Connecting rod-piston mounting arrangement for reciprocating compressor of small refrigeration systems

A technology of refrigeration system and assembly structure, applied in mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problems of wear and tear, extremely difficult connection between the sphere and the end of the connecting rod in a high-quality and reliable way, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The type of the connecting rod-piston structure of the present invention working in the reciprocating compressor of the small refrigeration system will be described below.

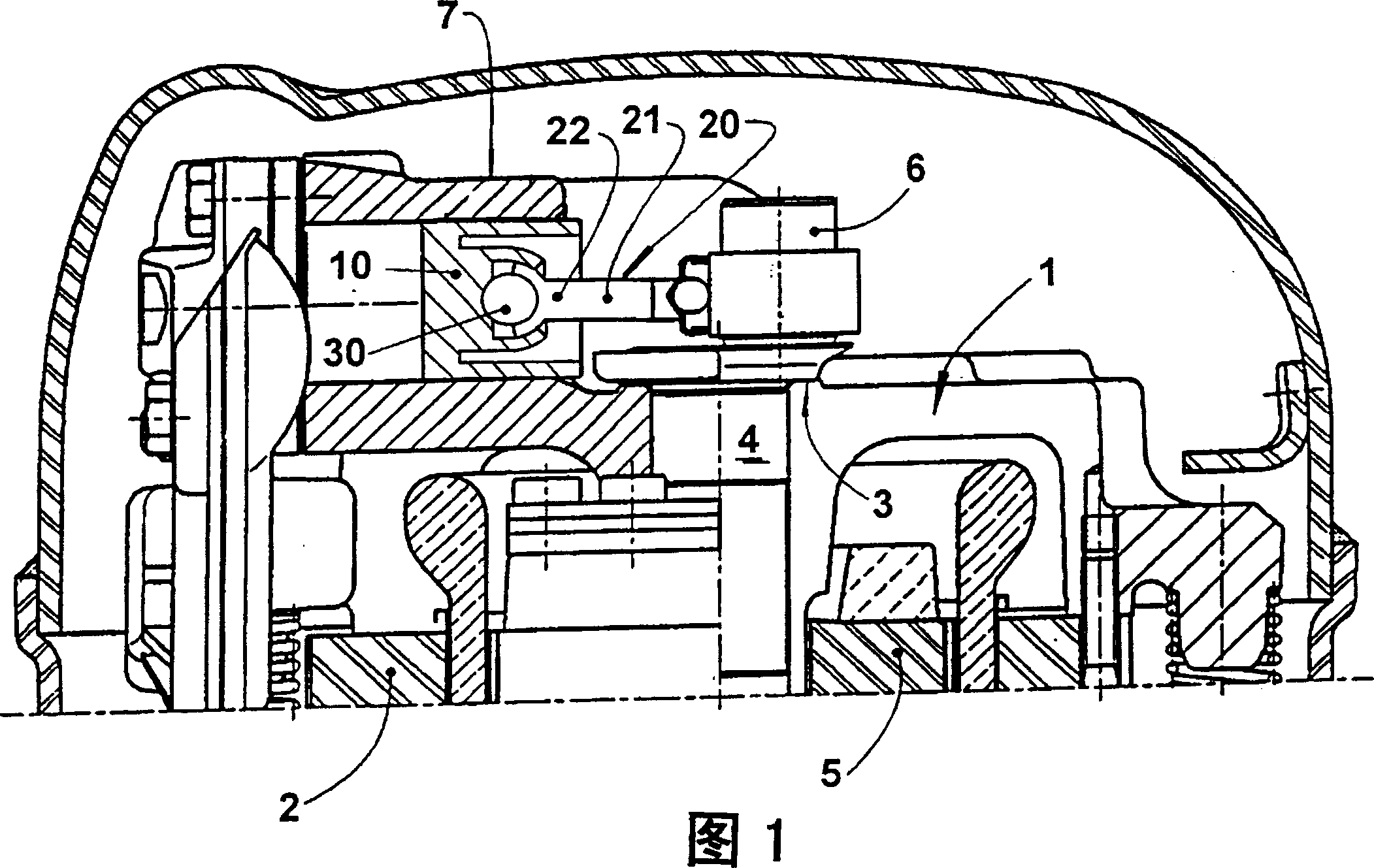

[0015] As shown in Figure 1, the reciprocating compressor of the motor-compressor assembly usually installed in a closed housing includes: a base 1 on which a stator 2 of an electric motor is installed and a bearing 3 supporting a crankshaft 4 is installed The rotor 5 of the motor is mounted on the lower part of the crankshaft, and an eccentric part 6 is provided on the upper end of the crankshaft.

[0016] The base body 1 also holds a cylinder 7 inside which houses a piston 10 traveling in a direction perpendicular to the axis of the eccentric 6 .

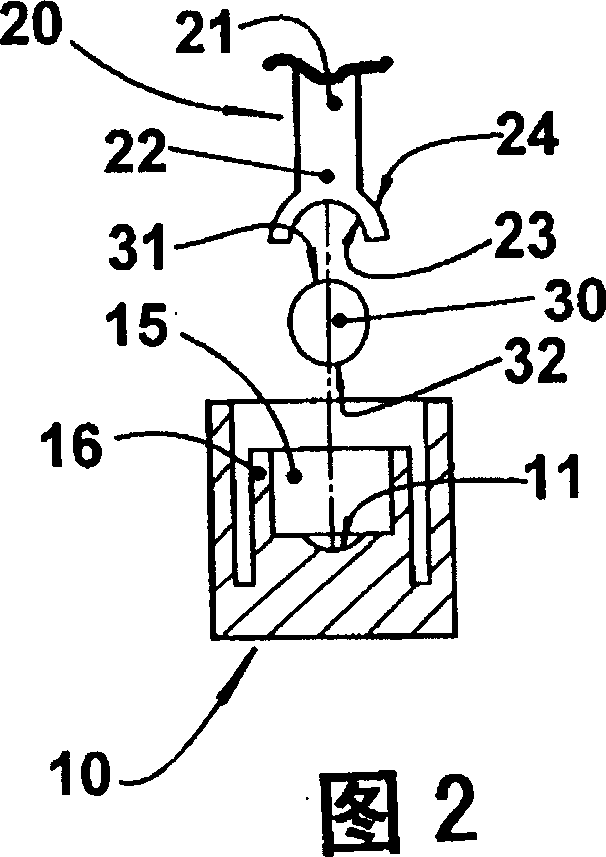

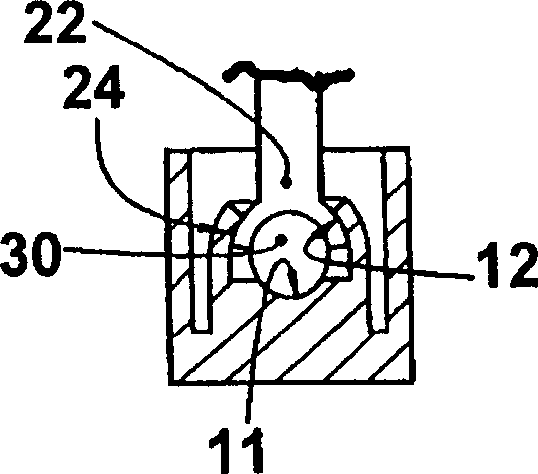

[0017] The connection between the piston 10 and the crankshaft 4 is achieved by articulated connection to the piston 10 of a connecting rod 20 with a rod 21 having an end 22 , the other end of which is mounted to the eccentric 6 , for example in a conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com