viscoplastic hinge

A plastic hinge and viscous technology, applied in the field of viscous plastic hinges, can solve the problems of high cost, affecting the structural bearing capacity, difficult to repair, etc., and achieve the effect of low cost, simple structure and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

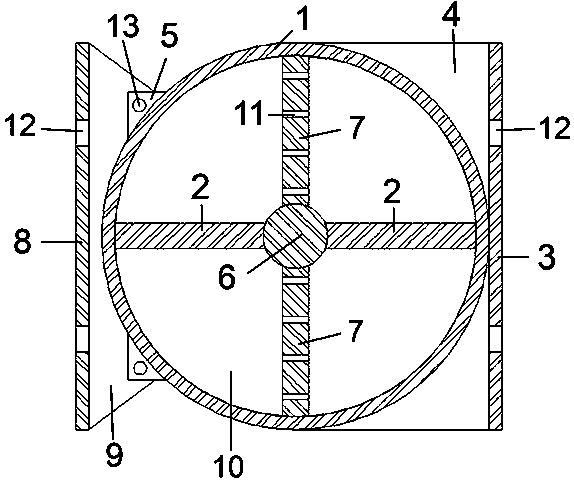

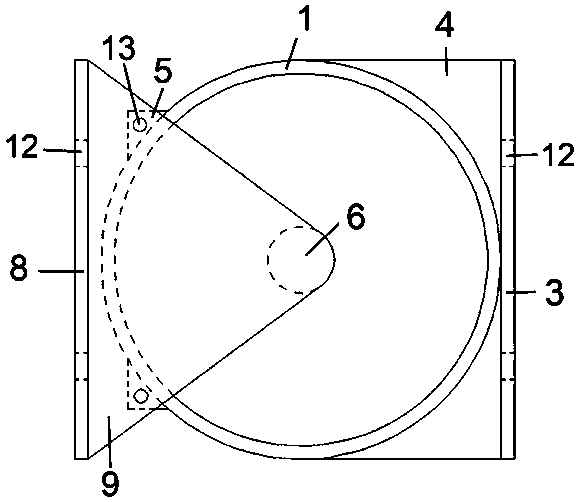

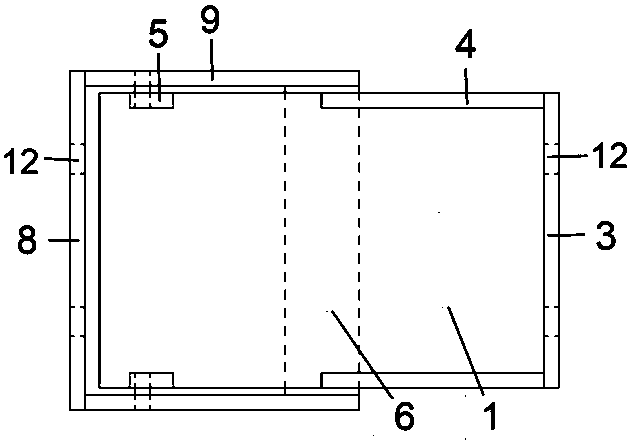

[0024] Embodiment 1: as figure 1 As shown, it is a viscous plastic hinge embodiment of the present invention, which mainly includes a cylindrical box 1, a partition plate 2, a right anchor plate 3, a right connecting plate 4, a limit plate 5, a rotating shaft 6, a rotating Plate 7, left anchor plate 8 and left connecting plate 9.

[0025] The cylindrical box body 1 is made of welded steel plates, and two partition plates 2 are symmetrically welded on the inside of the box body to separate the inside of the box body into upper and lower parts, and the upper and lower parts of the box body are filled with viscous liquid; A rotating plate 7 with several circulation holes 11 is symmetrically welded on the rotating shaft 6. When the viscous plastic hinge rotates relative to each other, the rotating plate 7 can rotate together with the rotating shaft 6; the limiting unit is connected by the limiting plate 5, left The plate 9 and the limit pin 13 are composed, the limit plate 5 is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com