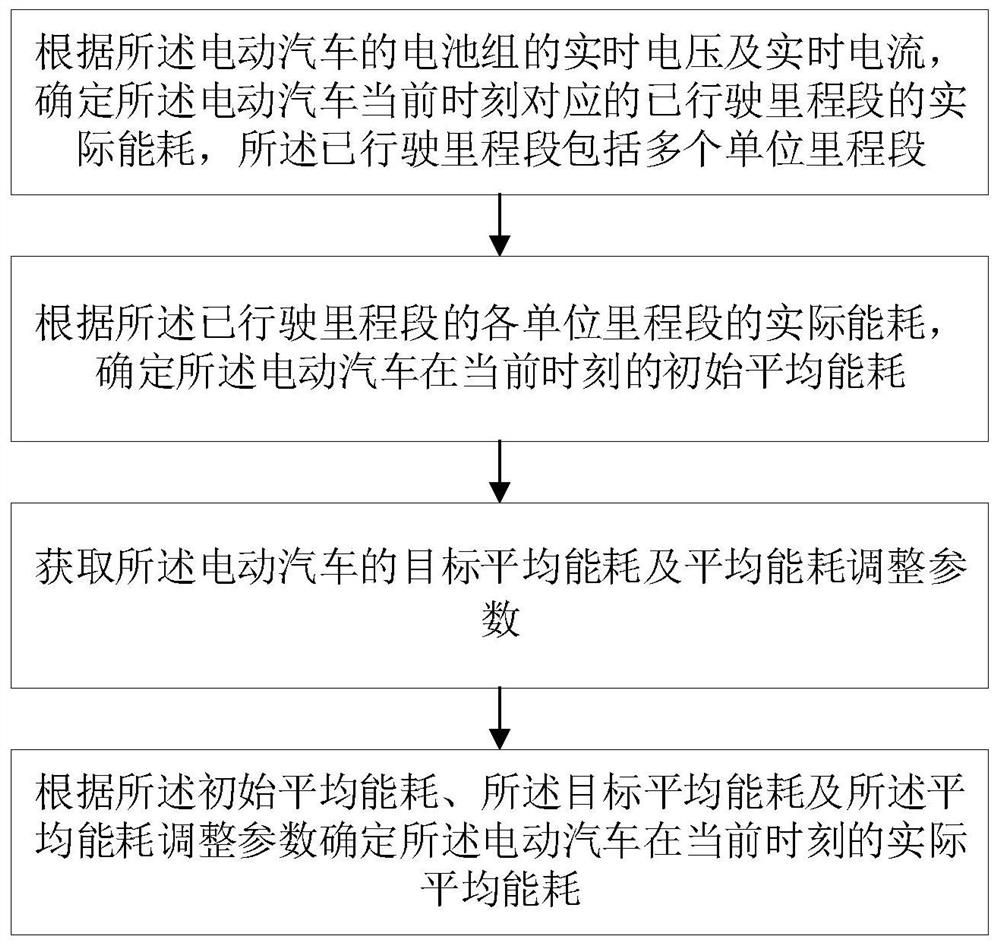

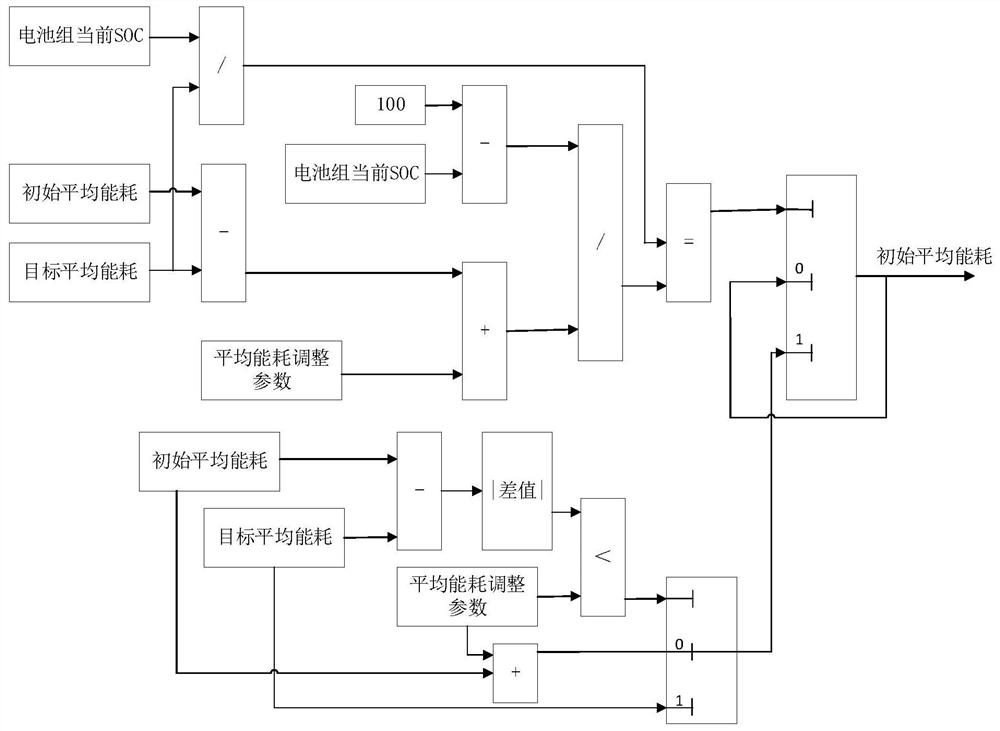

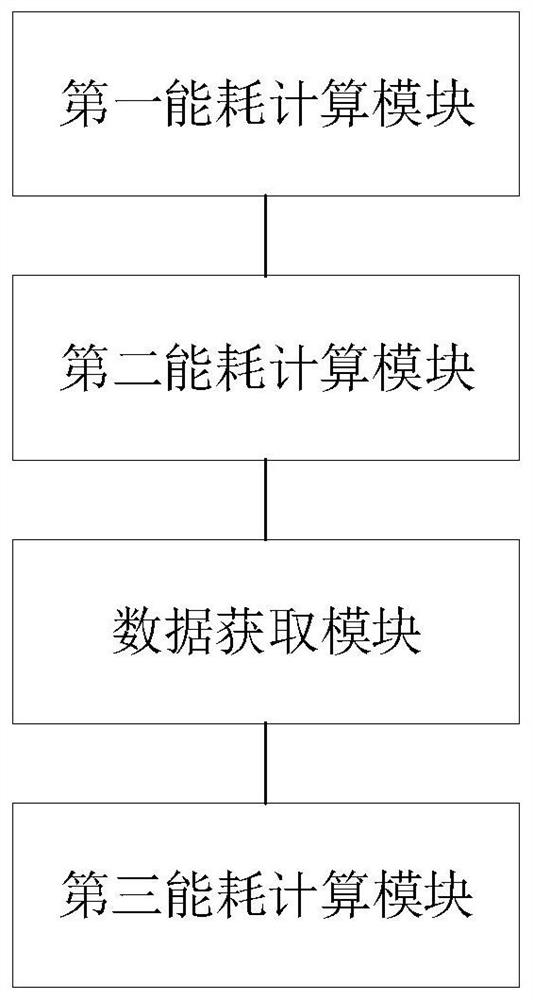

Electric vehicle average energy consumption prediction method and device

ActiveCN112810614AAccurate Energy ConsumptionAccurate calculation of actual energy consumptionElectric devicesOperating modesVehicle miles of travelElectric vehicle

The embodiment of the invention provides an electric vehicle average energy consumption prediction method and an electric vehicle average energy consumption prediction device, which relate to the technical field of electric vehicles. The method comprises the steps that according to the real-time voltage and the real-time current of a battery pack of the electric vehicle, the actual energy consumption of a traveled mileage segment corresponding to the current moment of the electric vehicle is determined, and the traveled mileage segment comprises a plurality of unit mileage segments; according to the actual energy consumption of each unit mileage section of the traveled mileage section, the initial average energy consumption of the electric vehicle at the current moment is determined; target average energy consumption and average energy consumption adjustment parameters of the electric vehicle are obtained; and according to the initial average energy consumption, the target average energy consumption and the average energy consumption adjustment parameters, the actual average energy consumption of the electric vehicle at the current moment is determined. Thus, the actual average energy consumption of the electric vehicle at the current moment can be accurately calculated in real time.

Owner:GREAT WALL MOTOR CO LTD

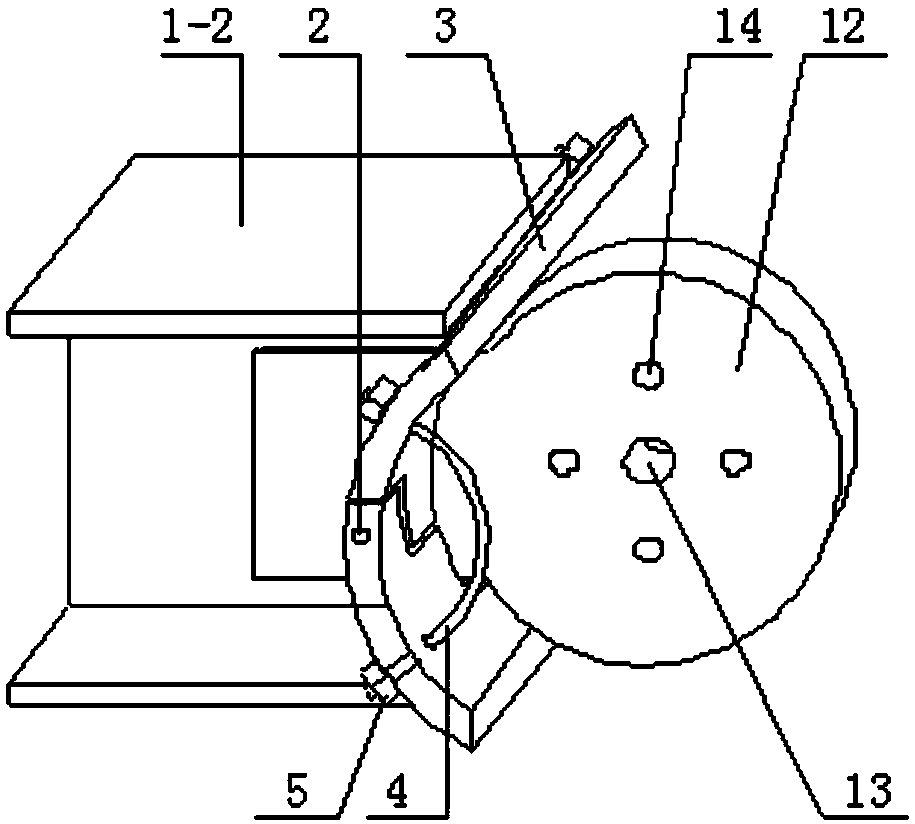

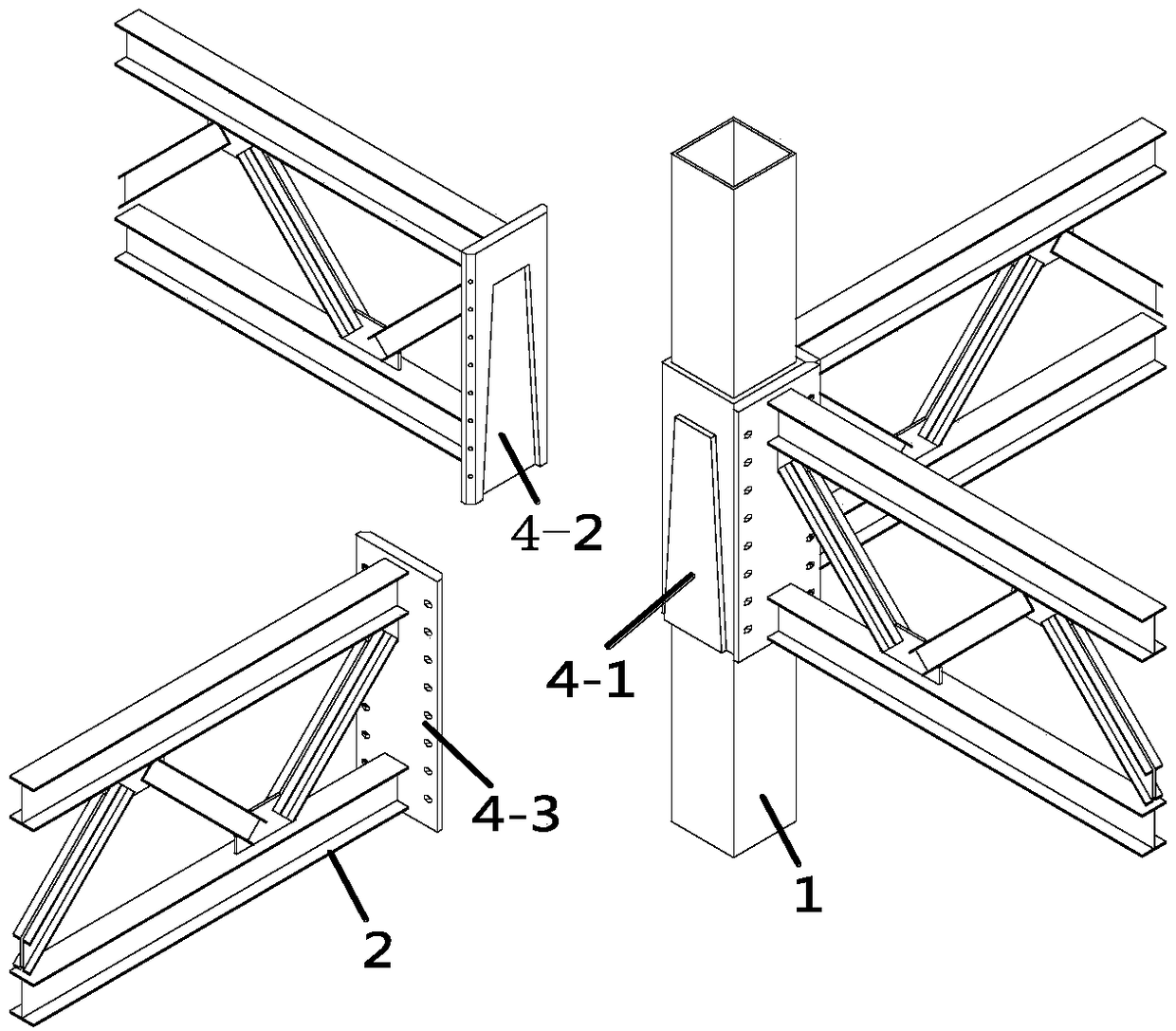

Friction plastic hinge suitable for truss structure and frame structure and design method

ActiveCN107724530AAccurate energy consumptionSimple structureBuilding constructionsEngineeringPlastic hinge

The invention relates to a friction plastic hinge suitable for a truss structure and a frame structure and a design method. The left side of an arc-shaped sealing plate is connected with a left chordmember, a lining plate is stuck on the right side of the arc-shaped sealing plate, a left connection plate is arranged in the middle of the lining plate, and a limit hole and a rotation hole are formed in the left connection plate; a circular-tube-shaped sealing plate is arranged on a right unit, the right side of the circular-tube-shaped sealing plate is connected with a right chord member, and afriction material is stuck on the left side of the circular-tube-shaped sealing plate; two right connection plates are arranged in the middle of the circular-tube-shaped sealing plate, and limit holes and rotation holes are formed in the right connection plates. The design method comprises the steps that 1, under the situation that a beam is normally used, the continuity is kept, and the outer surface of the friction material is tangent to a flange of the beam; 2, under the effect of the major earthquake, limit pin are preferentially cut off, the area sum of the limit pins is set to be smaller than that of rotation pins, and design parameters are determined by formulas.

