Plug type plugging device

A plug-in device and plug-in technology, which is applied in the field of plug-in plug-in devices, can solve the problems of cumbersome actual operation, low safety, and short-circuit stealing electricity by unscrupulous personnel, achieving screw-free fixing, reasonable structural design, and avoiding The effect of removing the meter and powering off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

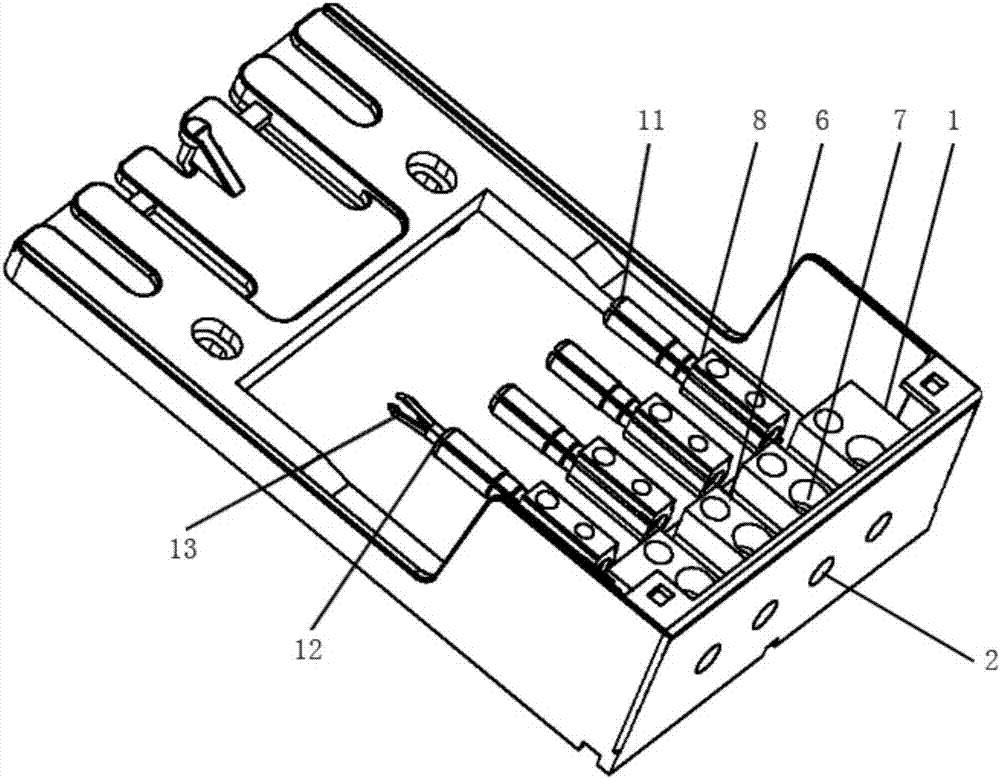

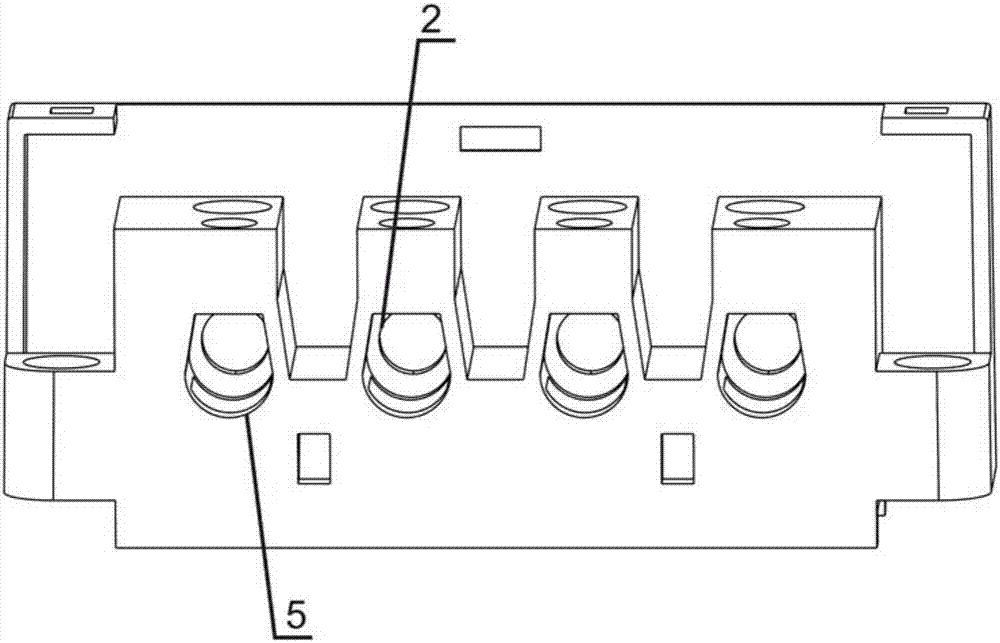

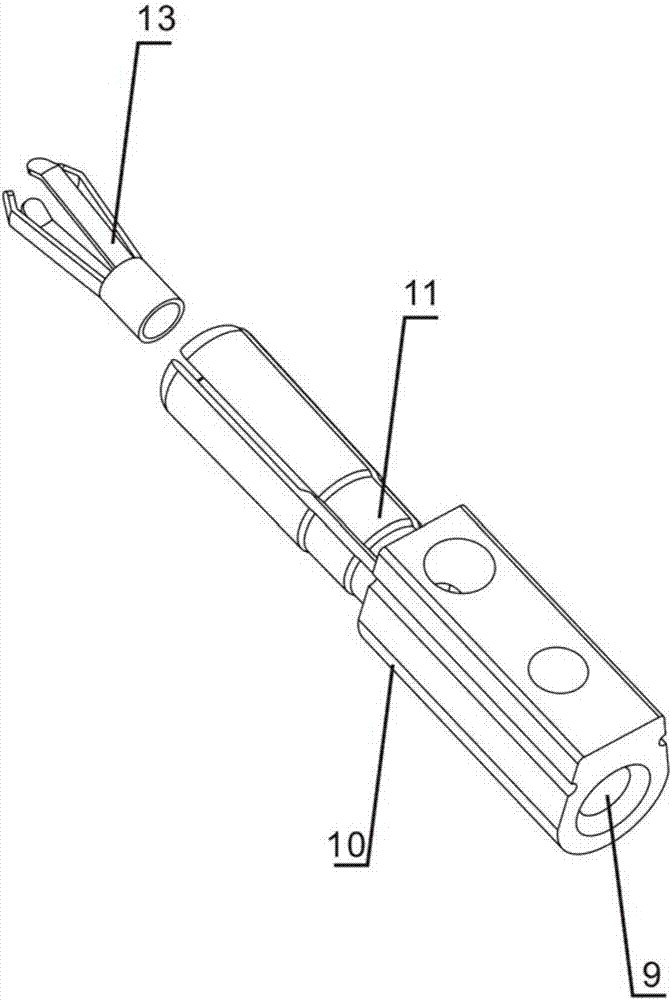

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The preferred embodiment of a pluggable plug-in device of the present invention shown includes: a base 1, a terminal 8 and a spring claw 13, and its structural characteristics: the base 1 is provided with a wiring hole 2, and the wiring hole 2 is equipped with There is a copper sheath 3 for the wire, an insulating sheath 4 is provided at the lower part of the copper sheath 3, a key-shaped end hole 5 is provided at the base 1, two or more sets of watch positions 6 are provided at the base 2, and an upper part of the watch position 6 is provided with There is a detection hole 7, the bottom of the terminal 8 is provided with an inner hole 9, the lower part of the terminal 8 is a cylinder 10 with a boss, and the cross section is key-shaped, the upper part of the terminal 8 is set as a round table plug 11, and the round table plug 11 is set as an open cross groove structure, and the opening width of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com