Curved surface composite super resolution current-carrying tube

A super-resolution, curved surface technology, applied in the analysis of materials, surface/boundary effects, measurement devices, etc., can solve the problems of failure to achieve super-resolution detection of biological and metal micro-nano structures, limited application range, incomplete accuracy, etc. Filtering characteristics and anti-interference, simple and easy to use, the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: The sample 6 to be tested in this embodiment is a fluorescently stained biological sample.

[0042] A hollow curved surface carrier is used, and at least one metal layer and a dielectric layer are arranged alternately to form a composite structure. The metal-dielectric multilayer composite curved surface structure needs to be constructed as a spherical geometry or a cylindrical geometry, so as to effectively prevent light from passing through different distances. The phase difference caused by different attenuation. The sample to be tested is placed in the cavity.

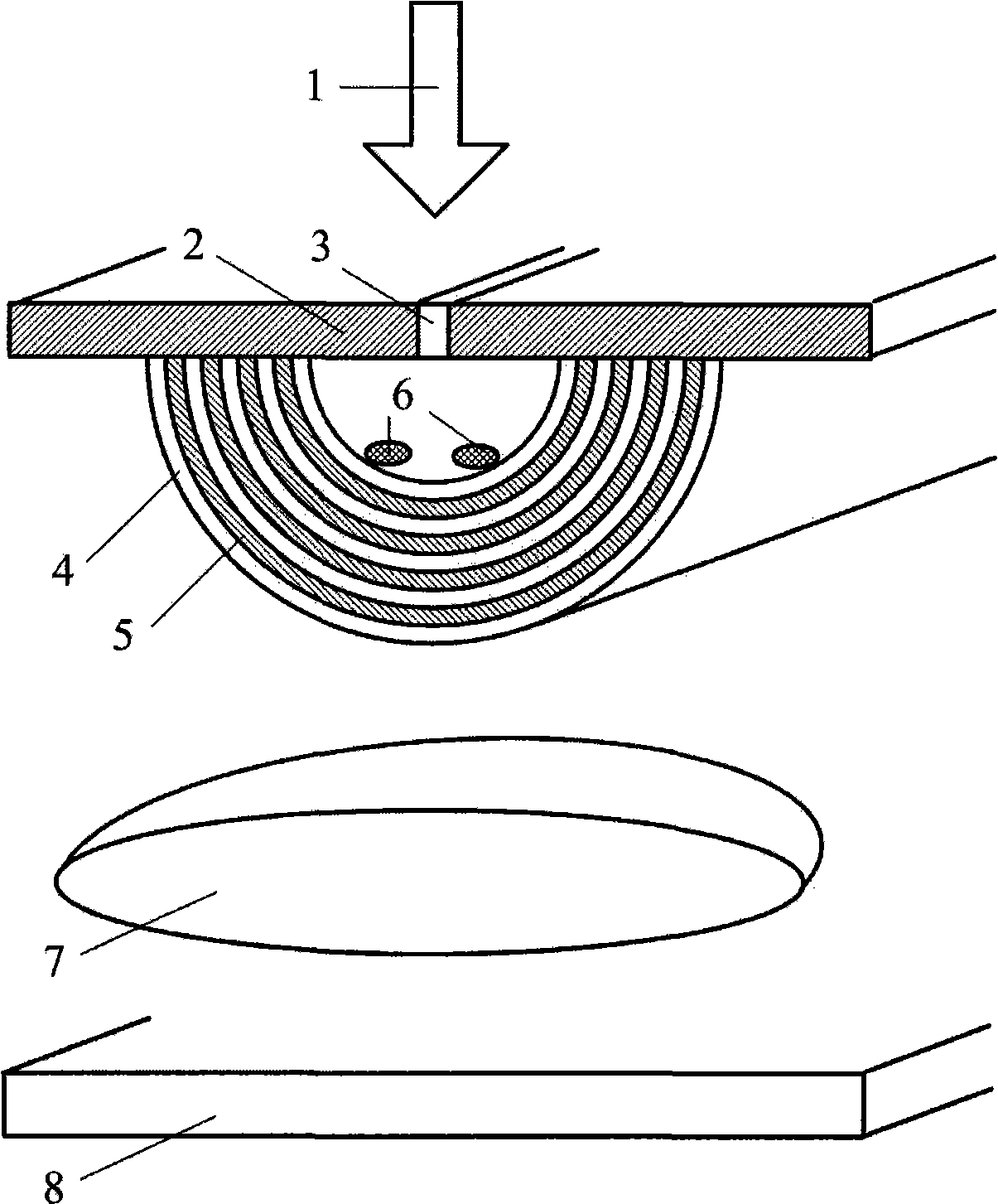

[0043] see figure 1 , in this embodiment, the curved surface carrier is a hollow semi-cylindrical body formed along the axial section, and the section is covered with a light-shielding layer 2 .

[0044] The light-shielding layer 2 selects chromium Cr with a thickness of 50nm, or other media with a transmittance of 0; on the light-shielding layer 2, a 50nm-wide light-transmitting slit 3 is op...

Embodiment 2

[0049] Embodiment 2: In this embodiment, the sample 6 to be tested is a metal nanoparticle sample.

[0050] The structure of the current-carrying tube is the same as above, see figure 1 . In this embodiment, the curved surface carrier is a hollow semi-cylindrical body formed along the axial section, and the section is covered with the light-shielding layer 2 . The light-shielding layer 2 selects chromium Cr with a thickness of 50nm, or other media with a transmittance of 0; on the light-shielding layer 2, a 50nm-wide light-transmitting slit 3 is opened along the axial direction of the semi-cylindrical body. This structure is to shield the light beam. Avoid irradiating the excitation light directly onto the imaging screen, which will affect the observation.

[0051] The light-transmitting slit 3 is located at the central axis of the current-carrying tube, and the irradiating light 1 can only enter the current-carrying tube from the slit, which is equivalent to a line light so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com