Owner:兰州瑟百瑞减震技术开发有限公司

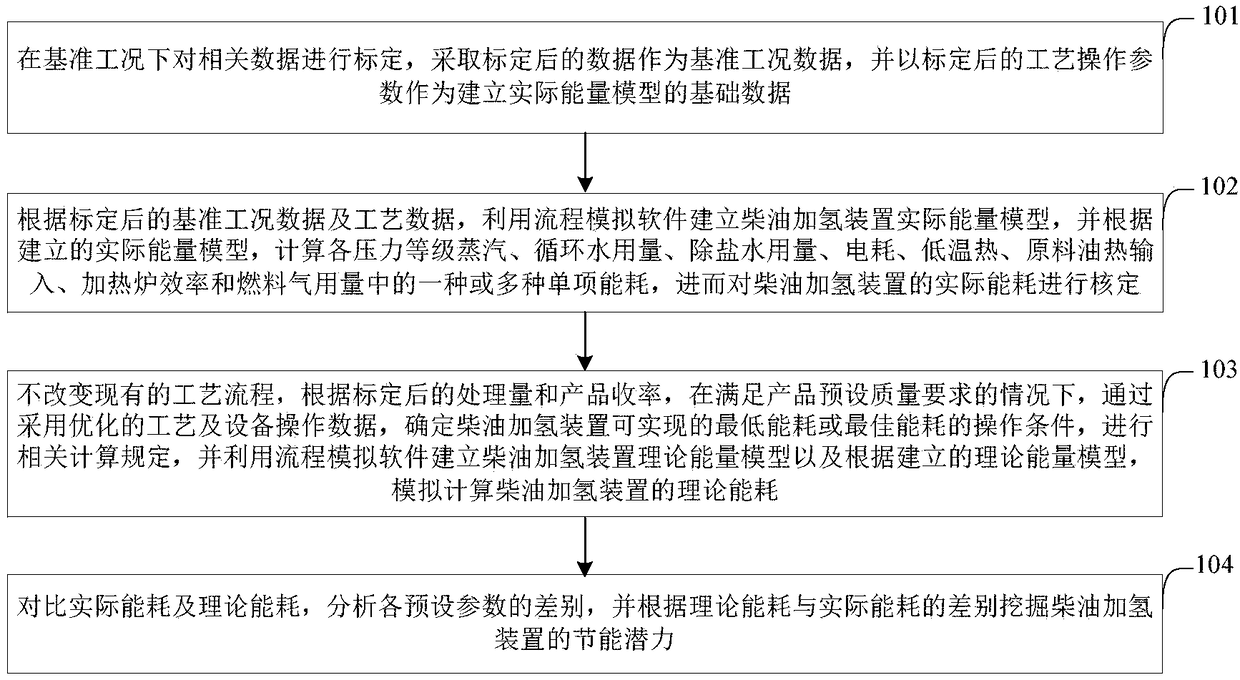

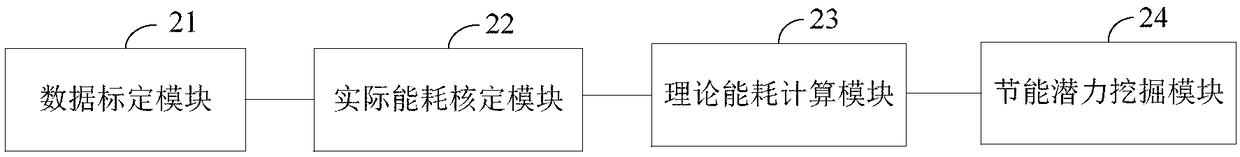

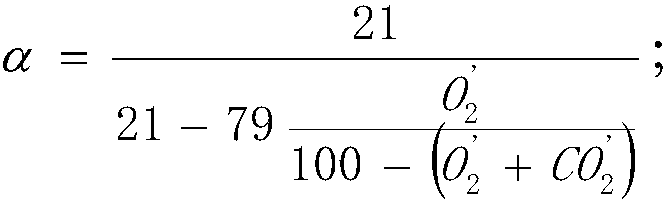

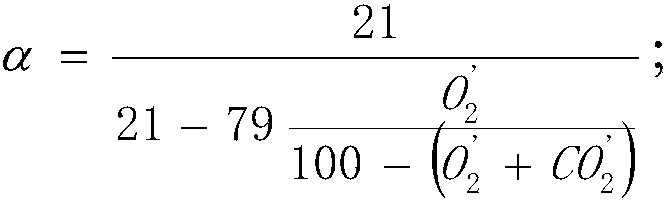

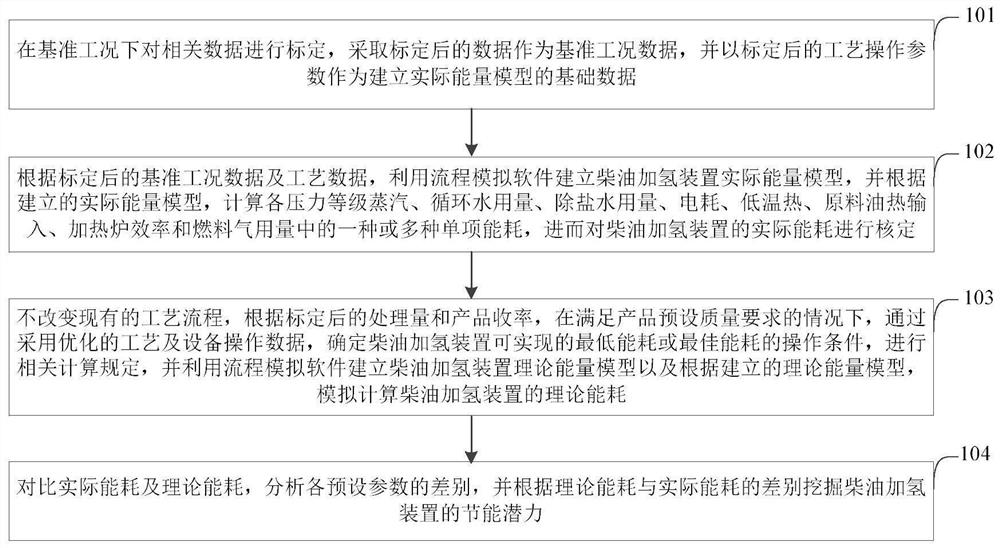

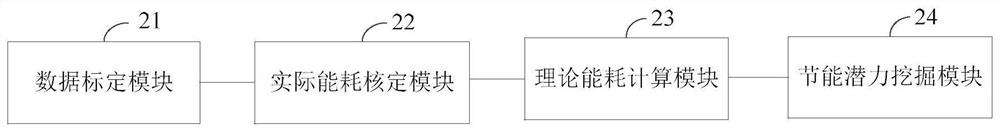

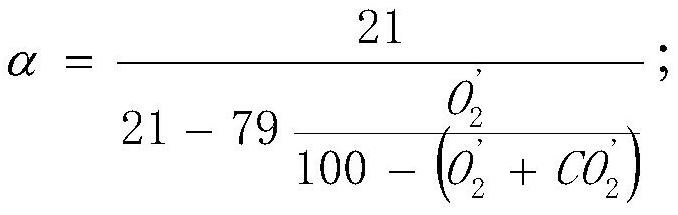

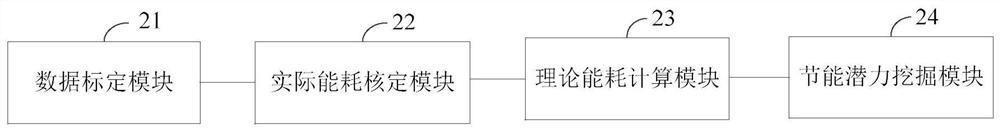

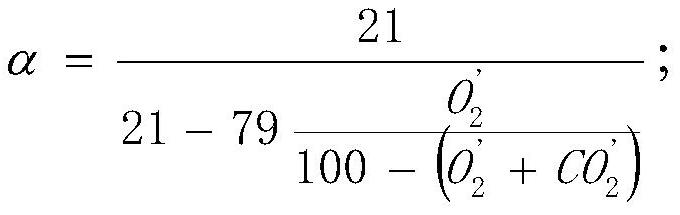

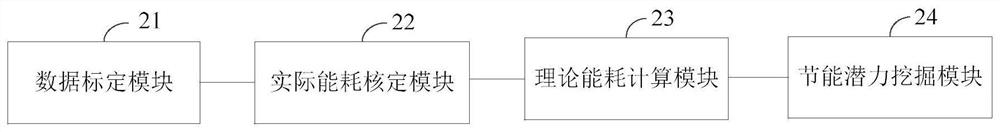

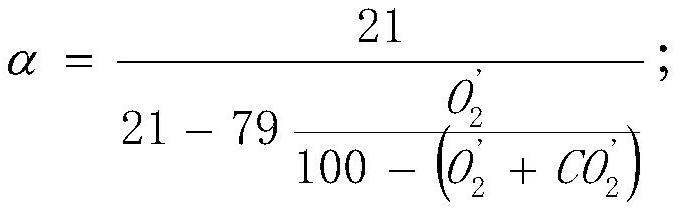

A diesel oil hydrogenation energy consumption analysis method and device

ActiveCN109299836AConducive to tapping energy-saving potentialAccurate Energy ConsumptionTechnology managementResourcesAnalysis methodOperant conditioning

The present invention provides a diesel oil hydrogenation energy consumption analysis method and device. The method comprises: according to calibrated reference working condition data and process data, establishing actual energy model of diesel oil hydrogenation unit and verifying the actual energy consumption of the diesel oil hydrogenation unit; without changing the existing process flow, according to the calibrated throughput and product yield, under the condition of satisfying the preset quality requirement of the product, by adopting the optimized process and equipment operation data, thelowest energy consumption of the diesel hydrogenation unit can be determined, and the relevant calculation regulations are carried out, and the theoretical energy model of the diesel hydrogenation unit is established and the theoretical energy consumption of the diesel hydrogenation unit is simulated and calculated. By comparing the actual energy consumption with the theoretical energy consumption, the energy-saving potential of the diesel hydrogenation unit is explored. At first, that invention can obtain the low energy consumption that the diesel oil hydrogenation device can theoretically achieve, and then compares the low energy consumption that the diesel oil hydrogenation device can theoretically achieve with the actual energy consumption, thereby facilitating to tap the energy-saving potential of the diesel oil hydrogenation device.

