Friction-plastic hinges and design methods for truss structures and frame structures

A technology of frame structure and truss structure, which is applied in the direction of building structure and construction, can solve the problems of plastic hinge damage, irreparable, difficult to realize, etc., and achieve the effect of reducing impact, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

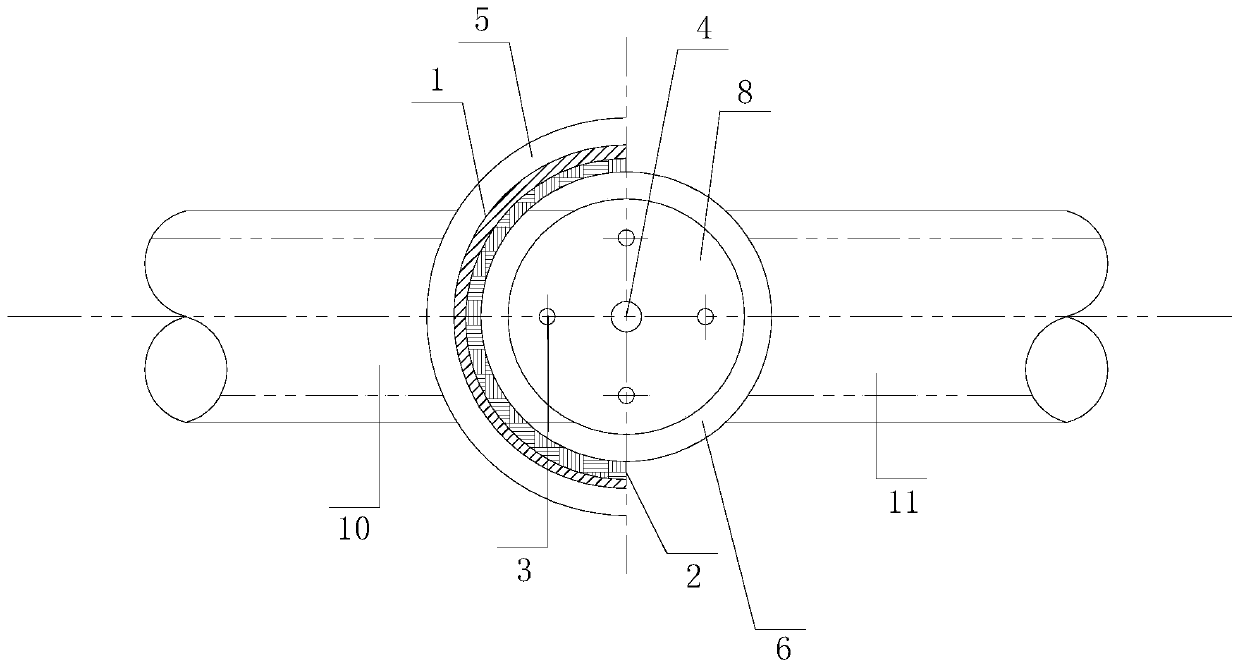

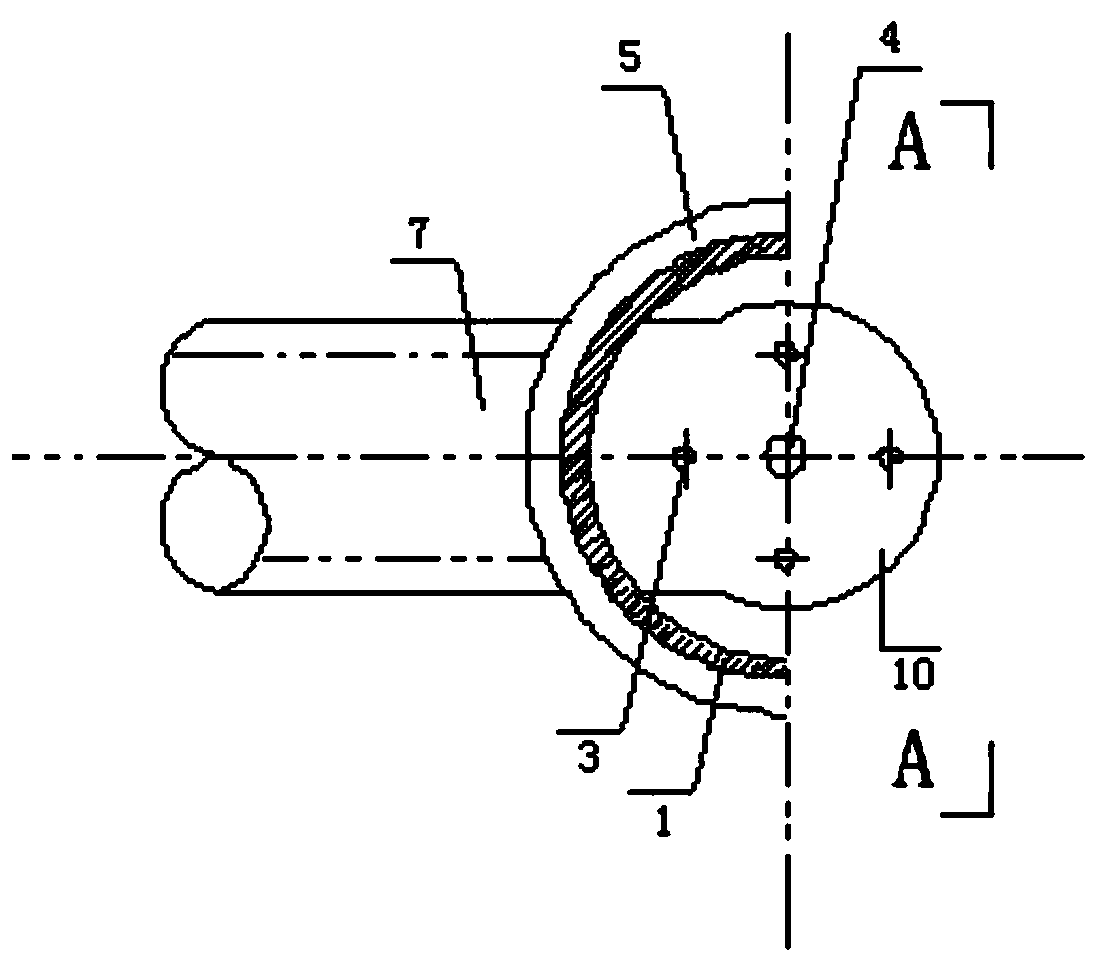

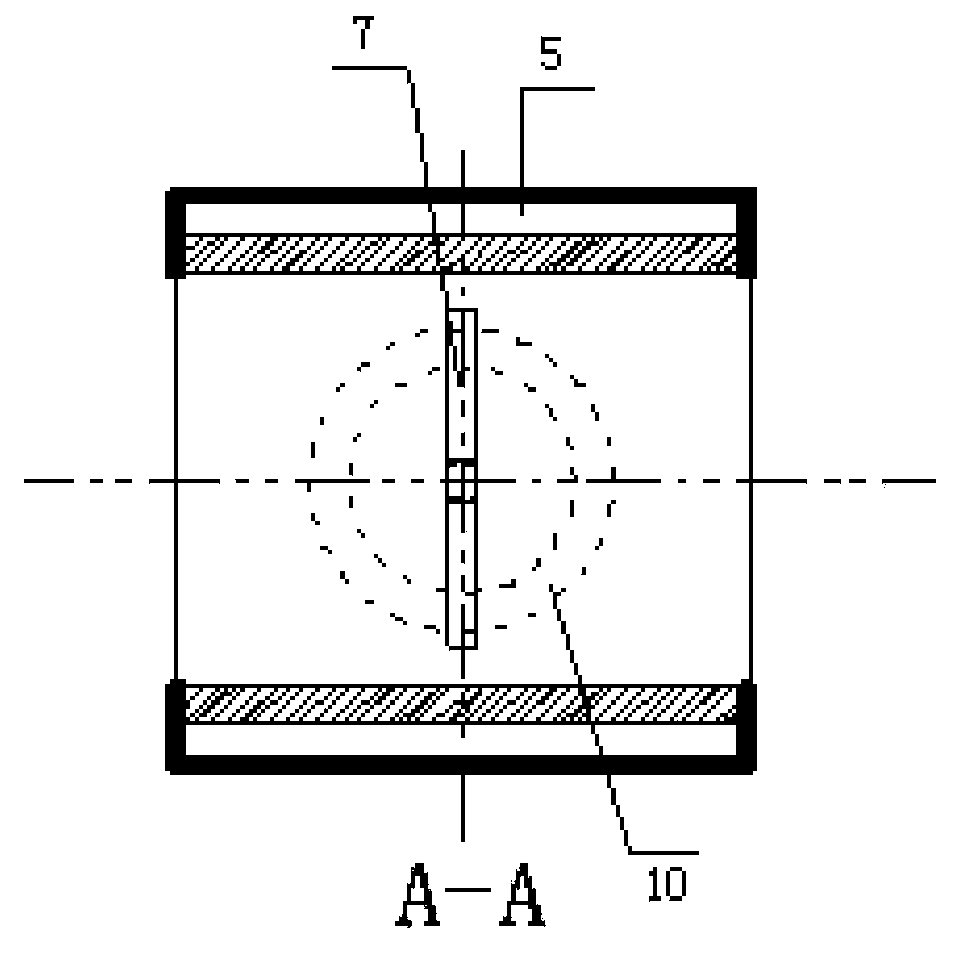

[0037] Such as figure 1 As shown, the present invention is based on the energy dissipation principle of the friction pendulum shock-isolation bearing, and is designed in combination with the construction method of the automobile braking device. The mechanism consists of three parts: the left unit, the right unit and the connecting unit. The left unit has an arc-shaped sealing plate 5, the left side is welded with the chord 7, the right side is pasted with a lining plate 1, the middle part of the lining plate is welded with a left connecting plate 10, and the left connecting plate 10 has a limit hole and a rotation hole . The right unit has a circular tube-shaped sealing plate 6, the right side is welded to the chord 11, the left side is pasted with friction material 2, and the middle part of the sealing plate is welded with two right connecting plates 8, 9, and the right connecting plates 8, 9 are Limited holes and rotating holes. The connector unit has four stop pins 3 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com