Friction plastic hinge structure capable of controlling energy dissipation

A technology of plastic hinge and structure, which is applied in building structure, building components, earthquake resistance, etc., can solve the problems of precise control of energy consumption of difficult structures, plastic hinge damage, and difficulty in realization, and achieves simple structure, precise energy consumption, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

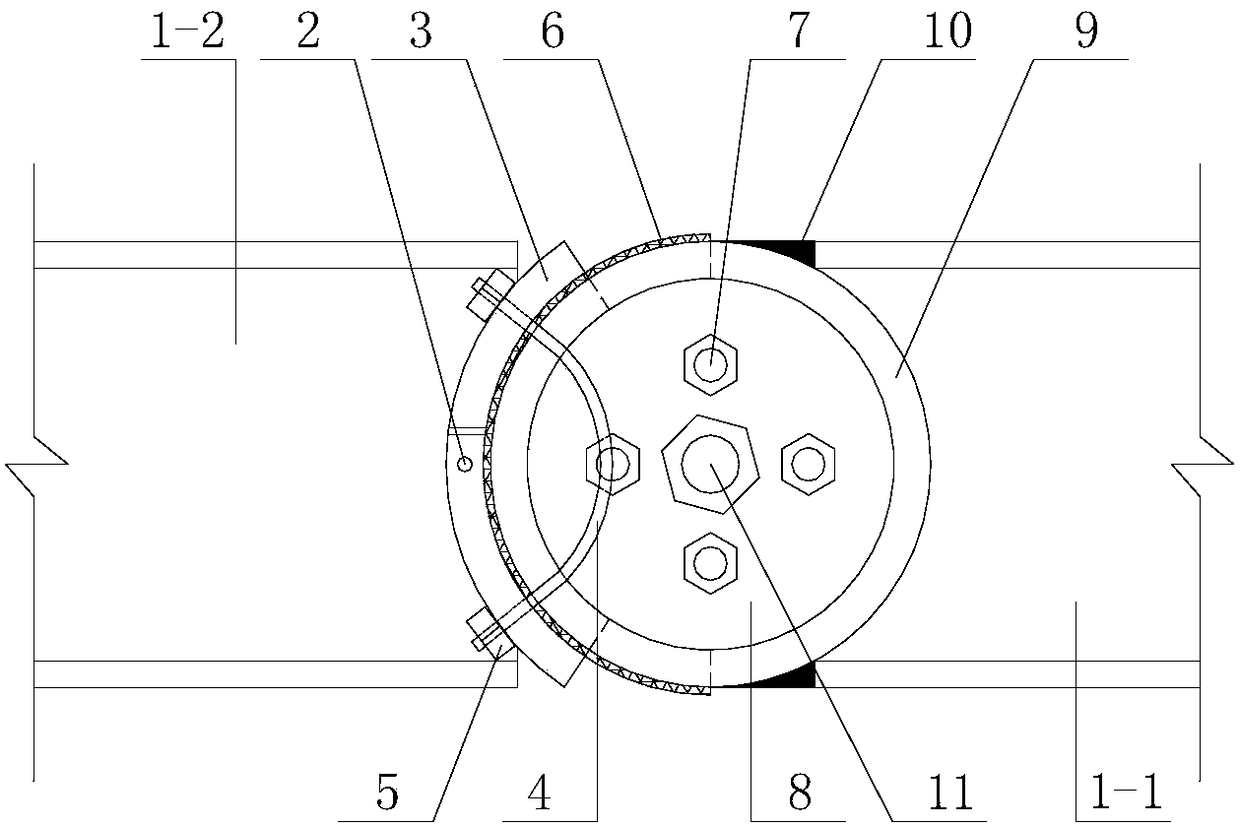

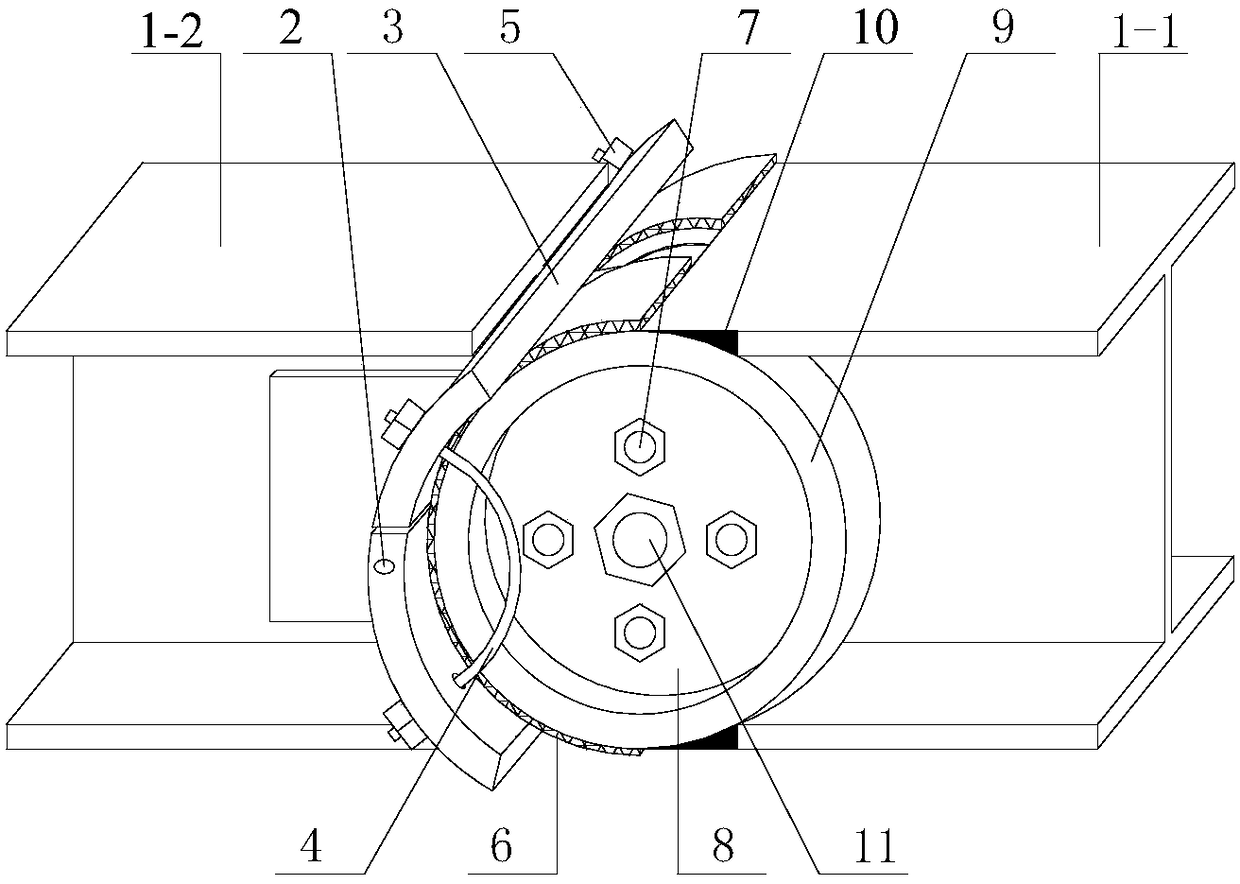

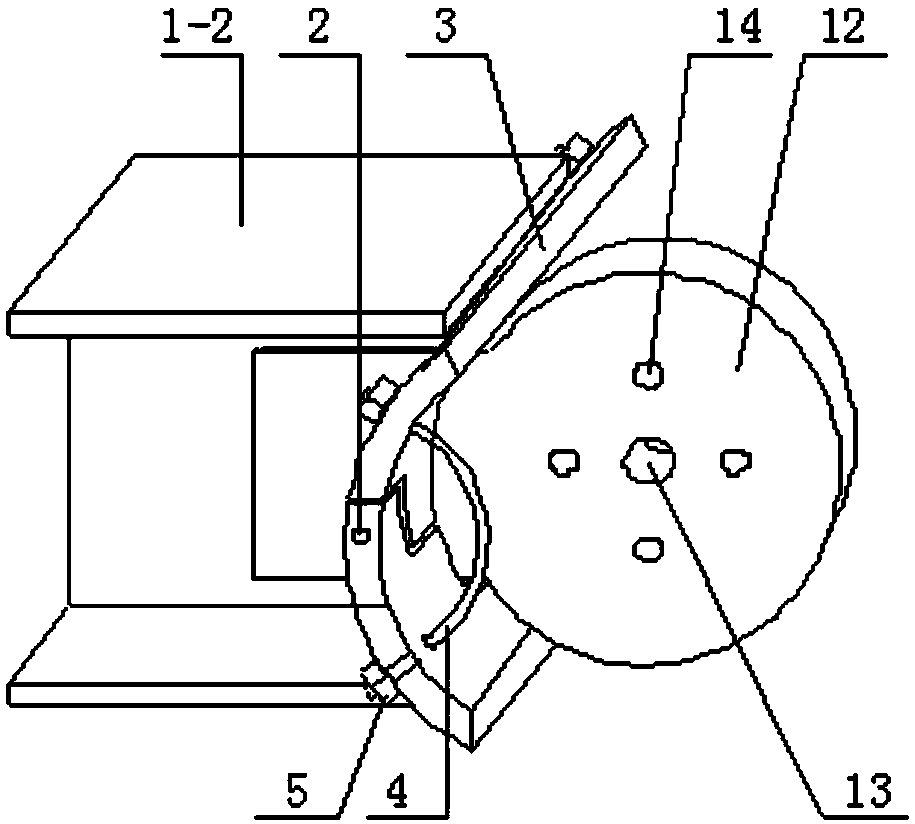

[0011] Such as Figure 1 ~ Figure 4 As shown, the present invention is a friction-plastic hinge structure with controllable energy consumption, which includes two parts: a rotating unit and a basic supporting unit. Hoop loading screw 4, hoop nut 5, and rotating single connecting plate 12 are formed, wherein the steel beam 1-2 is connected with rotating single connecting plate 12, and the upper and lower plates of arc-shaped loading plate 3 and rotating single connecting plate 12 are formed by rotating The pin 2 is connected, the hoop loading screw 4 and the arc-shaped loading plate 3 are bolted by the hoop nut 5; the basic support unit is composed of a steel beam 1-1, friction material 6, double connecting plate 8, and a round tube sealing plate 9, wherein the profiled steel beam 1-1 is connected to the circular tube-shaped sealing plate 9, the double connecting plate 8 is connected to the inner wall of the circular tube-shaped sealing plate 9, and the friction material 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com