Owner:CHINA PETROLEUM & CHEM CORP +1

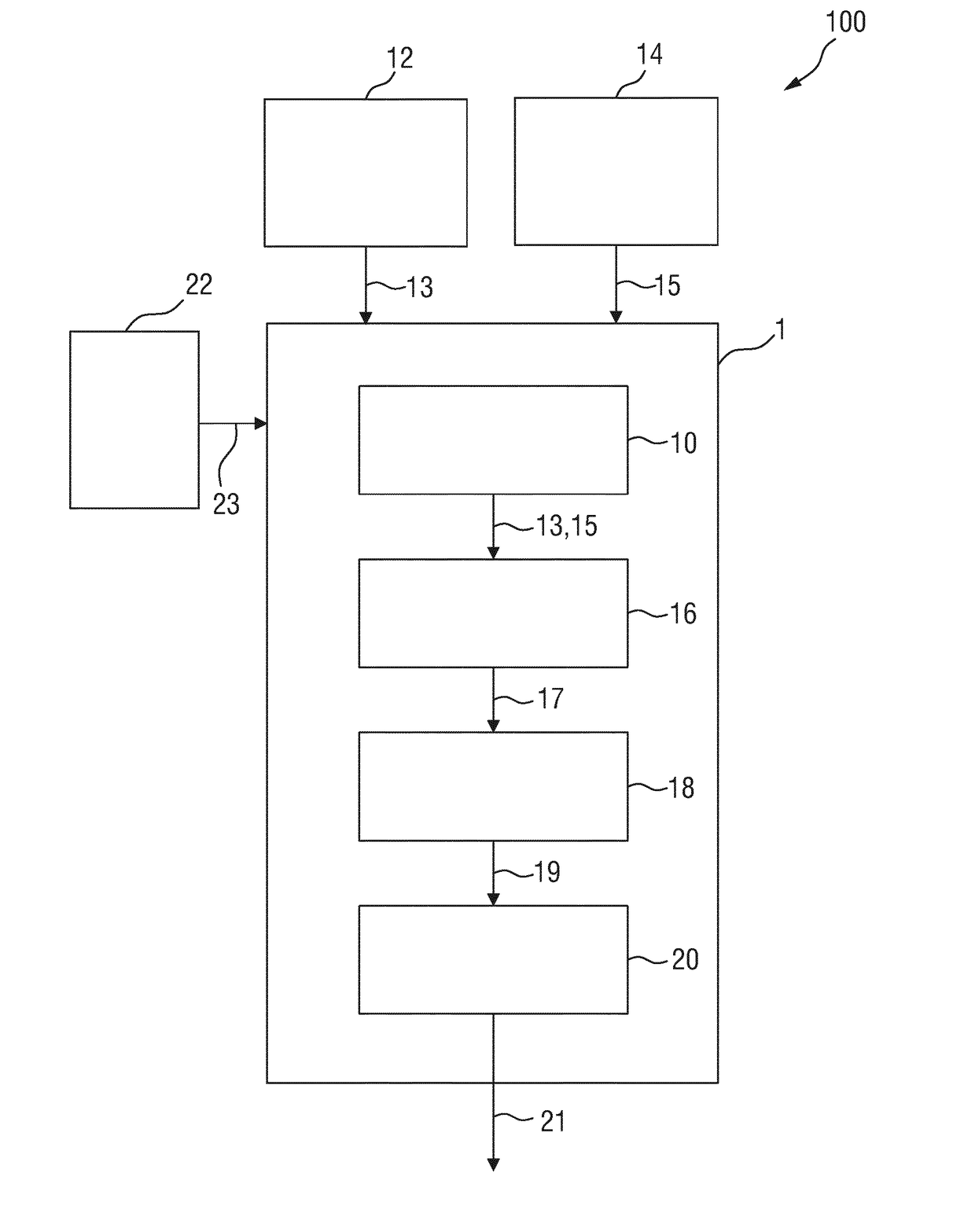

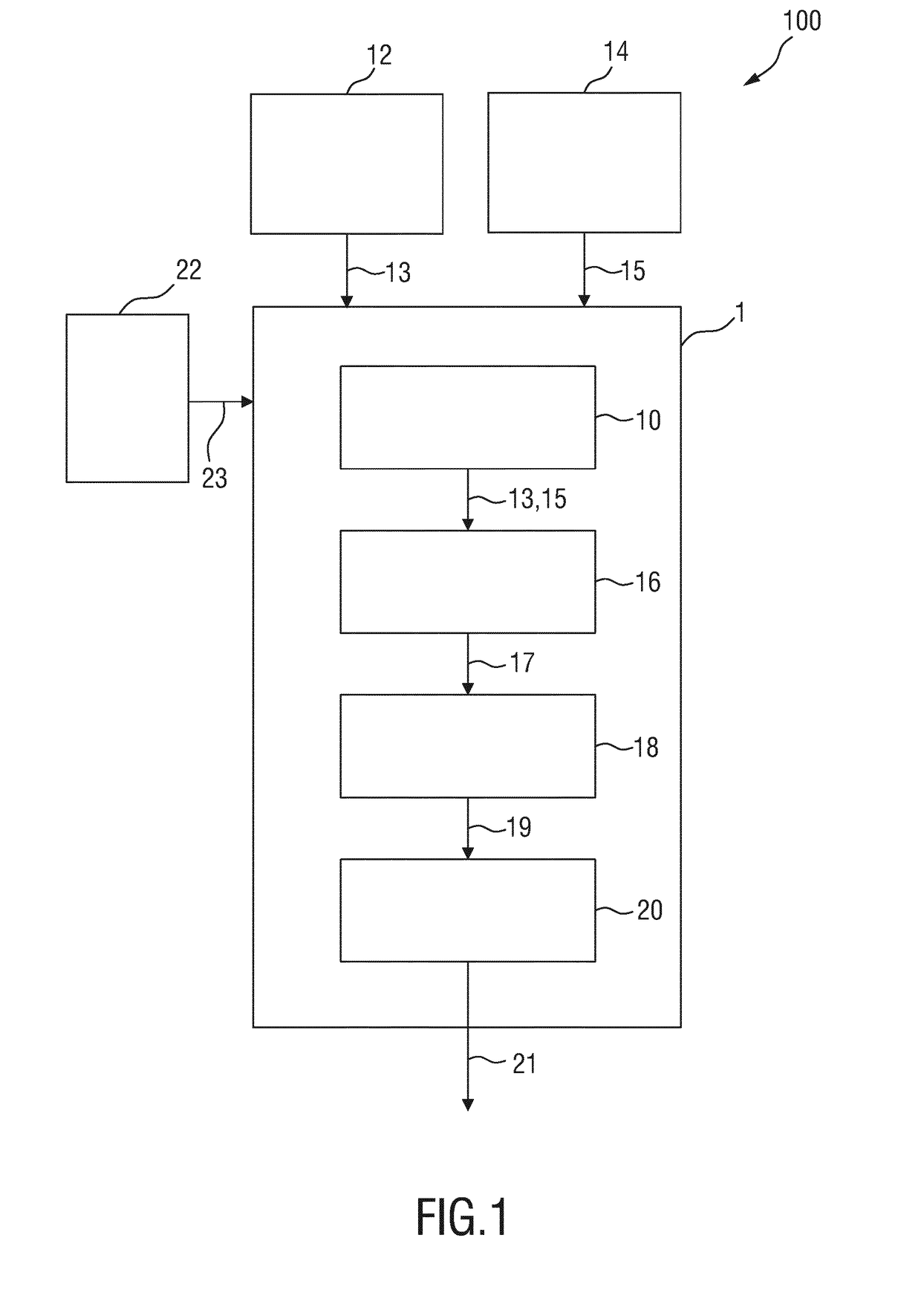

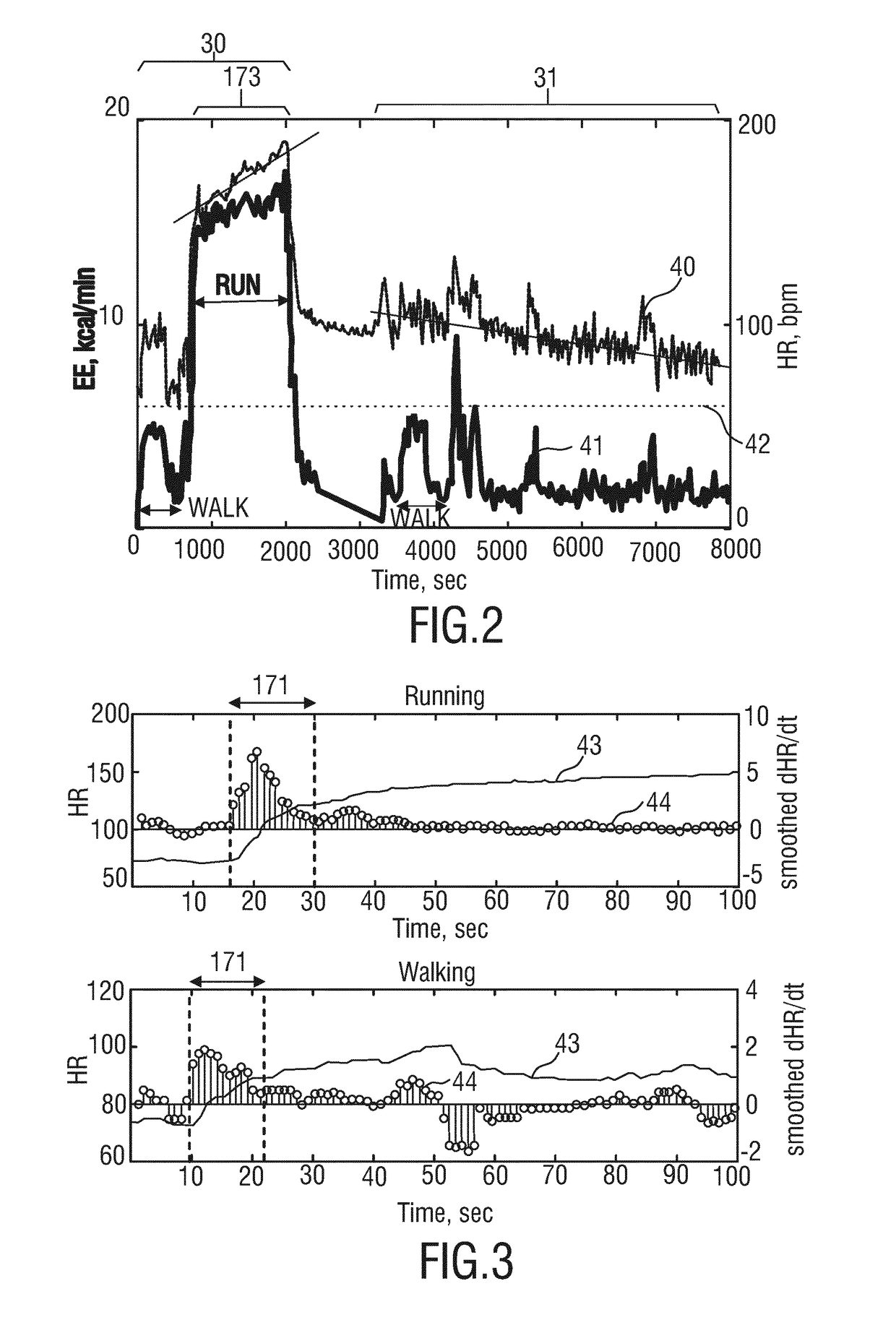

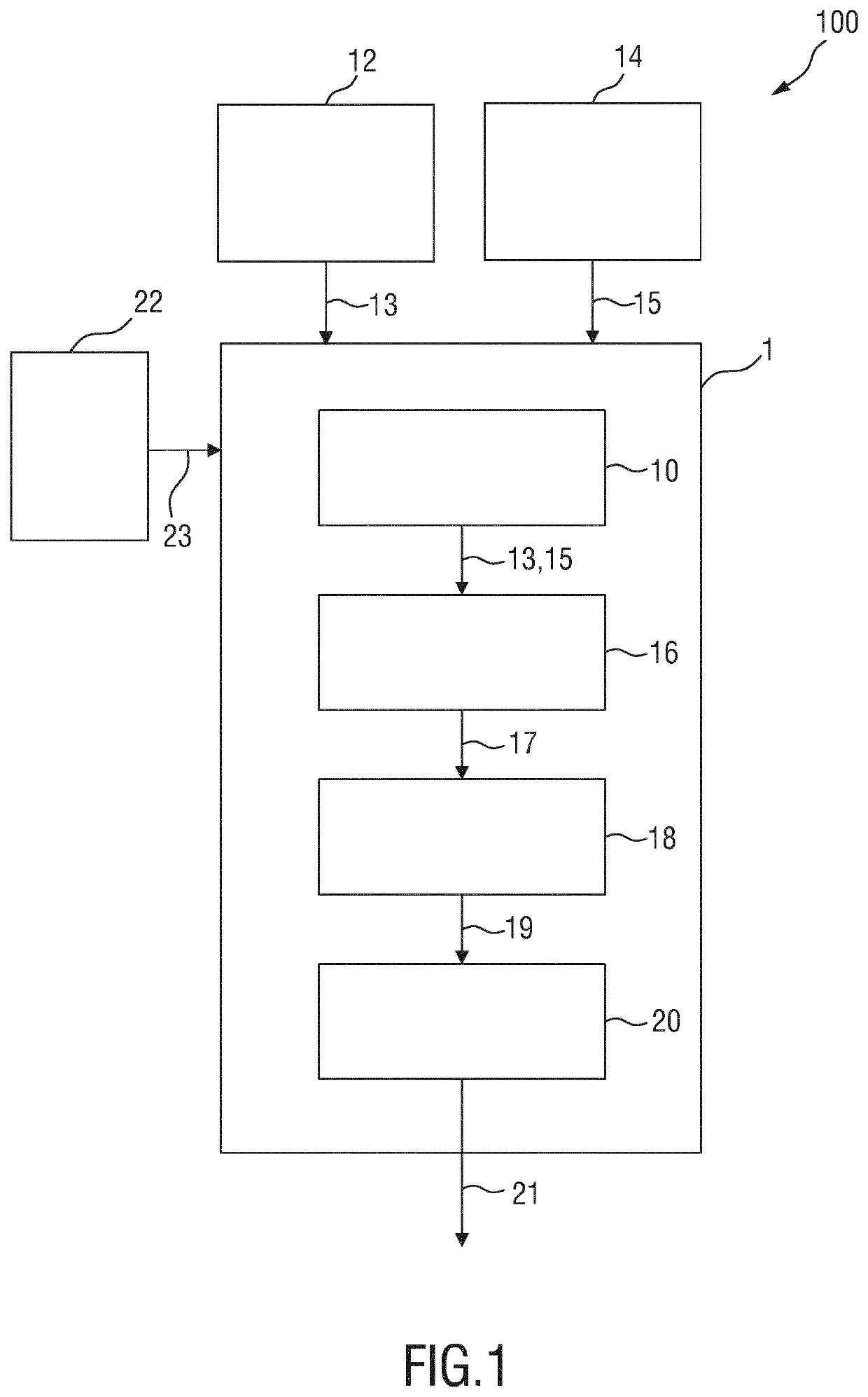

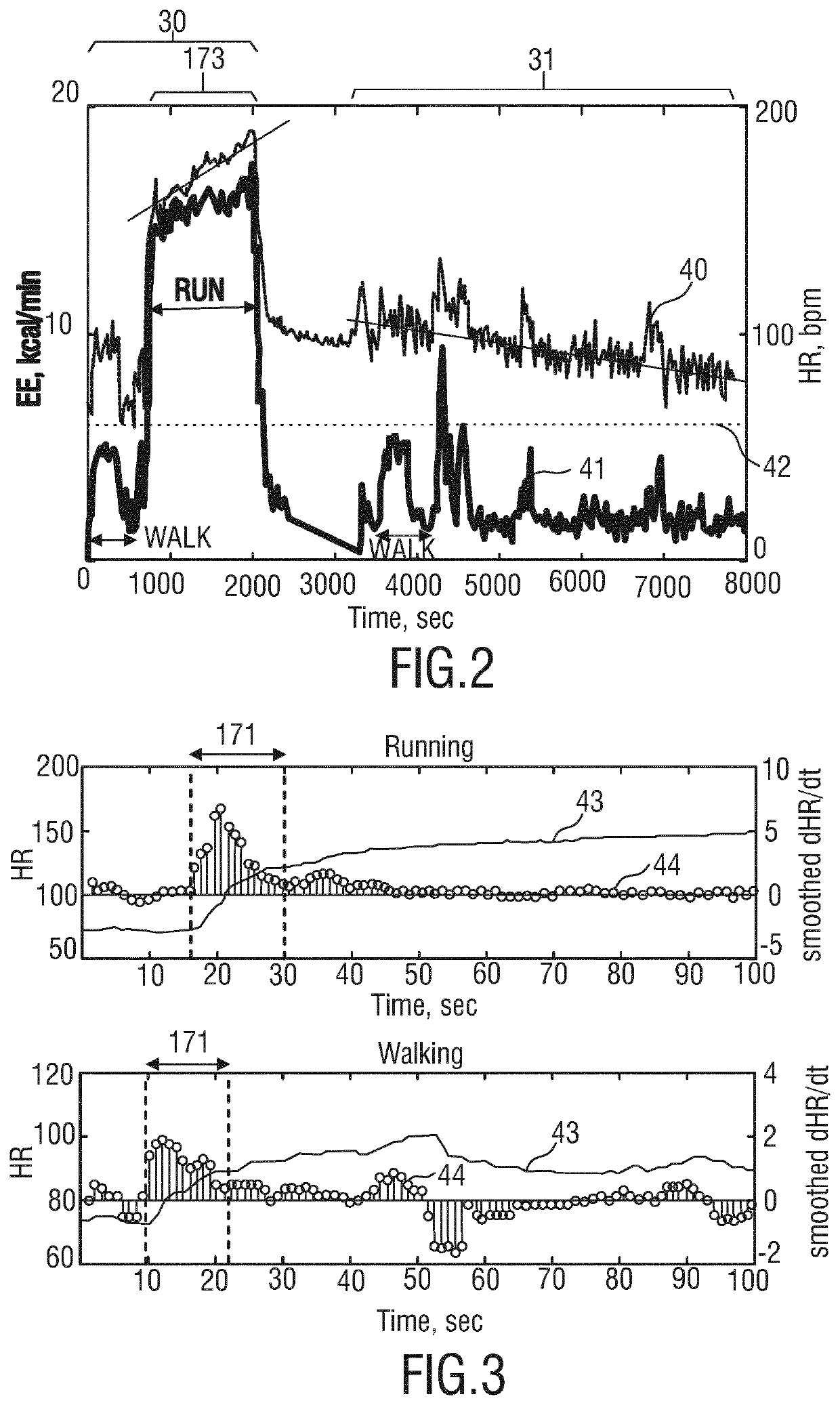

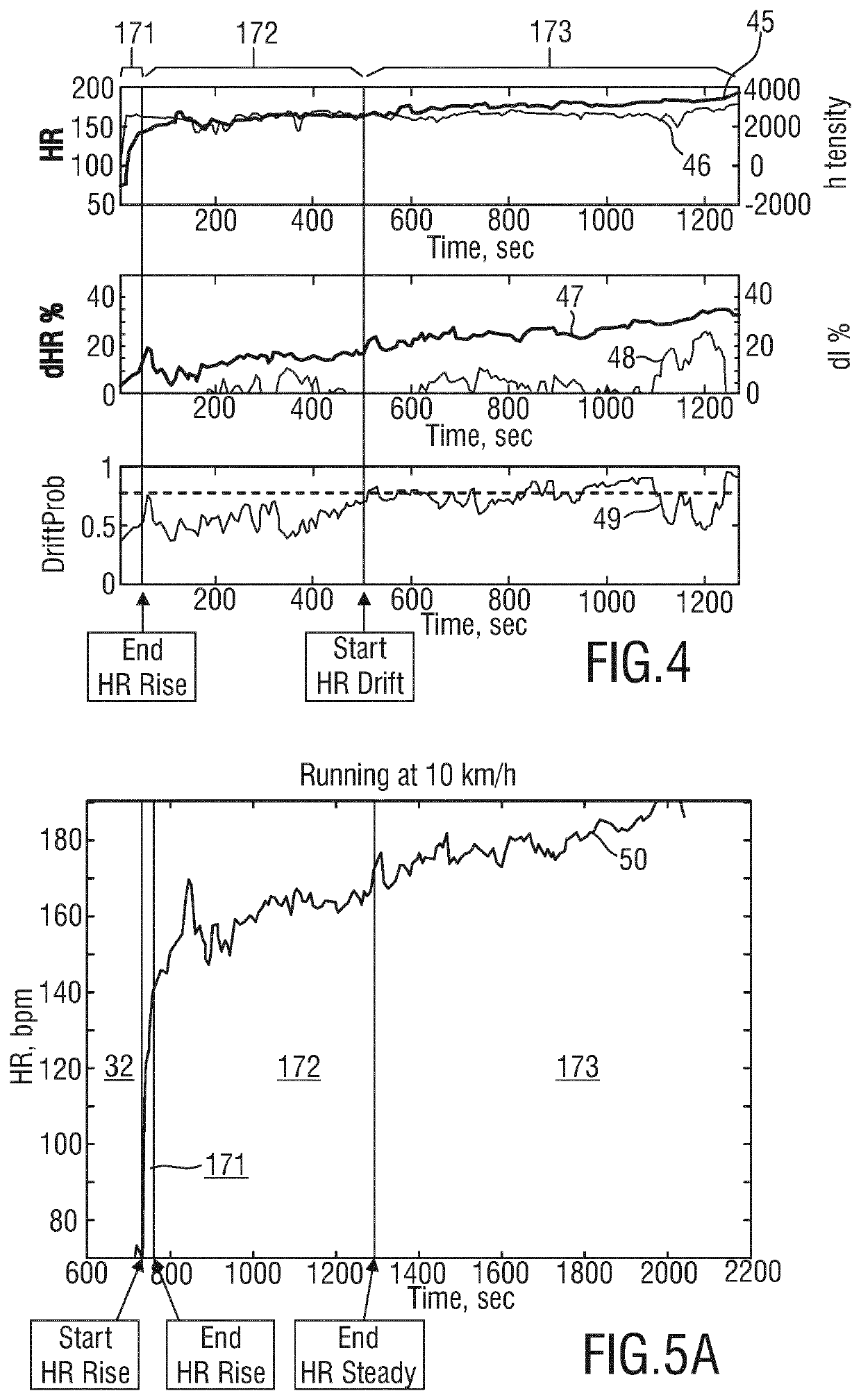

Device, system and method for estimating the energy expenditure of a person

ActiveUS20180249951A1Less complexReduced additional effortSensorsMeasuring/recording heart/pulse ratePulse rateEnergy expenditure

The present invention relates to a device for accurately estimating the energy expenditure of a person, in particular by which the effect of cardiovascular drift is taken into account. The device comprises an input unit (10) for obtaining a movement signal (13) representing physical activity of the person and a heart rate signal (15) representing the heart rate of the person, a cardiovascular drift determination unit (16) for determining cardiovascular drift phases (17) from said movement signal (13) and either said heart rate signal (15) and / or one or more cardiovascular drift related signals (23) carrying information on one or more of amount of sweat, weight loss, temperature rise, blood lactate concentration and physical fatigue of the person, a correction unit (18) for correcting the heart rate signal (15) generated and representing the heart rate during a cardiovascular drift phase, and an estimation unit (20) for estimating the energy expenditure of the person from the corrected heart rate signal (19).

Owner:KONINKLJIJKE PHILIPS NV

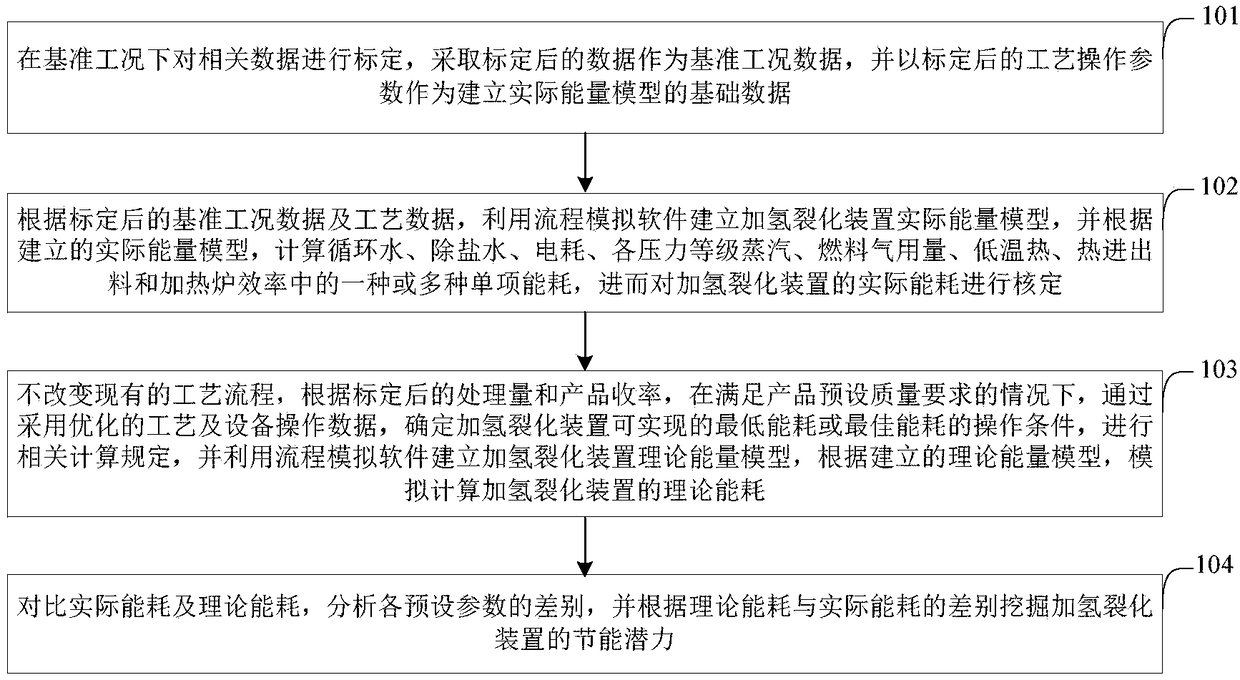

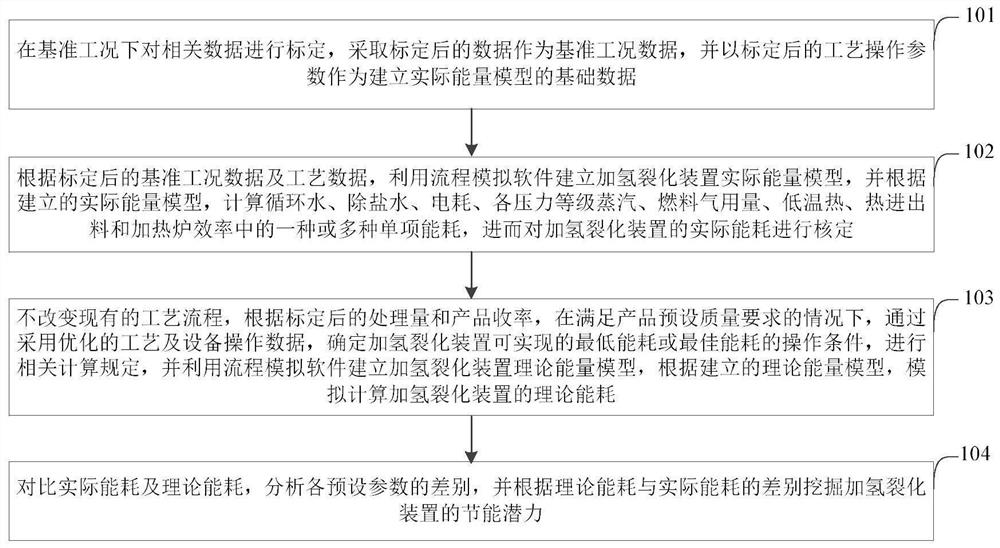

An energy analysis method and device for hydrocracking

ActiveCN109299482AReduce energy consumptionHigh energy consumptionTechnology managementHydrocarbon oil crackingProcess engineeringAnalysis method

The invention provides an energy analysis method and device for hydrocracking. The method comprises the following steps: establishing an actual energy model of a hydrocracking unit and verifying the actual energy consumption of the hydrocracking unit according to the calibrated reference working condition data and the process data; without changing the existing process flow. According to the calibrated throughput and product yield, Under the condition of satisfying the preset quality requirements of the product, by using the optimized process and equipment operation data, the operation conditions of the lowest energy consumption of the hydrocracking unit can be determined, the relevant calculation regulations are carried out, the theoretical energy model of the hydrocracking unit is established, and the theoretical energy consumption of the hydrocracking unit is simulated and calculated. By comparing the actual energy consumption with the theoretical energy consumption, the energy-saving potential of the hydrocracking unit is explored. At first, that invention can obtain the low energy consumption that the hydrocracking unit can achieve in theory, and then compare the low energy consumption that the hydrocracking unit can achieve in theory with the actual energy consumption, thereby facilitating to tap the energy-saving potential of the hydrocracking unit.

