Energy-saving easily-changeable high-temperature microwave heating chamber and manufacturing method thereof

A microwave heating cavity and easy-to-replace technology, which is applied in microwave heating and other directions, can solve the problems of easy breakage of resistance wire, silicon carbon rod, silicon molybdenum rod, small heating area of heating element, and low microwave heating efficiency, so as to achieve good safety , Low manufacturing cost, easy maintenance and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

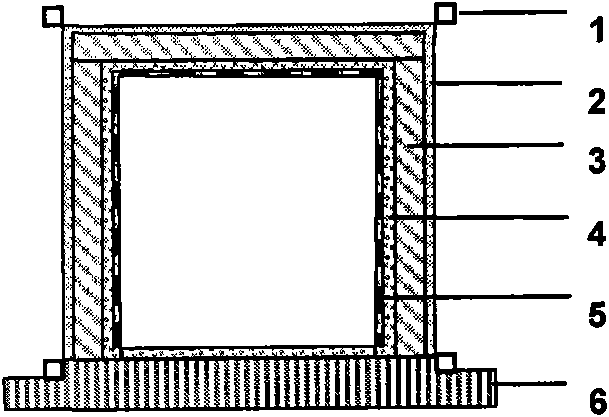

[0039] The first embodiment of the present invention will be described in detail below in conjunction with accompanying drawing 1 .

[0040] Fig. 1 is a schematic diagram of the "energy-saving easily replaceable high-temperature microwave heating chamber" and its components in the first embodiment of the present invention. The high-temperature microwave heating chamber in this embodiment is composed of a metal frame 1, a wave-transparent hardening layer 2, a wave-transparent heat insulation layer 3, a high-temperature microwave absorbing coating 4, a porous thin metal plate 5, and a base 6 from the outside to the inside. The five form a cube-shaped cavity 8 with an opening at the bottom. The cavity 8 cooperates with the base 6 as a whole to form a complete heating cavity. The manufacturing method is as follows:

[0041] (1) The porous thin metal plate 5 is a heat-resistant and oxidation-resistant steel plate with a thickness of 2mm and a grade of 2080, and is welded into a cav...

Embodiment 2

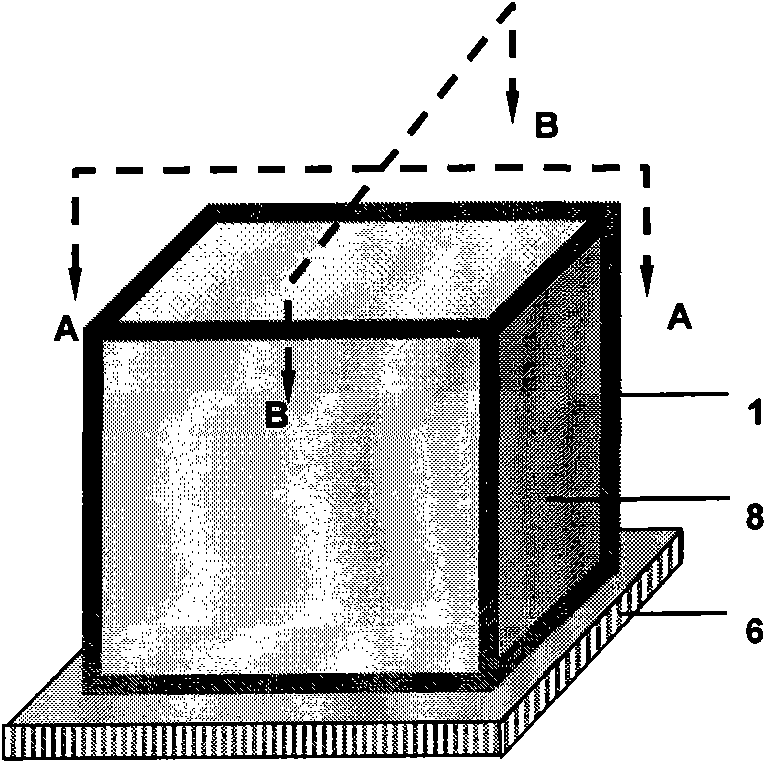

[0053] The second embodiment of the present invention will be described in detail below in conjunction with accompanying drawing 2 .

[0054] Fig. 2 is a schematic diagram of the "energy-saving easily replaceable high-temperature microwave heating chamber" and its components according to the second embodiment of the present invention. The high-temperature microwave heating cavity in this embodiment is composed of a wave-transparent hardening layer 2, a wave-transparent heat-insulating layer 3, a high-temperature microwave absorbing coating 4 and a base 6, wherein the first three form a cylindrical cavity 8 with an open bottom , the cavity 8 is taken as a whole and cooperates with the base 6 to form a complete heating cavity, and its manufacturing method is as follows:

[0055] (1) Zirconium-containing aluminum silicate blanket is selected for the wave-transmitting heat-insulating layer 3, and a suitable size is cut out, and then a cylindrical cavity in the shape shown in Figur...

Embodiment 3

[0063] The third embodiment of the present invention will be described in detail below in conjunction with accompanying drawing 3 .

[0064] Fig. 3 is a schematic diagram of the "energy-saving easily replaceable high-temperature microwave heating chamber" and its components according to the third embodiment of the present invention. The high-temperature microwave heating cavity in this embodiment is composed of a wave-transparent heat-insulating layer 3, a high-temperature microwave-absorbing coating 4 and an upper cover 7, wherein the first two form a cubic cavity 8 with an opening above, and the cavity 8 As a whole, it cooperates with the upper cover 7 to form a complete heating chamber, and its manufacturing method is as follows:

[0065] (1) Zirconium-containing silicate ceramic fiber is selected for wave-transparent heat insulation layer 3, and professional manufacturers are entrusted to use molds to produce integrated zirconium-containing aluminum silicate plate cavity a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com