Owner:CHINA PETROLEUM & CHEM CORP +1

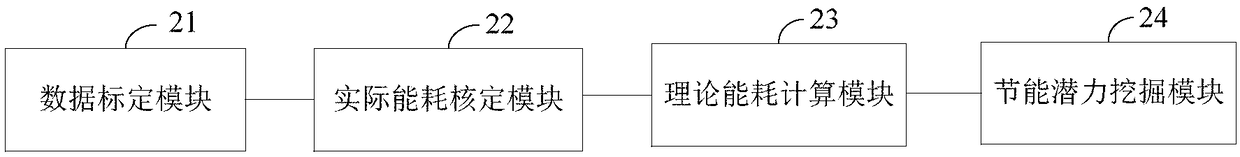

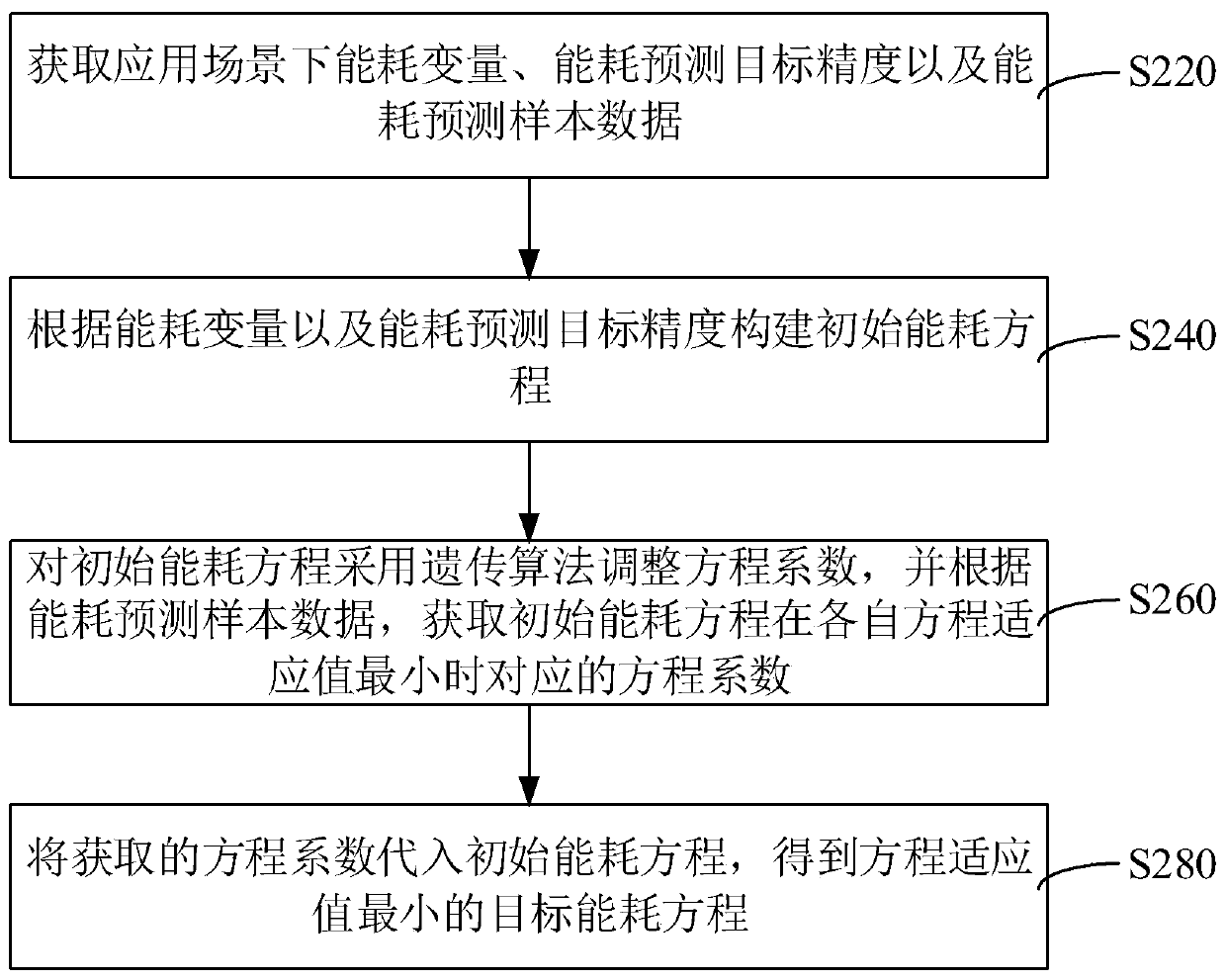

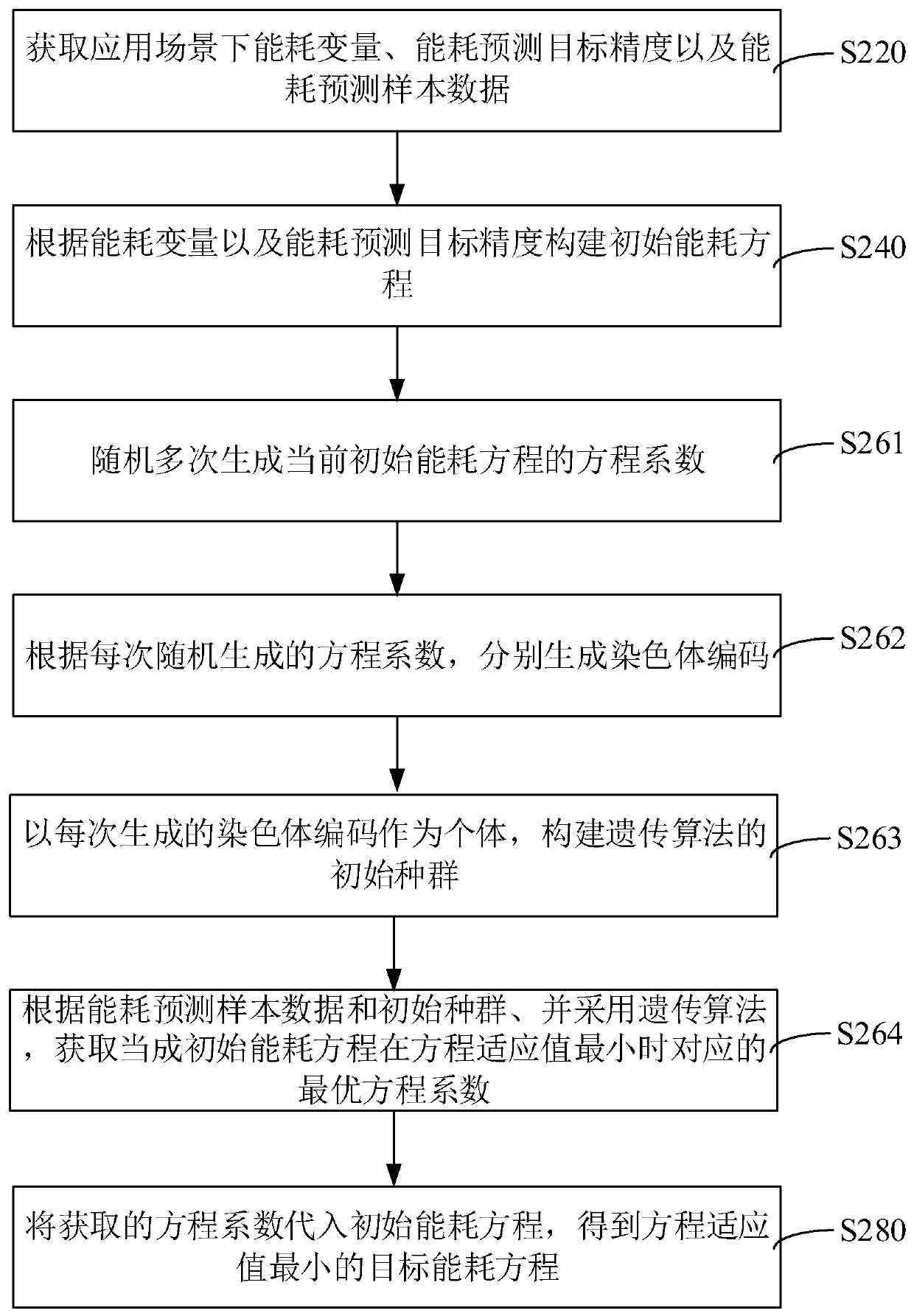

Energy consumption equation construction method and device and energy consumption prediction method and device

PendingCN111126707ASimple and accurate prediction of energy consumptionAccurate Energy ConsumptionForecastingGenetic algorithmsPhysicsGenetics algorithms

The invention relates to an energy consumption equation construction method and apparatus, a computer device and a storage medium. The method comprises the steps of obtaining an energy consumption variable, the energy consumption prediction target precision and energy consumption prediction sample data in an application scene; constructing an initial energy consumption equation according to the energy consumption variable and the energy consumption prediction target precision; adjusting equation coefficients of the initial energy consumption equations by adopting a genetic algorithm, and obtaining equation coefficients corresponding to the initial energy consumption equations when respective equation adaptive values are minimum according to the energy consumption prediction sample data; and substituting the obtained equation coefficient into the initial energy consumption equation to obtain a target energy consumption equation with the minimum equation adaptive value. In the whole process, the target energy consumption equation is accurately constructed by adopting the genetic algorithm based on the variable corresponding to the current application scene, and the energy consumptioncan be simply and accurately predicted directly through the accurately constructed target energy consumption equation in the subsequent energy consumption prediction process. In addition, the invention further provides an energy consumption prediction method and device, computer equipment and a storage medium.

Owner:HNAC TECH

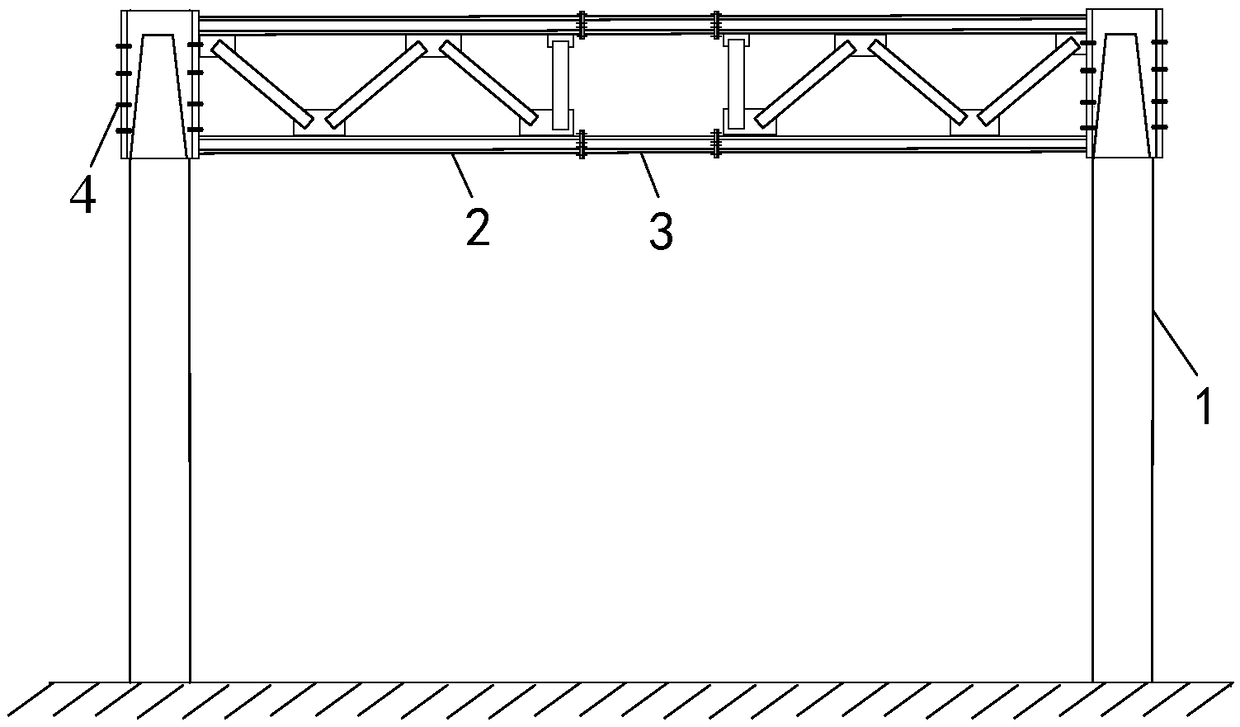

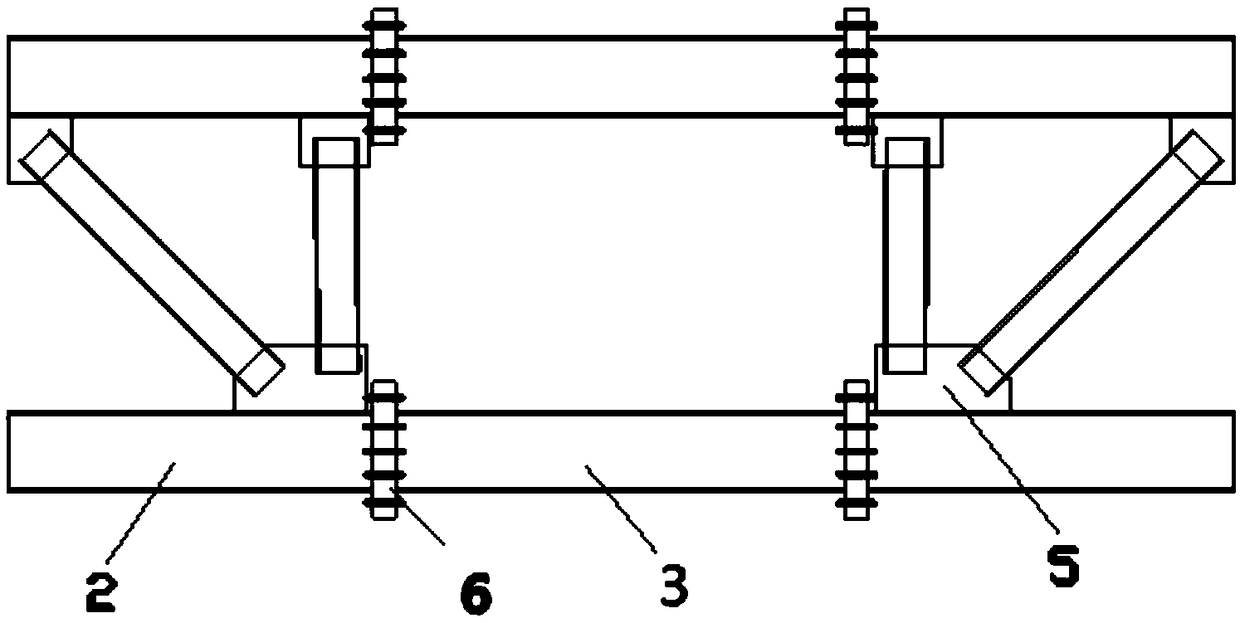

Multi-storey high-rise assembly type steel frame structure with replaceable open-web energy consumption segment

InactiveCN108978865AEasy to pass throughIncrease design spanCeilingsShock proofingButt jointEngineering

The invention discloses a multi-storey high-rise assembly type steel frame structure with a replaceable open-web energy consumption segment. The structure comprises a truss girder and frame columns for supporting both ends of the truss girder. The truss girder includes an energy consumption segment and a non-energy consumption segment; the energy consumption segment of the truss girder does not arrange a web member to be an open-web type, so that the energy consumption is concentrated; two ends of the energy consumption segments of the truss girder are in butt joint with one end of the non-energy consumption segment in a detachable manner so as to facilitate the replacement of the energy consumption segment after an earthquake, and the other end of the non-energy consumption segment of thetruss girder is mounted on the frame column; and a chord member of the energy consumption segment of the truss girder and the web member of the non-energy consumption segment of the truss girder aremade of common steel; and the chord member of the non-energy consumption segment of the truss girder, the frame columns and a node connecting sleeve plate are made of high-strength steel. The frame structure provided by the invention is formed by adoption of high-strength steel and common steel in a combined manner, not only keeps excellent energy consumption performance of common steel, but alsoexerts the advantages of high strength and material saving of high-strength steel, the self weight of the structure is effectively reduced and the earthquake action is reduced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

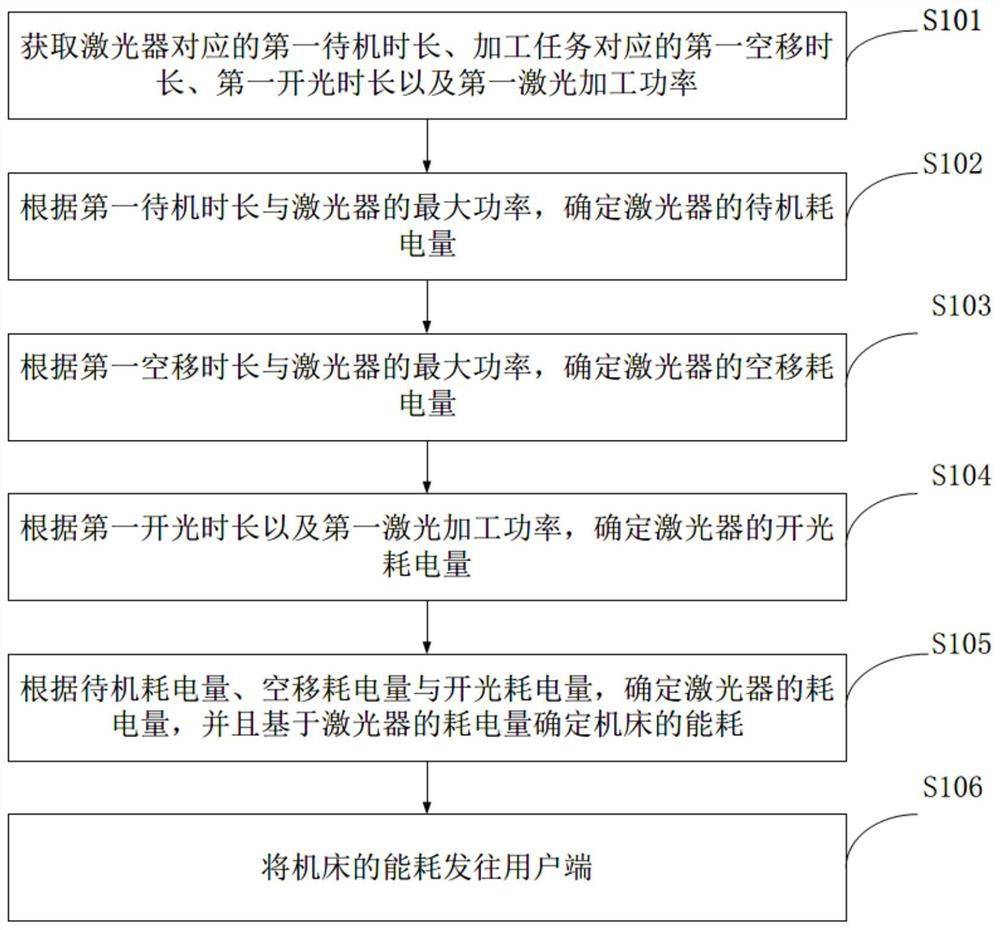

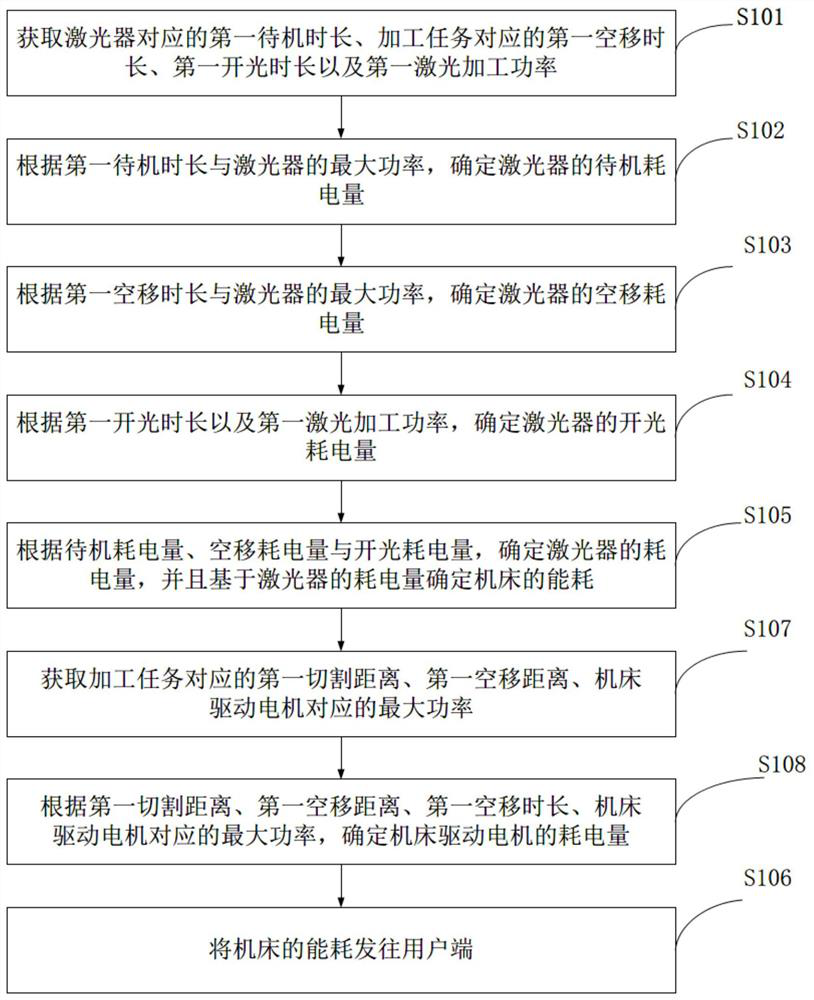

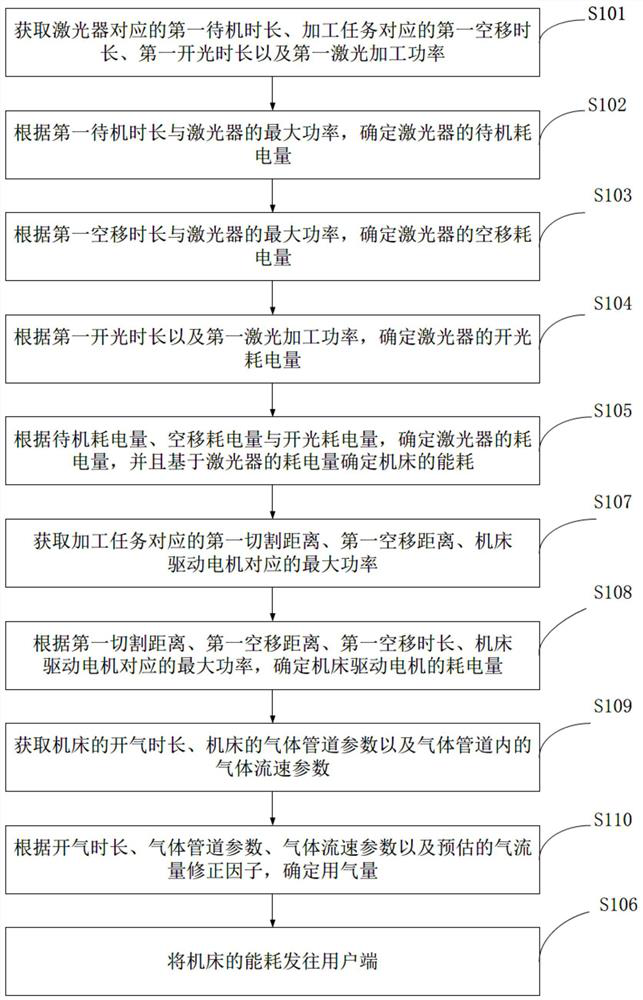

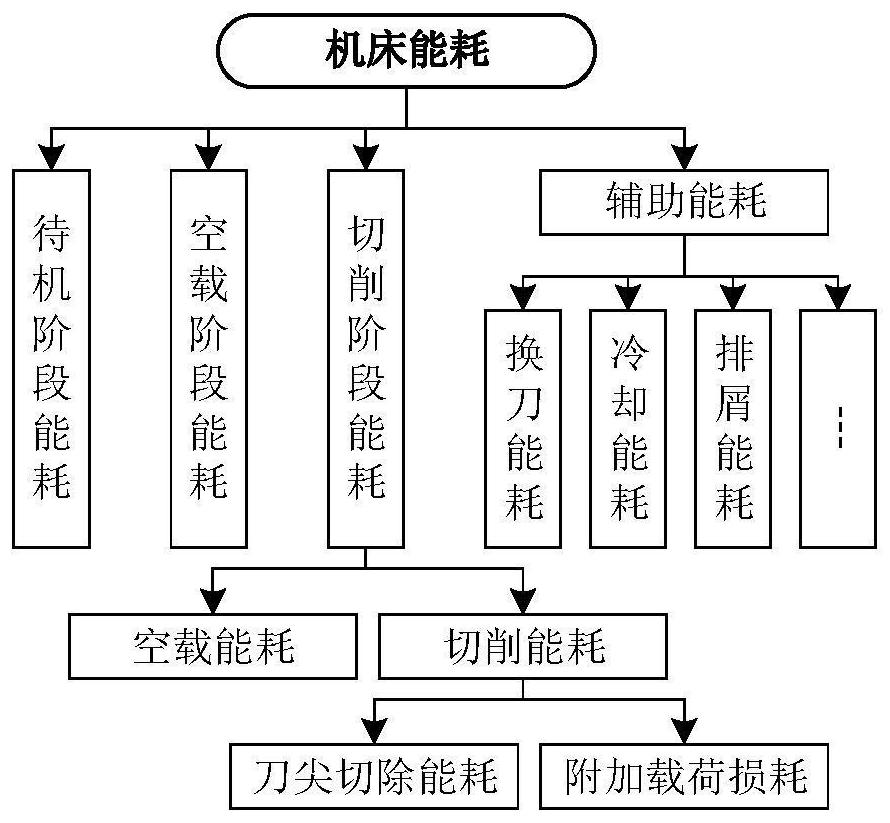

Energy consumption monitoring method, factor determination method, monitoring device, equipment and medium

ActiveCN111999552AAvoid energy consumptionLow costElectrical measurementsLaser processingStandby power

The invention provides an energy consumption monitoring method of a machine tool, a factor determination method, an energy consumption monitoring device of the machine tool, electronic equipment and astorage medium. The method is applied to a business server, the energy consumption of the machine tool comprises the power consumption of a laser, and the method comprises the following steps: obtaining a first standby duration corresponding to the laser, and a first idle shift duration, a first switching duration and a first laser processing power corresponding to a processing task; determiningstandby power consumption of the laser according to the first standby duration and the maximum power of the laser; determining the space-shift power consumption of the laser according to the first space-shift duration and the maximum power of the laser; determining the switching power consumption of the laser according to the first switching duration and the first laser processing power; determining the power consumption of the laser according to the standby power consumption, the idle moving power consumption and the switching power consumption, and determining the energy consumption of the machine tool based on the power consumption of the laser; and sending the energy consumption of the machine tool to a user side. The cost for obtaining the energy consumption of the machine tool can bereduced.

Owner:上海控软网络科技有限公司

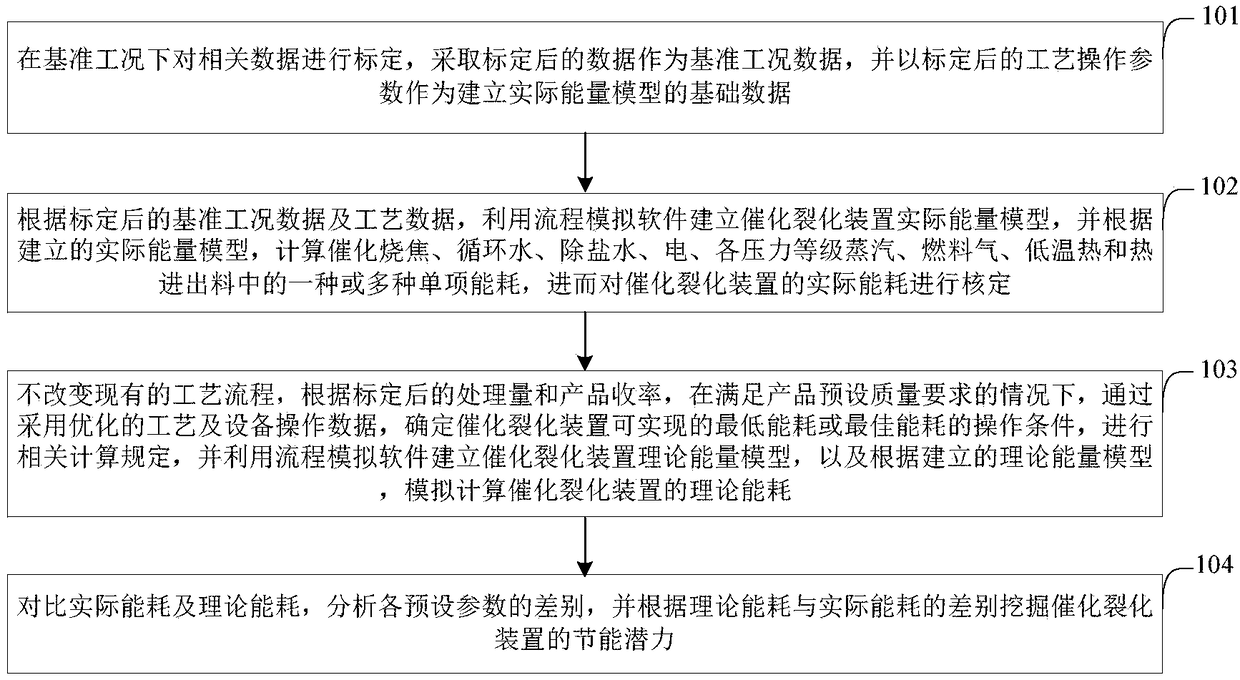

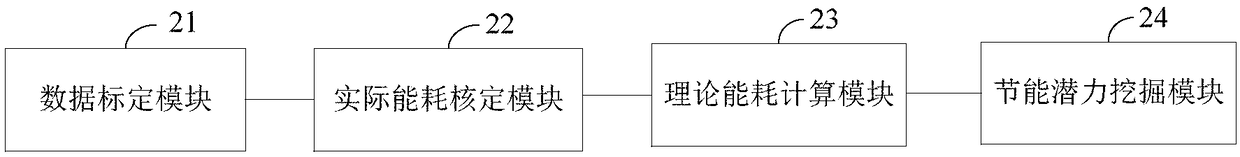

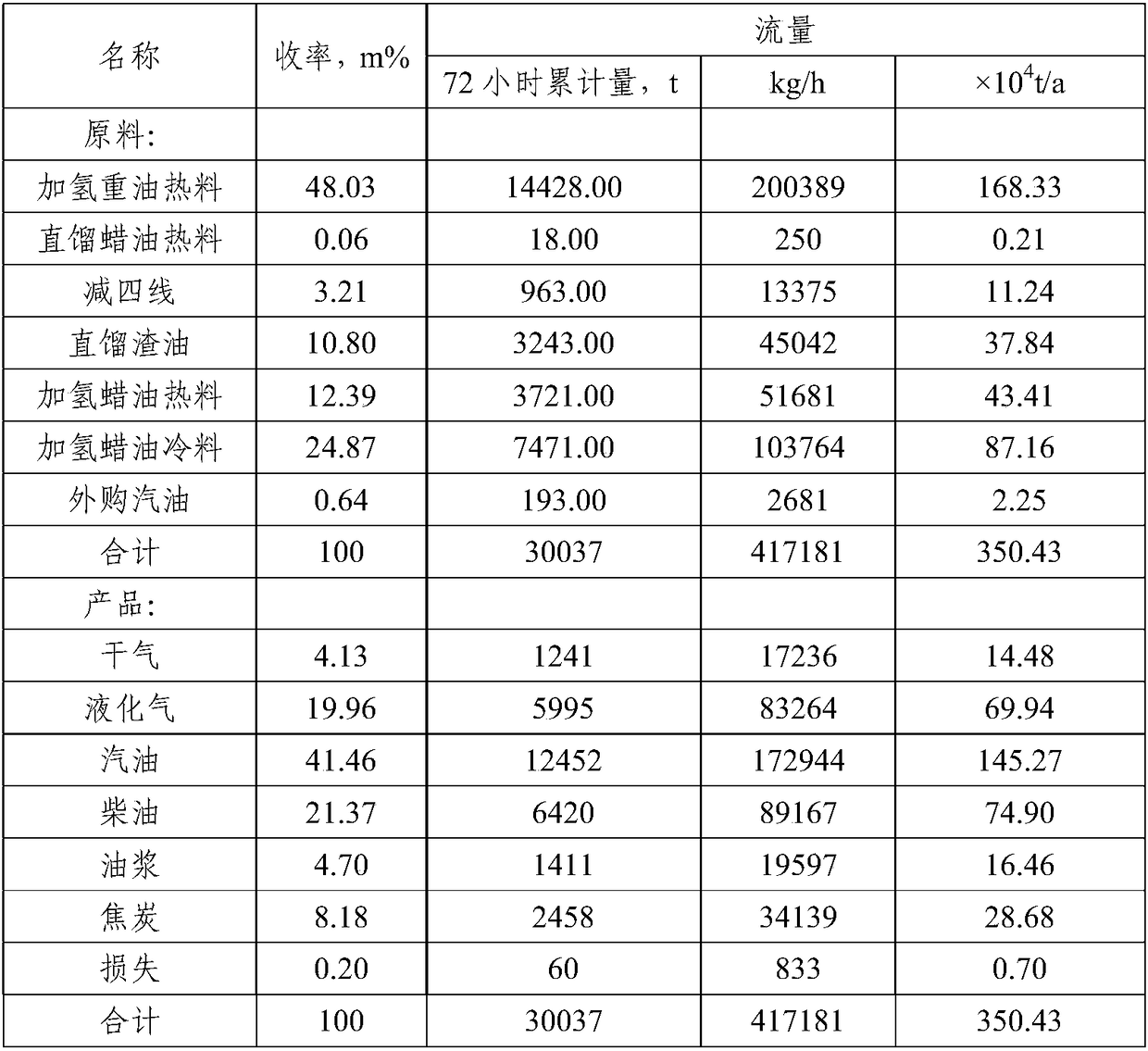

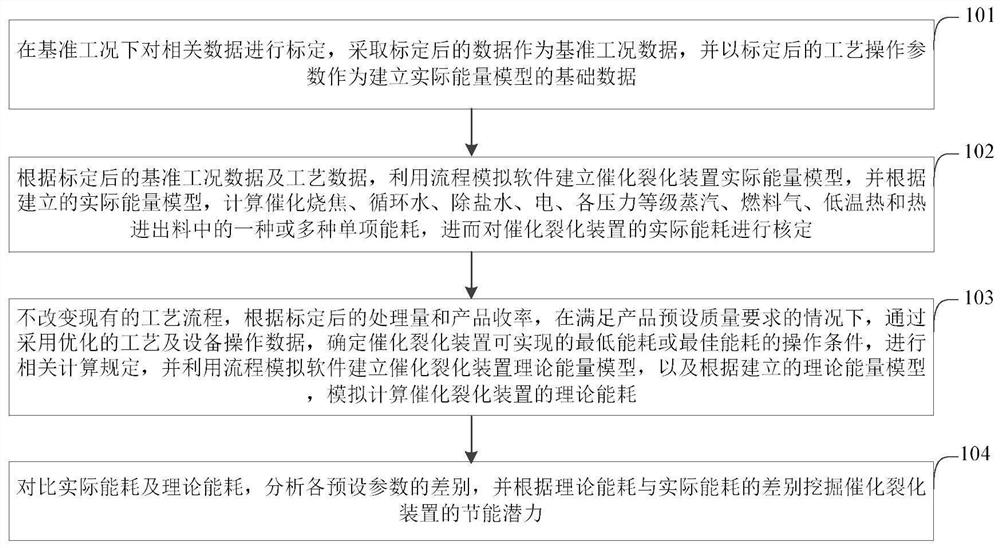

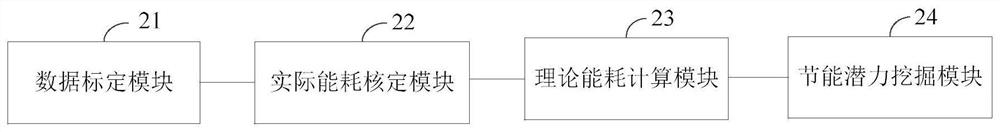

Catalytic-cracking energy use analysis method and device

ActiveCN109298655AAccurate Energy ConsumptionConducive to tapping energy-saving potentialProgramme controlComputer controlSimulationAnalysis method

The invention provides a catalytic-cracking energy use analysis method and device. The method comprises: establishing an actual energy model of a catalytic-cracking device according to benchmark working condition data and technology data after calibration, and verifying actual energy consumption of the catalytic-cracking device; determining an operation condition of minimum energy consumption which can be realized by the catalytic-cracking device through use of optimized technology and equipment operation data in a case, where a preset product quality requirement is met according to processingquantity and product yield after calibration without changing an existing technology process, carrying out relevant calculation regulation, establishing a theoretical energy model of the catalytic-cracking device, and carrying out simulation calculation on the theoretical energy consumption of the catalytic-cracking device; and mining energy saving potentials of the catalytic-cracking device through difference comparison of the actual energy consumption and the theoretical energy consumption. According to the method, firstly the lowest energy consumption which can be achieved theoretically bythe catalytic-cracking device can be obtained, then the theoretical minimum energy consumption can be compared with the actual energy consumption, and thus mining of the energy saving potentials of the catalytic-cracking device is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

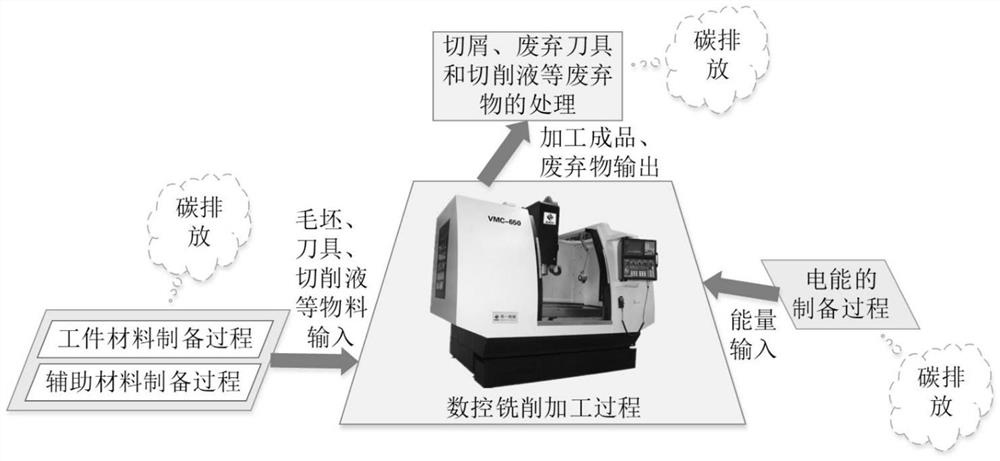

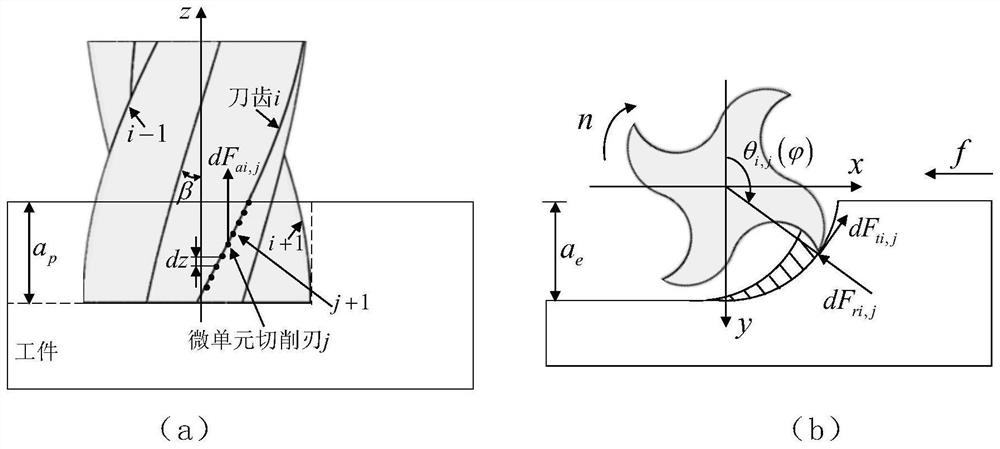

Milling process-oriented carbon emission chemical calculation method and system

PendingCN113704974AThe calculation result is accurateReal-time and accurate discharge flowDesign optimisation/simulationSpecial data processing applicationsProcess engineeringMachining process

The invention discloses a milling process-oriented carbon emission chemical calculation method and system. The method comprises the following steps: determining a total carbon emission boundary in a numerical control milling process; determining total carbon emission according to a total carbon emission boundary, and calculating material carbon and waste carbon by utilizing a material carbon and waste carbon evaluation method; establishing a micro-unit cutting force calculation model, constructing a milling machining cutting power calculation model through numerical integration derivation, and obtaining cutting power including average tool nose cutting power and machine tool additional load loss power in unit time through calculation; establishing a machine tool energy consumption model including no-load energy consumption, cutting energy consumption and auxiliary energy consumption, determining machine tool energy consumption according to the machine tool energy consumption model, and obtaining carbon emission generated by electric energy consumed by the numerical control machine tool in the numerical control milling machining process in the preparation process through calculation; and realizing carbon emission chemical calculation in the numerical control milling process by combining material carbon, waste carbon and energy carbon. Carbon emission quantitative calculation support is provided for follow-up cutter path and cutting parameter optimization.

Owner:XI AN JIAOTONG UNIV

An intelligent skipping rope and its control method

ActiveCN103801048BAccurate energy consumptionSkipping-ropesWireless transmissionManufacturing technology

The invention is suitable for the technical field of sports equipment manufacturing, and provides an intelligent skipping rope. The intelligent skipping rope comprises a handle and a rope body, and a control module, a sensor module, a wireless transmission module and a power supply module are further arranged inside the handle; the output end of the power supply module is connected with the input end of the control module; the output end of the sensor module is connected with the input end of the control module; the output end of the control module is connected with the input end of the wireless transmission module, and the control module is used for obtaining a motion curve according to motion parameters collected by the sensor module, obtaining motion consumed energy values according to the motion curve, and sending the motion parameters and the motion consumed energy values to an intelligent terminal through the wireless transmission module. According to the intelligent skipping rope, a more accurate algorithm different from a traditional mode is adopted for calculating calories, and the accurate amount of motion and accurate energy consumption can be accurately worked out in various motion modes.

Owner:SHENZHEN DO INTELLIGENT TECH CO LTD

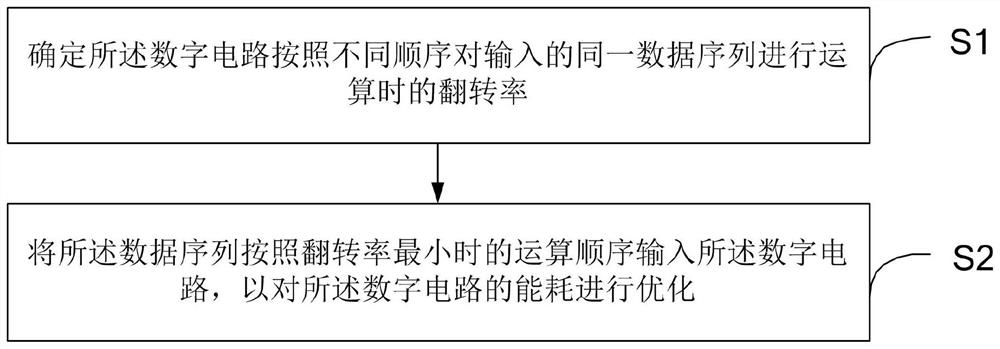

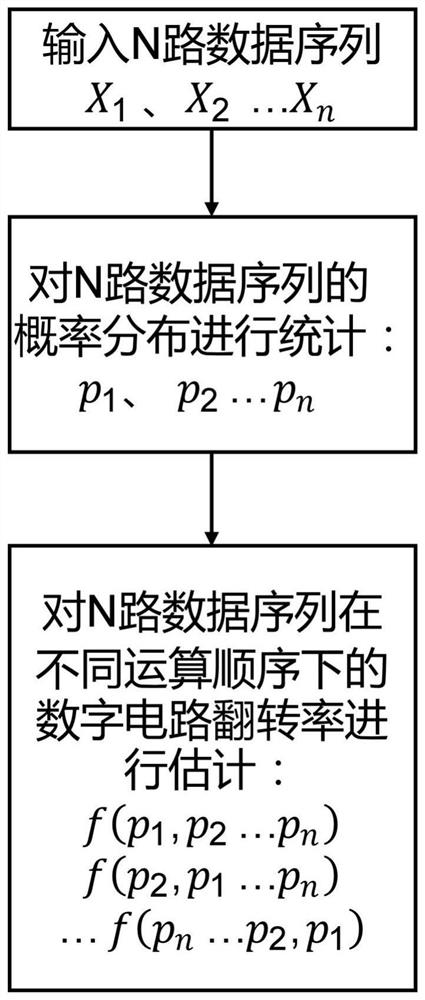

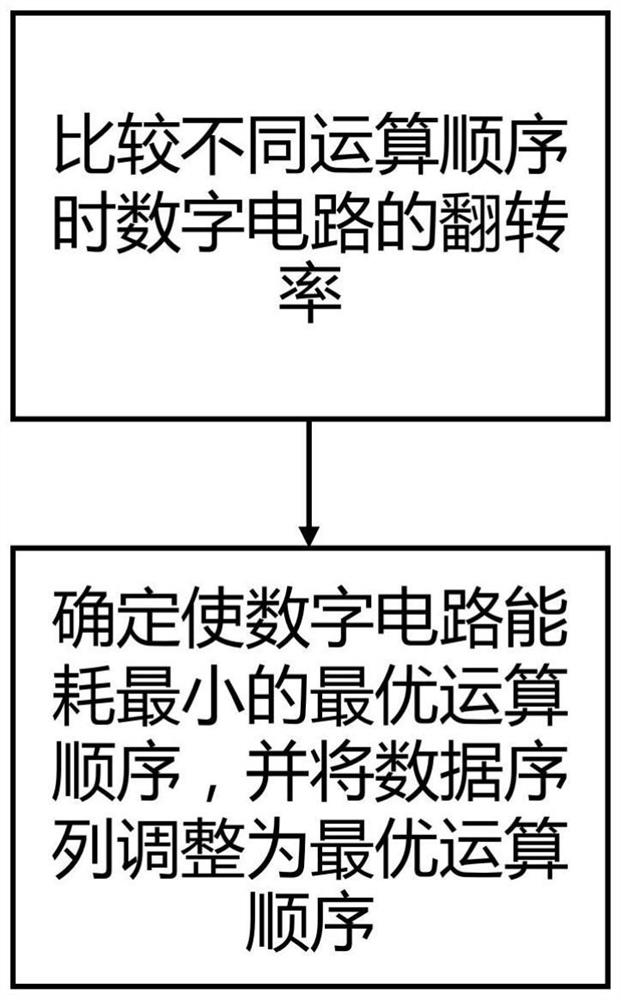

Digital circuit energy consumption optimization method

PendingCN114880976AAccurate Energy ConsumptionAccurate estimateComputer aided designSpecial data processing applicationsDynamical optimizationData sequences

The invention discloses a digital circuit energy consumption optimization method, which combines the characteristics that the energy consumption in a digital circuit mainly comes from dynamic energy consumption and the dynamic energy consumption is dominated by the flipping rate of the digital circuit, and considers that the flipping rate of the digital circuit is closely related to an actual input data sequence. And estimating the flipping rate of the digital circuit according to the probability distribution of the input data sequence, and taking the flipping rate as a basis for judging the energy consumption of the digital circuit. By analyzing the probability distribution of the data sequence, the energy consumption of the digital circuit can be accurately estimated, a data basis is provided for optimizing the operation sequence of the data sequence, and the operation sequence of the data sequence is dynamically optimized by estimating the flipping rate when the digital circuit inputs different operation sequences of the data sequence in real time. Therefore, the energy consumption of the digital circuit is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

viscoplastic hinge

ActiveCN108331176BAccurate energy consumptionSimple structureProtective buildings/sheltersShock proofingViscous liquidRotational axis

The invention relates to a viscous plastic hinge comprising an energy consumption unit, a limiting unit and a connecting assembly. The energy consumption unit is a cylinder and internally provided with a rotating shaft, a partition plate, a rotating plate and viscous liquid. The limiting unit consists of a limiting pin, a limiting plate and a left connecting plate. The connecting assembly includesconnecting plates and anchor plates. The rotating shaft, the rotating plate, the left connecting plate and the left anchoring plate form the left part of the viscous plastic hinge, and a cylindricalbox body, the partition plate, the limiting plate, the right connecting plate and the right anchoring plate form the right part of the viscous plastic hinge, after the limiting pin is cut off, the left part and right part can rotate relatively to each other. During normal use and small earthquakes, the limiting unit provides rotational rigidity, and the viscous plastic hinge is a rigid node. Whenmoderate and large earthquakes occur, the limiting pin is cut off, and the plastic hinge rotates relatively. When the rotating plate with a through hole rotates with the rotating shaft, the viscous liquid is forced to generate a certain flow velocity through the through hole in a short period of time to consume energy.

Owner:TONGJI UNIV

A catalytic cracking energy analysis method and device

ActiveCN109298655BAccurate Energy ConsumptionConducive to tapping energy-saving potentialProgramme controlComputer controlProcess engineeringEnergy consumption

The invention provides a catalytic-cracking energy use analysis method and device. The method comprises: establishing an actual energy model of a catalytic-cracking device according to benchmark working condition data and technology data after calibration, and verifying actual energy consumption of the catalytic-cracking device; determining an operation condition of minimum energy consumption which can be realized by the catalytic-cracking device through use of optimized technology and equipment operation data in a case, where a preset product quality requirement is met according to processingquantity and product yield after calibration without changing an existing technology process, carrying out relevant calculation regulation, establishing a theoretical energy model of the catalytic-cracking device, and carrying out simulation calculation on the theoretical energy consumption of the catalytic-cracking device; and mining energy saving potentials of the catalytic-cracking device through difference comparison of the actual energy consumption and the theoretical energy consumption. According to the method, firstly the lowest energy consumption which can be achieved theoretically bythe catalytic-cracking device can be obtained, then the theoretical minimum energy consumption can be compared with the actual energy consumption, and thus mining of the energy saving potentials of the catalytic-cracking device is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of diesel hydrogenation energy analysis method and device

ActiveCN109299836BConducive to tapping energy-saving potentialAccurate Energy ConsumptionTechnology managementResourcesControl engineeringProcess engineering

The invention provides a method and device for analyzing the energy consumption of diesel hydrogenation. The method includes: according to the calibrated benchmark working condition data and process data, the actual energy model of the diesel hydrogenation device is established and the actual energy consumption of the diesel hydrogenation device is calculated. Approval; do not change the existing process flow, according to the calibrated processing capacity and product yield, in the case of meeting the preset quality requirements of the product, by adopting the optimized process and equipment operation data, determine the achievable performance of the diesel hydrogenation unit The operating conditions of the lowest energy consumption, carry out relevant calculation regulations, establish the theoretical energy model of the diesel hydrogenation unit and simulate the theoretical energy consumption of the diesel hydrogenation unit; tap the energy saving of the diesel hydrogenation unit by comparing the difference between the actual energy consumption and the theoretical energy consumption potential. The present invention can firstly obtain the theoretically attainable minimum energy consumption of the diesel hydrogenation unit, and then compare the theoretically attainable minimum energy consumption with the actual energy consumption, thereby helping to tap the energy-saving potential of the diesel hydrogenation unit.

Owner:CHINA PETROLEUM & CHEM CORP +1

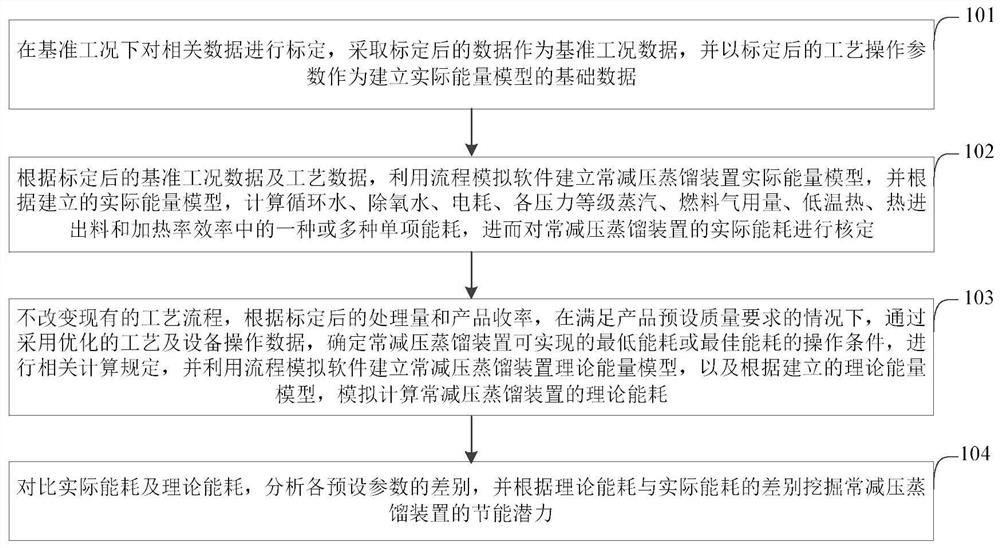

A method and device for analyzing energy consumption of atmospheric and vacuum distillation

ActiveCN109299483BAccurate Energy ConsumptionActual energy consumption complies withTechnology managementDesign optimisation/simulationProcess engineeringEnergy consumption

The invention provides a method and device for analyzing energy consumption of atmospheric and vacuum distillation. The method includes: establishing an actual energy model of the atmospheric and vacuum distillation device according to the calibrated benchmark working condition data and process data, and analyzing the actual energy consumption of the atmospheric and vacuum distillation device. The energy consumption is verified; without changing the existing process flow, according to the calibrated processing capacity and product yield, in the case of meeting the preset quality requirements of the product, by adopting the optimized process and equipment operation data, determine the atmospheric and vacuum distillation The operating conditions of the lowest energy consumption that the device can achieve, carry out relevant calculation regulations, establish the theoretical energy model of the atmospheric and vacuum distillation device and simulate and calculate the theoretical energy consumption of the atmospheric and vacuum distillation device; by comparing the difference between the actual energy consumption and the theoretical energy consumption, mining Energy saving potential of atmospheric and vacuum distillation units. The present invention can firstly obtain the theoretically attainable minimum energy consumption of the atmospheric and vacuum distillation device, and then compare the theoretically attainable minimum energy consumption with the actual energy consumption, thereby helping to tap the energy-saving potential of the atmospheric and vacuum distillation device .

Owner:CHINA PETROLEUM & CHEM CORP +1

Friction-plastic hinges and design methods for truss structures and frame structures

ActiveCN107724530BAccurate energy consumptionSimple structureBuilding constructionsEngineeringPlastic hinge

The invention relates to a friction plastic hinge suitable for a truss structure and a frame structure and a design method. The left side of an arc-shaped sealing plate is connected with a left chordmember, a lining plate is stuck on the right side of the arc-shaped sealing plate, a left connection plate is arranged in the middle of the lining plate, and a limit hole and a rotation hole are formed in the left connection plate; a circular-tube-shaped sealing plate is arranged on a right unit, the right side of the circular-tube-shaped sealing plate is connected with a right chord member, and afriction material is stuck on the left side of the circular-tube-shaped sealing plate; two right connection plates are arranged in the middle of the circular-tube-shaped sealing plate, and limit holes and rotation holes are formed in the right connection plates. The design method comprises the steps that 1, under the situation that a beam is normally used, the continuity is kept, and the outer surface of the friction material is tangent to a flange of the beam; 2, under the effect of the major earthquake, limit pin are preferentially cut off, the area sum of the limit pins is set to be smaller than that of rotation pins, and design parameters are determined by formulas.

Owner:兰州瑟百瑞减震技术开发有限公司

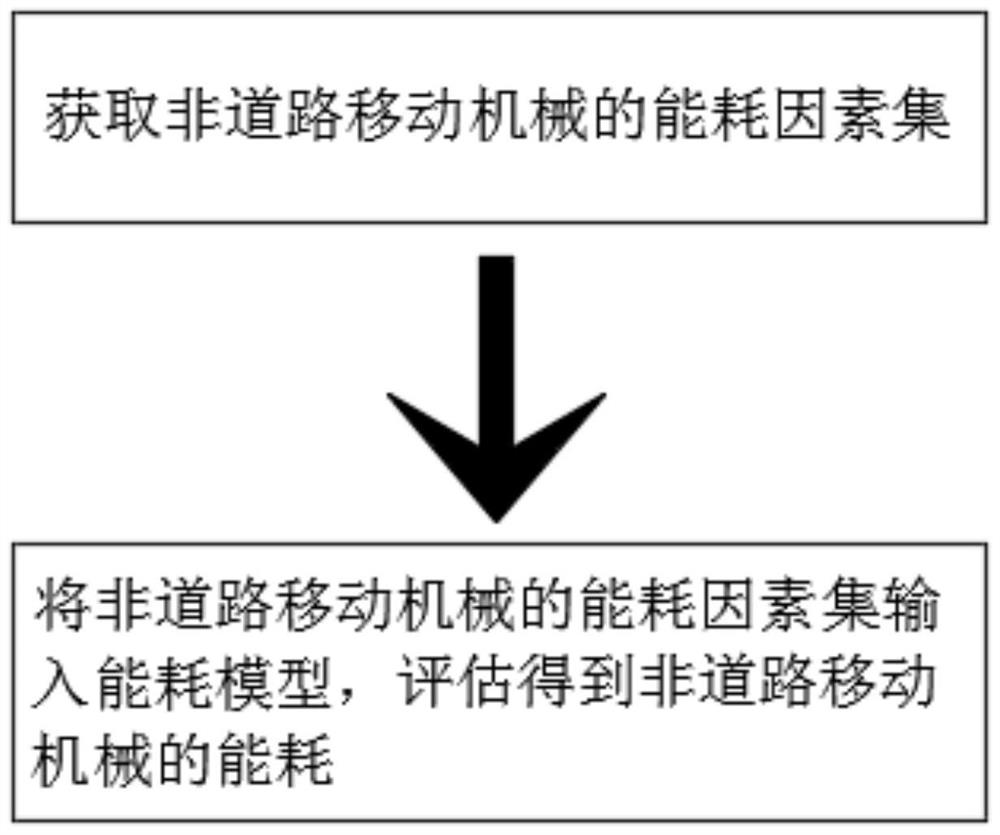

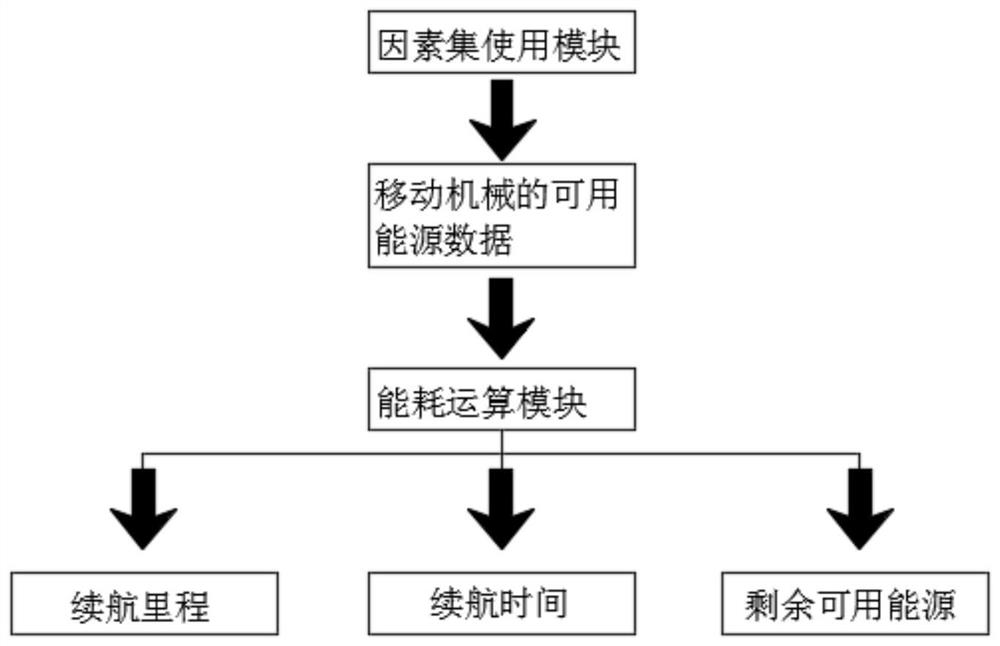

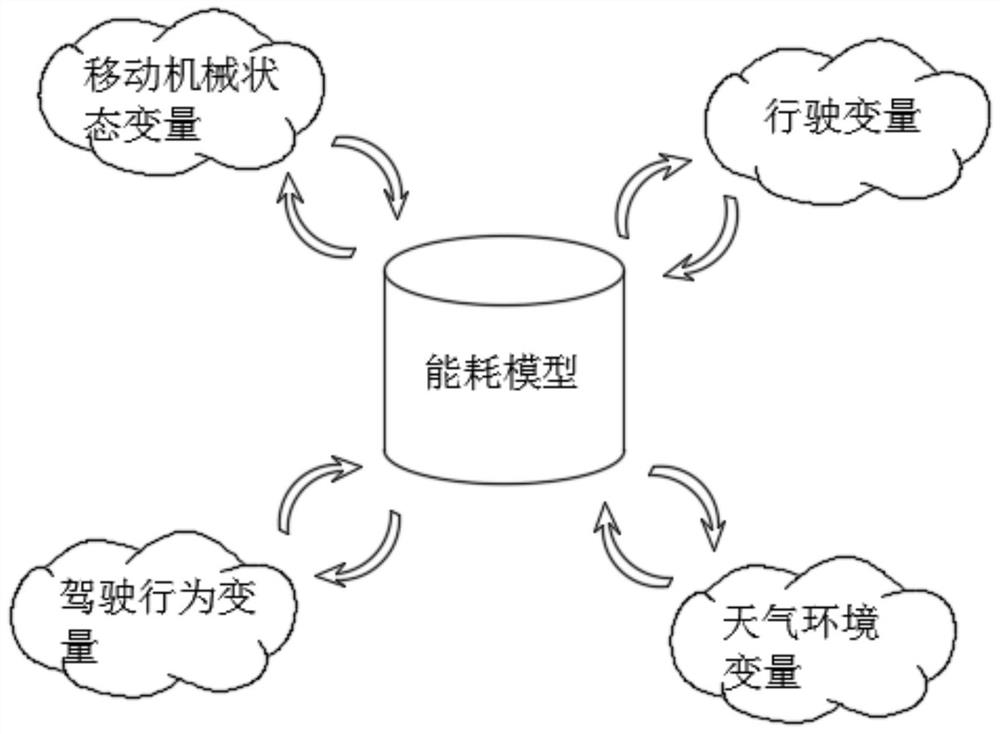

Method and equipment for evaluating energy consumption of non-road mobile machinery

PendingCN114282313AAccurate Energy ConsumptionIncrease profitGeometric CADMeasurement apparatus housingsEnergy consumptionReal-time computing

The invention discloses a method and equipment for evaluating the energy consumption of a non-road mobile machine, and the method comprises the following steps: obtaining an energy consumption factor set of the non-road mobile machine, the energy consumption factor set comprises a mobile machine state variable representing the use condition of each part in the mobile machine, a driving variable representing the driving state of the mobile machine, and a driving behavior variable representing the driving behavior of an operator, and inputting the energy consumption factor set of the non-road mobile machine into an energy consumption model, and evaluating to obtain the energy consumption of the non-road mobile machinery. According to the method, through execution of the operation steps, the effect of big data analysis is exerted, meanwhile, through setting, collection and use of the energy consumption factor set for the non-road mobile machinery, the energy consumption of the non-road mobile machinery is evaluated more accurately, the evaluation efficiency is greatly improved, the energy utilization rate is further improved, and the energy consumption of the non-road mobile machinery is reduced. The energy cost of enterprises can be saved, and the product competitiveness is improved.

Owner:北京蜂云科创信息技术有限公司

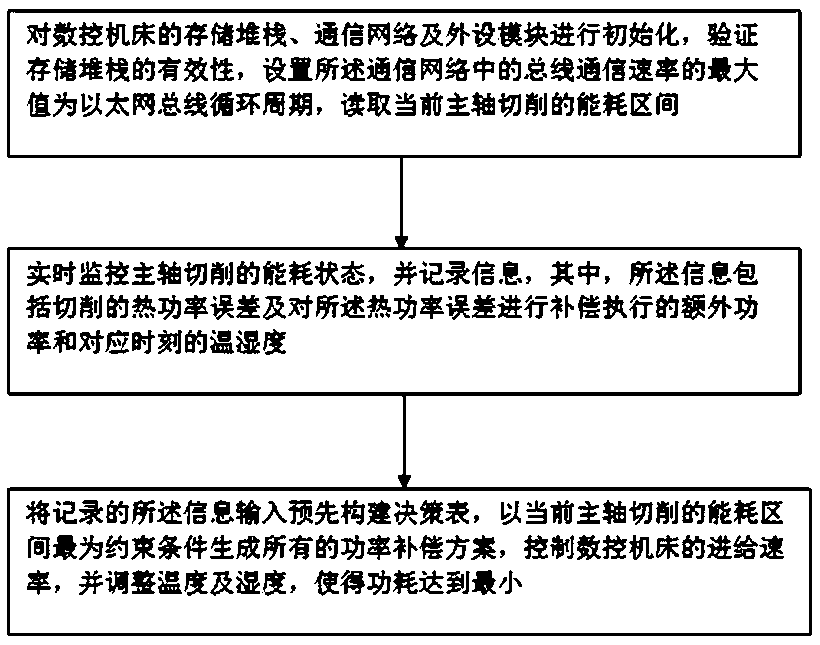

Numerical control machine tool control method based on energy consumption optimization and numerical control machine tool

InactiveCN110764464AAccurate Energy ConsumptionReduce energy consumptionProgramme controlComputer controlNumerical controlPower compensation

The invention discloses a numerical control machine tool control method based on energy consumption optimization. The method comprises the following steps that 1, a storage stack, a communication network and a peripheral module of a numerical control machine tool are initialized, the effectiveness of the storage stack is verified, the maximum value of the bus communication rate in the communication network is set as an Ethernet bus cycle period, and the energy consumption interval of current main shaft cutting is read; 2, the energy consumption state of main shaft cutting is monitored in realtime, and information is recorded, wherein the information comprises a cutting thermal power error, additional power for performing compensation execution on the thermal power error and the temperature and humidity at the corresponding moment; and 3, the recorded information is input into a pre-constructed decision table, all power compensation schemes are generated with the energy consumption interval of current main shaft cutting as the constraint condition, the feeding rate of the numerical control machine tool is controlled, the temperature and humidity are adjusted, and therefore the power consumption is minimum.

Owner:HONGHE COLLEGE +1

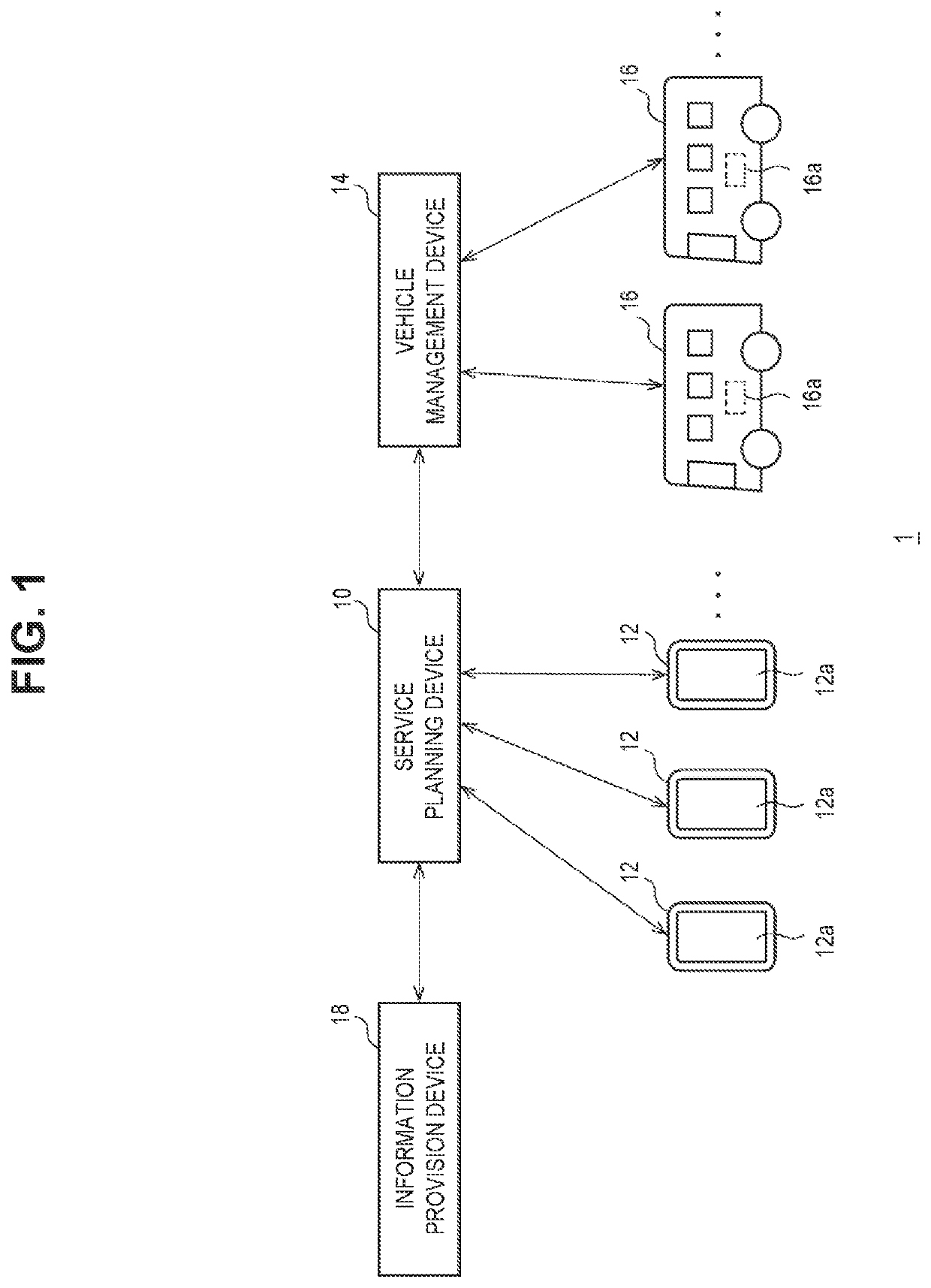

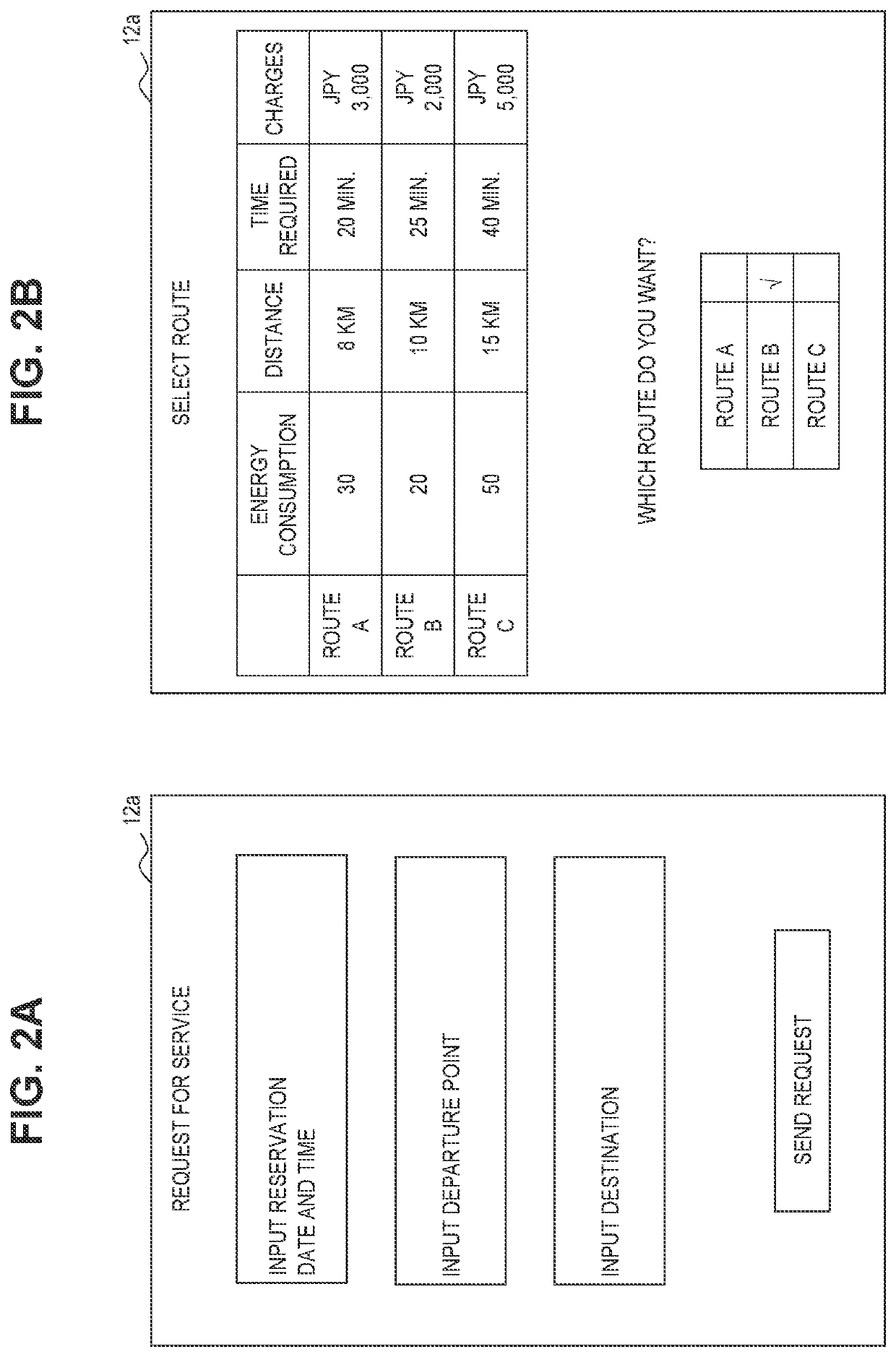

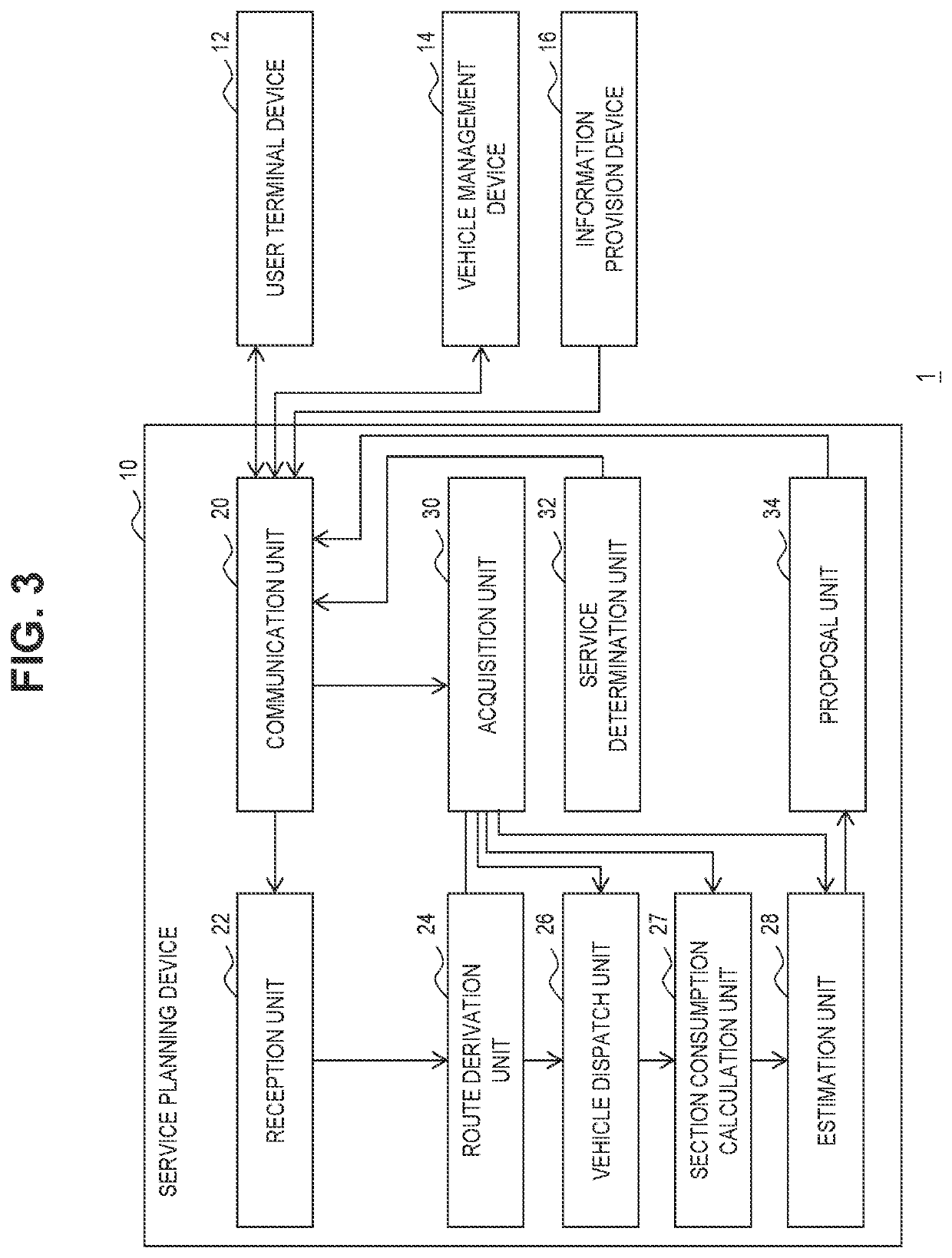

Energy consumption estimation device and energy consumption estimation method

PendingUS20220214691A1Accurate estimateAccurate Energy ConsumptionEnergy saving arrangementsRoad vehicles traffic controlSimulationTransport engineering

An energy consumption estimation device includes a reception unit configured to receive, from a user, request information including a departure point and a destination, a route derivation unit configured to derive a plurality of travel routes based on the departure point and the destination included in the request information, an acquisition unit configured to acquire section energy consumption in a case where a vehicle travels on a road section, which is derived based on information on vehicle speed and information on road undulations, and an estimation unit configured to respectively estimate energy consumption of the vehicle in a case where the vehicle travels on the derived travel routes by adding section energy consumption for road sections included in the travel route.

Owner:TOYOTA JIDOSHA KK

System and method for on-line monitoring energy consumption cost of spiral feeding type small-sized steam boiler

ActiveCN102141243BAccurate Energy ConsumptionExact costBoiler indication operationsBoiler controlLower limitPower flow

The invention discloses a system and a method for monitoring energy consumption cost of a spiral feeding type small-sized steam boiler on line, which can acquire energy consumption and cost data of the boiler in time, accurately calculate single-circle energy consumption cost and unit steam energy consumption cost and provide a basis for the improvement on the average operating efficiency of the boiler so as to achieve an energy-saving effect. In the system, a steam flow instrument, a fuel using amount monitoring device, an electricity meter and a water power flow instrument are in communication connection with a computer, so that the energy consumption cost of the boiler can be conveniently measured; the energy consumption cost is reduced to the lowest limit by reasonably adjusting the operating condition and the fuel of the boiler through the energy consumption and cost data which is monitored in real time by the system; simultaneously, all parameters are monitored on line, data acquisition and calculation processes are finished by the computer, and the authenticity of the data is reflected; and the on-line monitoring method provides in-time and accurate energy consumption data and technical indexes for the operation of the boiler.

Owner:湖南兆丰新能源技术有限公司

A hydrocracking energy analysis method and device

ActiveCN109299482BReduce energy consumptionConducive to tapping energy-saving potentialTechnology managementHydrocarbon oil crackingProcess engineeringEnergy consumption

The present invention provides a hydrocracking energy consumption analysis method and device. The method includes: establishing the actual energy model of the hydrocracking unit according to the calibrated benchmark working condition data and process data, and analyzing the actual energy consumption of the hydrocracking unit. Approval; do not change the existing process flow, according to the calibrated processing capacity and product yield, in the case of meeting the preset quality requirements of the product, by adopting the optimized process and equipment operation data, determine the achievable performance of the hydrocracking unit The operating conditions of the lowest energy consumption, carry out relevant calculation regulations, establish the theoretical energy model of the hydrocracking unit and simulate the theoretical energy consumption of the hydrocracking unit; tap the energy saving of the hydrocracking unit by comparing the difference between the actual energy consumption and the theoretical energy consumption potential. The present invention can firstly obtain the theoretically attainable minimum energy consumption of the hydrocracking unit, and then compare the theoretically attainable minimum energy consumption with the actual energy consumption, thereby helping to tap the energy-saving potential of the hydrocracking unit.

Owner:CHINA PETROLEUM & CHEM CORP +1

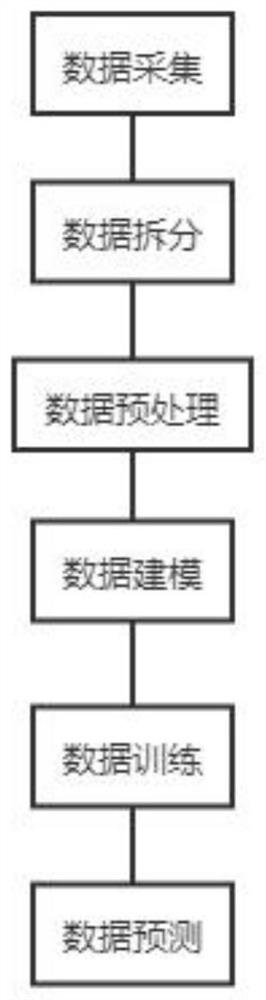

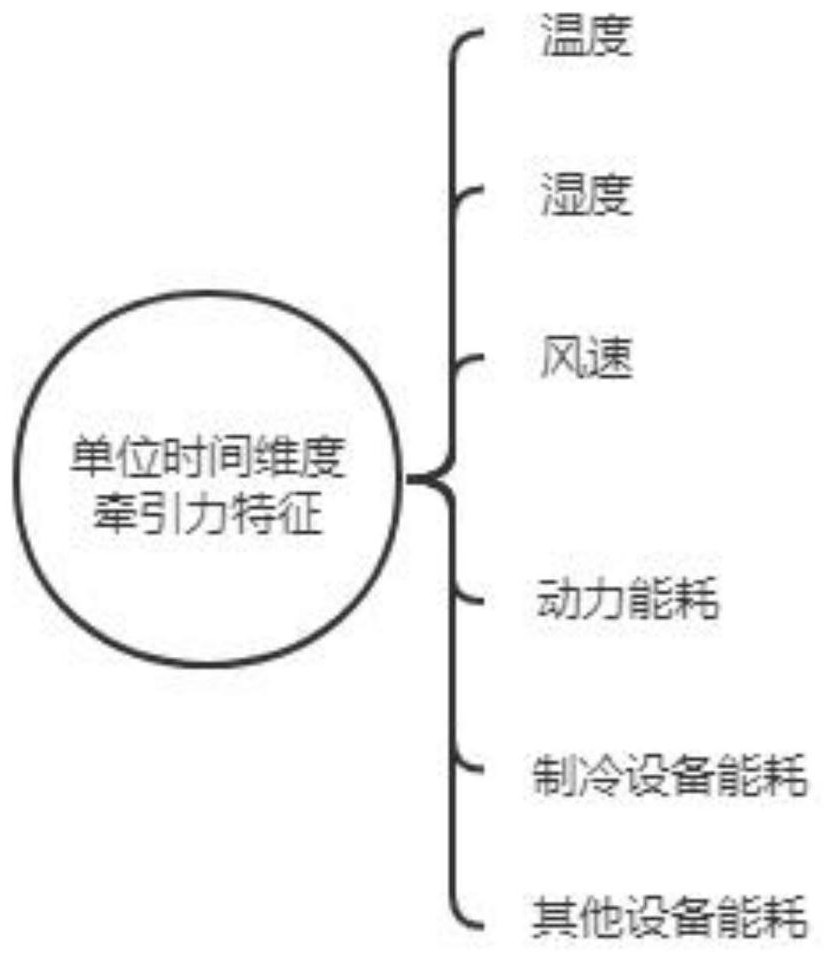

Multi-dimensional data-based traction energy consumption reasonable interval prediction method

PendingCN113822473AEnsure timeliness and accuracyGuaranteed real-timeGeometric CADForecastingData classData science

The invention discloses a multi-dimensional data-based traction energy consumption reasonable interval prediction method, which comprises the following steps: carrying out data acquisition: acquiring historical and real-time multi-dimensional characteristic data of energy consumption of an energy system; splitting the data, namely splitting the data into multi-dimensional data of different single items according to the difference of data types; carrying out data preprocessing: performing data preprocessing on the multi-dimensional data of each single item; carrying out data modeling: designing a data model for each piece of single-item multi-dimensional data; carrying out data training: training the established data model, and optimizing the data model; and carrying out data prediction: performing data prediction on real-time data according to the trained and optimized data model. According to the invention, interval prediction is carried out on multi-dimensional traction energy consumption data in the smart urban rail through an artificial intelligence algorithm and a distributed frame structure, multi-step prediction can be carried out according to historical data and real-time data, and auxiliary guidance is provided for traction equipment decision making.

Owner:ZHEJIANG SUPCON INFORMATION TECH CO LTD

Device, system and method for estimating the energy expenditure of a person

ActiveUS11160499B2Less complexAccurate energy consumptionSensorsMeasuring/recording heart/pulse rateEnergy expenditureIntensive care medicine

The present invention relates to a device for accurately estimating the energy expenditure of a person, in particular by which the effect of cardiovascular drift is taken into account. The device comprises an input unit (10) for obtaining a movement signal (13) representing physical activity of the person and a heart rate signal (15) representing the heart rate of the person, a cardiovascular drift determination unit (16) for determining cardiovascular drift phases (17) from said movement signal (13) and either said heart rate signal (15) and / or one or more cardiovascular drift related signals (23) carrying information on one or more of amount of sweat, weight loss, temperature rise, blood lactate concentration and physical fatigue of the person, a correction unit (18) for correcting the heart rate signal (15) generated and representing the heart rate during a cardiovascular drift phase, and an estimation unit (20) for estimating the energy expenditure of the person from the corrected heart rate signal (19).

Owner:KONINKLJIJKE PHILIPS NV

Electric vehicle average energy consumption prediction method and device

ActiveCN112810614BAccurate Energy ConsumptionAccurate calculation of actual energy consumptionElectric devicesOperating modesVehicle miles of travelElectric vehicle

The embodiments of the present invention provide a method for predicting average energy consumption of electric vehicles and a device for predicting average energy consumption of electric vehicles, which relate to the technical field of electric vehicles. The method includes: according to the real-time voltage and real-time current of the battery pack of the electric vehicle, determining the actual energy consumption of the traveled mileage segment corresponding to the current moment of the electric vehicle, where the traveled mileage segment includes a plurality of unit mileage segments; The actual energy consumption per unit mileage segment determines the initial average energy consumption of electric vehicles at the current moment; obtains the target average energy consumption and average energy consumption adjustment parameters of electric vehicles; adjusts according to the initial average energy consumption, target average energy consumption, and average energy consumption parameter to determine the actual average energy consumption of electric vehicles at the current moment. The invention can accurately calculate the actual average energy consumption of the electric vehicle at the current moment in real time.

Owner:GREAT WALL MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com